You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Induction brass annealer redux

- Thread starter Gina1

- Start date

On amazon you can get a cabinet lock from uxcell DC 12V 0.6A with a 11.4mm stroke. Before I went with a rotary solenoid I used one that was 10mm stroke. The issue was it got to close to the coil and would start heating up. It only supported 1/2 the case but that was all that was needed. One could easily on the diagonal striker drill and thread a hole and add a sheet metal bracket that could attach to a piece of Phenolic board to support the shell. This would get the metal parts far enough away from the induction coil so it would not heat up. Not much to design but takes up space compared to a shorter stroke solenoid and a pivot arm. The rotary solenoid really makes it easy but they cost a lot for a new unit so I can't recommend it, I got a used one of Ebay.You are not the first to bring bring the solenoid up.. About after a year after the build was published the company discontinued it. This is where you need to get creative.. There are several examples of where builders , in the thread sheets, used leverage, operated by a short through solenoid to operate the trap door.

It's a challenge or you can try to make your own light weight spring.

again

good luck

Try this one, just copy the description into the search window on eBay.You might be able to find something here -

solenoids, electromagnets, driver electronics & controls, magnets, wire, and other engineering supplies

Online Shopping for Solenoids, Electromegnets, Driver Electronics and Controls, Wire- Choose from a complete line of standard electro-mechanical components and other related Engineering Materials.www.electromechanicsonline.com

itchyTF

Gold $$ Contributor

I did that and got “No exact match found” and no image like you posted.Try this one, just copy the description into the search window on eBay.

DC12V Linear Motion Push Pull Tubular Solenoid Electromagnet 200g /10mm #2

View attachment 1304632

try amazon

Mine is actually eBay Australia. Sorry, I should have mentioned that.

The one above from dskogman will work. Whatever you select just ensure that there is a method of attaching the trapdoor to the shaft. Some of the solenoids do not have a thread or any holes in the shaft. The ones here are 15mm throw, which is good as my sample was only 10mm.

The one above from dskogman will work. Whatever you select just ensure that there is a method of attaching the trapdoor to the shaft. Some of the solenoids do not have a thread or any holes in the shaft. The ones here are 15mm throw, which is good as my sample was only 10mm.

I'm trying to calibrate my IR sensor at about ~1000 F for further annealing control. 1000 F Ttempilaq is not available on the market. May be I should determine it by the glowing of the brass or by some other methods.

Any reliable suggestions will be appreciated.

Thanks

Any reliable suggestions will be appreciated.

Thanks

The big problem with this is that it ignores the fact that peak temperature will be different at different points on the brass - in large part because of the thickness of the brass but also because of where the energy/heat is being applied. To take the first, a cartridge wall is much thicker one shoulder width down the case wall (from the shoulder junction) than at a turned neck (or worse, a chamfered case mouth). I'll bet you can be well-assured that if the case wall one shoulder length down hits 750F then everything above it gets MUCH hotter. You can exaggerate this by placing your indicator near the bottom of the case. The bottom line is that regardless of where you place your indicator you will have little accurate idea of what's happening further up. It's all a big guess unless you can place an accurate measurement device at precisely where you want it AND have a very targeted delivery of energy/heat.I posted the link in post #2410 of this thread, but here is is again along with the link giving the formula to calculate the temperature/time needed for annealing.

Deformation and Annealing of Cartridge Brass

Copper and its alloys are among the most malleable metals and alloys in existence. Cartridge brass, Cu – 30% Zn, has been used for many years to produce cartridge cases for ammunition due to its superior cold forming characteristics. This article shows the microstructure and hardness of...vacaero.com

Enjoy!

I did not want the tedious task of sorting the cases by headstamp, which lead to the flame sensor (Teyleten Robot 3.3V-5V IR Infrared Flame Sensor 4 Pin Infrared Detection Module Detecting Distance 80cm, 10 pack for $6.31). Now no matter what case I put into the annealer, it is annealed just long enough to start glowing (approximately 1000F).

But where on the case does the sensor focus? The shoulder is shrouded by the work coil. If the little bit of visible neck hits 1000F what temp does the shoulder get to, for example?

My sensor is calibrated to stop annealing when the neck and top of shoulder just begin to glow. The sensor is pointed at the neck. If you understand the temp/time curve, you are better to get a little hot and be on the flat top of the curve then to be a little cool and be on the steep slope of the curve. Obviously one does not want to get so hot as to melt the case. With the short time the induction annealers are using, the body and base of the case will not get hot enough for long enough to anneal them.I'm trying to calibrate my IR sensor at about ~1000 F for further annealing control. 1000 F Ttempilaq is not available on the market. May be I should determine it by the glowing of the brass or by some other methods.

Any reliable suggestions will be appreciated.

Thanks

I am using a double wound coil and the top of my case sits flush with the top of my coil so that the energy is focused at the neck/shoulder junction. My sensor is focused on the upper neck of the case and I stop annealing when the top of the shoulder just begins to glow. The sensor cannot see my shoulder, but I can looking down my coil. I slowly adjusted my sensor setting until I (not my sensor) can just see the shoulder begins to glow. With my configuration and cartridge-in-coil placement, the neck and shoulder glow simultaneously. The beauty is, the setting is the same for all my cases, 5.56 Nato though .300 Weatherby, regardless of headstamp. The only thing I adjust now is the insert for the case diameter and the distance from the base to coil so that the case mouth is always flush with the top of my coil.But where on the case does the sensor focus? The shoulder is shrouded by the work coil. If the little bit of visible neck hits 1000F what temp does the shoulder get to, for example?

Last edited:

I would rather have my annealing on the hotter side than on the cooler side. Understanding the temp/time curve, you want to be on the flat part of the curve (hotter) and not on the steep part of the curve (cooler) to provide more consistency from case to case. In the short time induction annealers impart their energy to the neck/shoulder, the body/base will not get sufficiently hot to anneal. As long as MUCH hotter is not melting the brass (1700 F) then you should be good. There is a wide range on the flat part of the time/temp curve (above approx. 1000F) where a large temp change will not produce a significant difference in annealing.The big problem with this is that it ignores the fact that peak temperature will be different at different points on the brass - in large part because of the thickness of the brass but also because of where the energy/heat is being applied. To take the first, a cartridge wall is much thicker one shoulder width down the case wall (from the shoulder junction) than at a turned neck (or worse, a chamfered case mouth). I'll bet you can be well-assured that if the case wall one shoulder length down hits 750F then everything above it gets MUCH hotter. You can exaggerate this by placing your indicator near the bottom of the case. The bottom line is that regardless of where you place your indicator you will have little accurate idea of what's happening further up. It's all a big guess unless you can place an accurate measurement device at precisely where you want it AND have a very targeted delivery of energy/heat.

I'm trying to calibrate my IR sensor at about ~1000 F for further annealing control. 1000 F Ttempilaq is not available on the market. May be I should determine it by the glowing of the brass or by some other methods.

Any reliable suggestions will be appreciated.

Thanks

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Here is some temp indicating fluid

The key word is consistency, regardless of the difference in hardness from the top to bottom of the neck. So far, my annealing practice is similar - the moment the shoulder junction starts glowing the time's up. My SD-s for various calibers are well under 10 fps.I would rather have my annealing on the hotter side than on the cooler side. Understanding the temp/time curve, you want to be on the flat part of the curve (hotter) and not on the steep part of the curve (cooler) to provide more consistency from case to case. In the short time induction annealers impart their energy to the neck/shoulder, the body/base will not get sufficiently hot to anneal. As long as MUCH hotter is not melting the brass (1700 F) then you should be good. There is a wide range on the flat part of the time/temp curve (above approx. 1000F) where a large temp change will not produce a significant difference in annealing.

However, not all brass is manufactured equal. By using temperature indicator I should be able to pinpoint 1000 F and then keep it for 1.88 sec according to Reese on the range formula (by pulsing the inductor say +/- 5% around 1000 F).

It should be kept in mind that the IR sensors do not focus on a single small point. As long as it is installed firmly and all adjustments are made, at that position it is very reliable for our purposes. It should be noted that the streaming data from the sensor has small variations. It needs to by averaged for a short period of time.

I think it would be really good if you guys could see how your approach aligns with monitoring current. See my post of almost a year ago (which in turn posted info I had posted even earlier)

See here

We are very confident that AMP's Aztec process monitors this current and then backs off the duration according to a formula. You can see that the change in current draw is very linear. In that post I made a rough estimate for time to 750F but of course you could do the same for 1000F or any other target. It would be very interesting to see how this correlates with your 1000F detection via IR.

See here

We are very confident that AMP's Aztec process monitors this current and then backs off the duration according to a formula. You can see that the change in current draw is very linear. In that post I made a rough estimate for time to 750F but of course you could do the same for 1000F or any other target. It would be very interesting to see how this correlates with your 1000F detection via IR.

Last edited:

BTW @VenatusDominus your post here reiterated stuff I had posted quite some time earlier as well. But note that you went on to deploy a double-layer work coil. The following provides more information on estimating the inductance of such "multilayer" coils. (Note, also the optimization associated with a Brooks coil.)

Of course the frequency of oscillation of the ZVS board and any coil combo can be measured easily with an oscilloscope as I did with mine. Lo' and behold it matched an estimation of the interaction of the capacitance of the board and an estimation of the inductance of my (single-layer) work coil. For a known frequency of oscillation and known capacitance, you can estimate the inductance of your work coil.

Were I to redo my annealer I'd very much want to deploy a gapped ferrite typology because the flux is concentrated across the air gap in the ferrite and thereby provides a very targeted heating area. However, I'm not sure I have the enthusiasm to do a redesign and would probably just plop for an AMP instead. One has to have great passion for the design and implementation of a GinaErick build at this level to make it worthwhile. I take my hat off to those pushing the limits here.

Of course the frequency of oscillation of the ZVS board and any coil combo can be measured easily with an oscilloscope as I did with mine. Lo' and behold it matched an estimation of the interaction of the capacitance of the board and an estimation of the inductance of my (single-layer) work coil. For a known frequency of oscillation and known capacitance, you can estimate the inductance of your work coil.

Were I to redo my annealer I'd very much want to deploy a gapped ferrite typology because the flux is concentrated across the air gap in the ferrite and thereby provides a very targeted heating area. However, I'm not sure I have the enthusiasm to do a redesign and would probably just plop for an AMP instead. One has to have great passion for the design and implementation of a GinaErick build at this level to make it worthwhile. I take my hat off to those pushing the limits here.

Last edited:

I think it would be really good if you guys could see how your approach aligns with monitoring current. See my post of almost a year ago (which in turn posted info I had posted even earlier)

See here

We are very confident that AMP's Aztec process monitors this current and then backs off the duration according to a formula. You can see that the change in current draw is very linear. In that post I made a rough estimate for time to 750F but of course you could do the same for 1000F or any other target. It would be very interesting to see how this correlates with your 1000F detection via IR.

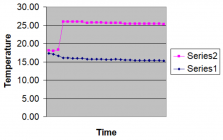

I melted the neck. The graphs (at the end of the process blue - Amps, red - IR reading) show that, indeed, the current begins decreasing, and in this case, just before the rising of the temperature.

PS I use ferrite core.

Have a look at post #2,628 - there is an almost perfect linear relationship between current measured at x seconds (I can easily predict current at target "temperature"using a current measurement at 0.2 second - way before any harm is done to a case) and the current measured at the time the case neck starts to glow (probably any temperature you set as "target" - but glow color, which is determined by temperature btw, is "easy" to visually see and use as reference point). Across different cases. It could be interesting to see if the guys using temperature measurement can reproduce/confirm that there is a linear relationship between a current measurement at some point in the beginning of the cycle and a current measurement when the ir sensor detects some tafrget temperature. Easy to "calibrate" (get constant and coefficient for a straight line) an annealer to make precice prediction of current at target temp for any case measuring just 2 different cases. Having found the function (linear), you can predict current at target for any case by just measuring the current at the same time you used to make the function - e.g. 0.2 second - and then just continue the cycle until calculated current has been reached. Realtime prediction.I think it would be really good if you guys could see how your approach aligns with monitoring current. See my post of almost a year ago (which in turn posted info I had posted even earlier)

See here

We are very confident that AMP's Aztec process monitors this current and then backs off the duration according to a formula. You can see that the change in current draw is very linear. In that post I made a rough estimate for time to 750F but of course you could do the same for 1000F or any other target. It would be very interesting to see how this correlates with your 1000F detection via IR.

Just to be clear - I'm not describing the linear increase of current during annealing of a case.

Last edited:

Similar threads

- Replies

- 74

- Views

- 47,312

- Replies

- 0

- Views

- 1,573

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.