CLR is not recommended for any metals other than chrome or stainless steel. I have heard reports that it can affect bluing if not removed quickly. That and it's incompatibility with other materials found on gun parts ( wood, painted, coated , or sealed surfaces) has led me to avoid it's use.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SUCCESS at Last - Carbon in throat removal

- Thread starter dstoenner

- Start date

jelenko

Gold $$ Contributor

So, the dark color is just the color of the surface of the metal?I don't think so. Look at the fine, regular, 90* to the bore lines, they look like snake scales. That's not carbon, that's fire cracking and you couldn't see them if you had a carbon layer still in there. Carbon looks like the surface of a burnt marshmallow, uneven, random, and non-reflective.

Thanks

urbanrifleman

Site $$ Sponsor

I have tried 90% of the products mentioned and found Gunk spray carb cleaner is the best chemical, and with a brass brush gets the job done without using an abrasive cleaner.

To tell you the truth, if a person cleans THOROUGHLY with a brinze brush and really strong penetrating oil, I do not think carbon builds up. If the person cleans thoroughly. Which is something on the order of 60 strokes per 100 rounds (but that is rough estimate).

Carb cleaner... don't get that on anything or it will strip anything it touches.

Yes sir. Steel just like most everything changes color when superheated. Also there is some color shift even from the bore scope light at certain angles. But if there was carbon you couldn't see the fine lines where the steel is cracking as it begins to degrade. It is minor right now, when it gets bad the lands will no longer be visible and the cracks will be more pronounced. Lands tend to go first as they are sticking up into the blast of heat from the charge and the bullet is pressing into them harder and eroding them faster.So, the dark color is just the color of the surface of the metal?

Thanks

I use this, Carbon Ring Remover. Only the front end past 45 degree angle is sharpened. Spin it it just cuts the built up ring. It bottoms out on the shoulder, since the reamer is not sharpened, it won't move the headspace. I specified it to be carbide as the HSS might not last cutting the hard carbon.

It cost me a couple of iterations working with JGS grinders to get what I want. If interested contact Sarah at JGS, she can talk through it. It is based on the Wylde reamer.

The 1st one we did was based on the TX JRs Reamer back in 2019. It is now being used by the team

It cost me a couple of iterations working with JGS grinders to get what I want. If interested contact Sarah at JGS, she can talk through it. It is based on the Wylde reamer.

The 1st one we did was based on the TX JRs Reamer back in 2019. It is now being used by the team

Last edited:

dstoenner

Silver $$ Contributor

The photos were of my barrel after being cleaned using montana extreme bore cleaner then kroil/jb bore paste. I personally think that the black is polished carbon on top of the surface. The second picture shows streaks of black polished further down the barrel. Right now i am waiting for some bronze brushes to come in. I did get some KG1 and just put in my barrel a few hours ago. Pushed a tight patch and the patch is gray.Yes sir. Steel just like most everything changes color when superheated. Also there is some color shift even from the bore scope light at certain angles. But if there was carbon you couldn't see the fine lines where the steel is cracking as it begins to degrade. It is minor right now, when it gets bad the lands will no longer be visible and the cracks will be more pronounced. Lands tend to go first as they are sticking up into the blast of heat from the charge and the bullet is pressing into them harder and eroding them faster.

I’ll know more Thursday or so when the brushes come in and i can experiment a little.

stay tuned film at 11

David

On a 222 after cleaning with PatchOut, patches and nylon brush, the borescope showed the carbon ring, a couple wet patches of CarbOut and a 20 minute soak then nylon brush and the length of the ring was reduced by 1/2. I need to keep up on my cleaning/scoping to verify but first peek was encouraging.

dstoenner

Silver $$ Contributor

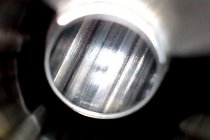

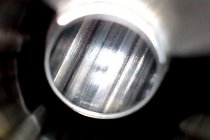

Update from the trenches. My bronze brushes came this afternoon. My barrel had been soaking in Kroil all night. I attached a 6mm bronze brush, dipped the brush in the kroil bottle and took 10 strokes. Then patched. OH MY GOODNESS was that patch black. I did it again with some Flitz. Mine is polish and I think you guys were saying to get flitz bore cleaner. So I cut down to 10 strokes again. Patched it all out. I can tell the carbon is thinner. I am making progress.

I tried O'Reilly for the Free All but they didn't have it nor does it seem that this store stocks it. Next is going to be Advanced Auto tomorrow.

Here are some pictures

First the throat

Next is about 5 inches down the bore

What do you think of KG-1 and work the bronze brush after I have soaked the bore and then let it sit?

I tried O'Reilly for the Free All but they didn't have it nor does it seem that this store stocks it. Next is going to be Advanced Auto tomorrow.

Here are some pictures

First the throat

Next is about 5 inches down the bore

What do you think of KG-1 and work the bronze brush after I have soaked the bore and then let it sit?

urbanrifleman

Site $$ Sponsor

Update from the trenches. My bronze brushes came this afternoon. My barrel had been soaking in Kroil all night. I attached a 6mm bronze brush, dipped the brush in the kroil bottle and took 10 strokes. Then patched. OH MY GOODNESS was that patch black. I did it again with some Flitz. Mine is polish and I think you guys were saying to get flitz bore cleaner. So I cut down to 10 strokes again. Patched it all out. I can tell the carbon is thinner. I am making progress.

I tried O'Reilly for the Free All but they didn't have it nor does it seem that this store stocks it. Next is going to be Advanced Auto tomorrow.

Here are some pictures

First the throat

View attachment 1261132

Next is about 5 inches down the bore

View attachment 1261136

What do you think of KG-1 and work the bronze brush after I have soaked the bore and then let it sit?

I don't think any of those chemicals make a difference at this point. Oil, brush, and abrasive. And way more strokes than you think.

urbanrifleman

Site $$ Sponsor

FYI. Just tried some Flitz Bore Cleaner - no noticeable difference vs Iosso or JB. It is messier.

I never tried Iosso with a bore scope. I found Flitz to be on the order of twice as effective as Jb. I'm sure they all work on a bronze brush.

jelenko

Gold $$ Contributor

Hmm. I'll try it again. More effective in removing that carbon is good.I never tried Iosso with a bore scope. I found Flitz to be on the order of twice as effective as Jb. I'm sure they all work on a bronze brush.

Exactly what i was gonna ask about.I've been using CLR on stubborn carbon. Works quite well.

I know i seen one well known shooter use it on their brakes, he warned me to never let the stuff touch blueing , but i often wonder if he uses it in his bores ?

urbanrifleman

Site $$ Sponsor

Best way to remove carbon is not to let it build up in the first place.

Very true.

We are in a new era of shooting because shooters of ordinary means can now all afford their own bore scope. With a Teslong bore scope we can prevent hard carbon by making sure that we have removed all powder fouling each time we clean.

A friend who has successfully used IOSSO on a soft nylon brush about every 100 rounds on a PPC burning LT32 has switched to a procedure involving Kroil at the start of every cleaning, and has been able to stop using IOSSO. He had gotten good barrel life and accuracy using the IOSSO, but I believe the incentive for coming up with another approach was the time it takes to completely remove abrasive cleaners from a barrel. Doing what he does with Kroil, every time he cleans has prevented an accumulation of powder fouling that would eventually become hard carbon.

Based on experience with a friend, I believe that removing extensive hard carbon is very problematic, even with the use of abrasives, and there is some risk of harming the barrel if you are not very careful, and perhaps even if you are.

A friend who has successfully used IOSSO on a soft nylon brush about every 100 rounds on a PPC burning LT32 has switched to a procedure involving Kroil at the start of every cleaning, and has been able to stop using IOSSO. He had gotten good barrel life and accuracy using the IOSSO, but I believe the incentive for coming up with another approach was the time it takes to completely remove abrasive cleaners from a barrel. Doing what he does with Kroil, every time he cleans has prevented an accumulation of powder fouling that would eventually become hard carbon.

Based on experience with a friend, I believe that removing extensive hard carbon is very problematic, even with the use of abrasives, and there is some risk of harming the barrel if you are not very careful, and perhaps even if you are.

Similar threads

- Replies

- 1

- Views

- 4,149

- Replies

- 83

- Views

- 7,590

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.