Wouldn't a pragmatic methodology be to set the timer to get a faint red glow in a dark room and use that as the minimum annealing time and to find the meltdown time and use that as the high-end time you should never reach. If you get good results with the minimum time just continue to use that if not increase the time incrementally until you get results that you like. I think the goal for most people is consistent neck tension which is a combination of neck hardness and sizing. Then an expensive hardness tester isn't needed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Induction brass annealer redux

- Thread starter Gina1

- Start date

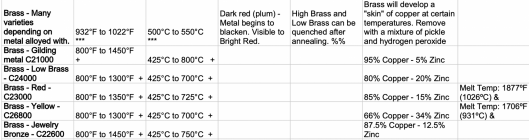

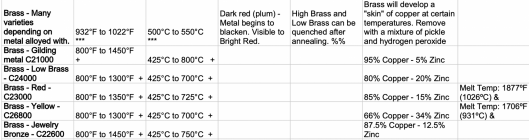

I don't think I posted a link to this useful table of annealing temps and colors of various metals

Here's a snip of the section re brass. Columns 2 and 3 are the annealing temp range. The next column describes the color associated with that range. So from that faint, dull red to bright red. If you're into any sort of orange you're going too far.

bulletin.accurateshooter.com

bulletin.accurateshooter.com

Here's a snip of the section re brass. Columns 2 and 3 are the annealing temp range. The next column describes the color associated with that range. So from that faint, dull red to bright red. If you're into any sort of orange you're going too far.

Cartridge Brass Alloys Revealed by X-Ray Spectrometers « Daily Bulletin

Are there significant metallurgical differences in the alloys used in various brands of cartridge brass? The answer is yes, and we have proof. Using a state-of-the-art X-Ray Fluorescence Spectrometer, some tech-savy Wisconsin shooters recently analyzed the alloys in seven different types of...

This works okay if you are using brass of the same cartridge and head stamp, but even within the same head stamp, times can very between manufacturer cartridge lots, depending on the exact composition of the brass. The time method does not work unless what you are annealing is all nearly identical. I have thousands of 5.56 NATO cartridges of various head stamps and the time-to-glow can vary between 2.5 and 4.0 seconds. This is the reason for looking at a solution other than time to determine proper anneal. I have found the temp sensor to be the perfect solution for my needs.Wouldn't a pragmatic methodology be to set the timer to get a faint red glow in a dark room and use that as the minimum annealing time and to find the meltdown time and use that as the high-end time you should never reach. If you get good results with the minimum time just continue to use that if not increase the time incrementally until you get results that you like. I think the goal for most people is consistent neck tension which is a combination of neck hardness and sizing. Then an expensive hardness tester isn't needed.

That makes sense. IMO there are 3 reasons to anneal brass. To prolong the case life, make resizing easier, less spring back and force and to get more consistent neck tension. Using mixed lots of brass you still get 2 of the three. How well does the flame sensor work? Can you throw in a 223 vs a 338 Lapua only adjusting for height and the flame sensor would work it magic?

Yes, exactly. I anneal my 223 and my 300 WBY, only adjusting for the height of the brass. The flame sensor setting is the same. That is the beauty of the flame sensor, I no longer have to worry about coming up with the correct time for each type of case.That makes sense. IMO there are 3 reasons to anneal brass. To prolong the case life, make resizing easier, less spring back and force and to get more consistent neck tension. Using mixed lots of brass you still get 2 of the three. How well does the flame sensor work? Can you throw in a 223 vs a 338 Lapua only adjusting for height and the flame sensor would work it magic?

I am not aware of a way to do it without using the Arduino or some other type of microprocessor.Is there a way to implement the flame sensor in a unit with the basic Sestos timer, or are you required to go with an Arduino?

Thats what I figured...

I do have an Arduino or two floating around here somewhere, but I don't have any interest in making a full-fledged process controller out of it , but if there was a way to make a simple temperature monitor controlling a relay that can be used to trigger a stop or drop command in my existing setup, that would be handy (and the Arduino routine to manage that should be relatively simple...if you are already familiar with the functioning of the flame sensor).

I do have an Arduino or two floating around here somewhere, but I don't have any interest in making a full-fledged process controller out of it , but if there was a way to make a simple temperature monitor controlling a relay that can be used to trigger a stop or drop command in my existing setup, that would be handy (and the Arduino routine to manage that should be relatively simple...if you are already familiar with the functioning of the flame sensor).

That would be an ideal and less complicated set up. I will just have to stick with my 950, 1000 degree tempilaqThats what I figured...

I do have an Arduino or two floating around here somewhere, but I don't have any interest in making a full-fledged process controller out of it , but if there was a way to make a simple temperature monitor controlling a relay that can be used to trigger a stop or drop command in my existing setup, that would be handy (and the Arduino routine to manage that should be relatively simple...if you are already familiar with the functioning of the flame sensor).

The flame sensor is an analog output.I don't use the sestos timer but couldn't the flame detector trip the pause input? Then reset to start another case?

itchyTF

Gold $$ Contributor

itchyTF

Gold $$ Contributor

Looks like the 4 pin types also have analog output.

So, are you guys using the analog output or the digital output to sense a case anneal is complete?

I would imagine that the digital output (0 or 1) would work only if the sensor trips at exactly the correct/desired temperature (or can that trigger value be set?), AND that 1 signal could be used as a trigger (or trigger a relay for a trigger signal).

Alternatively, the analog output would rise as temperature rises and you could determine the output value approximating the desired trip temperature on the Arduino and then have the Arduino trigger a relay to output a trigger signal.

I just ordered a flame sensor with 4 pins so that I would have the option to use whichever one functioned best, I just don't know which method I should investigate first...

I would imagine that the digital output (0 or 1) would work only if the sensor trips at exactly the correct/desired temperature (or can that trigger value be set?), AND that 1 signal could be used as a trigger (or trigger a relay for a trigger signal).

Alternatively, the analog output would rise as temperature rises and you could determine the output value approximating the desired trip temperature on the Arduino and then have the Arduino trigger a relay to output a trigger signal.

I just ordered a flame sensor with 4 pins so that I would have the option to use whichever one functioned best, I just don't know which method I should investigate first...

Okay, that makes sense...

Stupid Follow-up Question: Can the flame sensor be run in isolation (no Arduino) with 3.3-5VDC power input and the digital output triggering a relay? (in this case, with the digital output signal going 'low', the relay in question would be held in the 'closed' position and the normally closed contacts would be used to trigger the 'stop' on the timer)

Stupid Follow-up Question: Can the flame sensor be run in isolation (no Arduino) with 3.3-5VDC power input and the digital output triggering a relay? (in this case, with the digital output signal going 'low', the relay in question would be held in the 'closed' position and the normally closed contacts would be used to trigger the 'stop' on the timer)

Last edited:

The advantage of the digital output is that it's easier. The front end of the A/D converter on the Arduino isn't the best especially if your using multiple analog inputs. You have to give some time spacing (delays) between each analog input or you can run into problems depending on the input impedance of each input. Basically the "hold" capacitor doesn't have time to discharge while the A/D switches from one analog input to the next (only one A/D converter exists and is shared among the analog inputs). If we use an I2C input this also adds cycle time and more programming overhead and response lag (don't know if anyone is offering an IR sensor with such an output).

On my first build I was trying to use Joules as a way to trigger versus just time but I was getting natural variations just from the overall time it takes to calculate Joules as the analog inputs for the amps and voltage effected the value.

Here is a good read on the Arduino analog inputs although it doesn't get into the issue above and is more about resolution, drift and accuracy;

On my first build I was trying to use Joules as a way to trigger versus just time but I was getting natural variations just from the overall time it takes to calculate Joules as the analog inputs for the amps and voltage effected the value.

Here is a good read on the Arduino analog inputs although it doesn't get into the issue above and is more about resolution, drift and accuracy;

Why You Need an Analog Front End and How to Set It Up

The analog input to an Arduino Uno has a resolution of only 10 bits. On a 5V scale, this is only about 1 mV of sensitivity. If you need more sensitivity, don’t look at another microcontroller. Look at adding an analog front end to your Arduino.

www.nutsvolts.com

Yes, with the correct setup. Would have to draw it out. They make relay modules for the Arduino with pins already on them to connect to the Arduino. You could connect the flame sensor board above to the relay board as long as the correct pullup or pulldown resistor or resistors are in the circuit (if any are even required). Most of these outfits have the schematics.Okay, that makes sense...

Stupid Follow-up Question: Can the flame sensor be run in isolation (no Arduino) with 3.3-5VDC power input and the digital output triggering a relay?

Just to add to itchyTF comment which is an important one, if you get one of the modules already setup for an Arduino output it should have the TTL input necessary to trigger the relay. If you just purchase a bare relay you would probably be spending more money anyway, the Arduino kits are already setup and not that expensive.

Last edited:

Similar threads

- Replies

- 74

- Views

- 47,364

- Replies

- 0

- Views

- 1,576

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.