So where are we left? I don't think we have the answer. Some (including you) say hit glow (c950F) momentarily. Others think you need to hold 1000F for 1.88s. That's a considerable difference. Ambrell mentions 1250F (way above the Draper Point). Few have actually tested induction settings with hardness testing of the brass. AMP have done the work but of course have kept the results to themselves.

I think you are little off when you say that there is a considerable difference between 950F and 1000F.

The difference in The Draper Point by eye, without training or a reference on hardness, can be a little arbitrary. It is best taught in person but many folks figure this out on their own after a little trial and error.

If an expert shows you what to look for and how long, then odds are you would be able to repeat what they have shown you even without the benefits of a metallurgical laboratory or hardness measurements and get it right on the first try.

Because the neck temperature is climbing fast in this context, it will climb quickly from 950F to over 1000F and beyond. So, when you pause for a heartbeat at The Draper Point for a two count, you get that Goldilocks result but not because you had it at exactly 950 or 1000. Neck annealing has temperatures that are a moving value, not ones that have lots of dwell at some steady equilibrium.

Cartridge necks are thinner than standard metallurgical pucks used in standardized tests. Thin necks do not use the same heat-time schedules as thicker samples and the crystal boundaries move differently, so those mechanical properties change differently as well. Many standard charts in college textbooks do not apply to cartridge making. But there is no need to go this deep down the rabbit hole.

In the equation Reese published, the material constants will account for a thin neck, but even that equation isn't really adjusting for a specific hardness value. That and the Ambrell paper showing even higher temps, are best adjusted through trial and error using either hardness or seating force as feedback.

And a lot more folks have measured their hardness than you assume. Just like many folks measure their seating force, but more on that later.

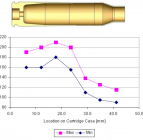

If we were to plot the other mechanical properties like modulus and yield, you would see they get us into good neck tension results as long as we are close to those spec hardness levels. It is those other properties that give us the "neck tension" we want as long as we also manage the friction coefficient.

As a hobbyist, a secondary goal is to nail the settings from session to session, but a primary goal is to get the results in the correct hardness range and not allow part to part variation. If a hobbyist is off by five or ten hardness points between sessions, it isn't the end of the world. After all, many folks do just fine without annealing at all.

Fired brass also has a complex oxide layer in the neck that factory brass does not. The grip on the bullet is a result of the friction coefficient times the forces from the brass. It is just as important to manage the friction coefficient as it is to manage the heat treat.

Ammo manufacturers have spent a lot of time and money on their production lines and their people. They don't publish what they consider private information and they require PIAs and NDAs from everyone who goes behind the curtains. It isn't up to those folks on the ground to decide what gets published in conference papers or at symposiums. One or two generic publications on ammo making are in the public domain and if you want to go down the rabbit hole most of what I have shared is in there or I couldn't say it here.

I'll try and link or share one of them here.

Ammunition Making by George Frost

You will find a few points at which he discusses several heat treatments, but he still doesn't give you an exact schedule or fine details.

My takeaway is that folks using induction or flame annealing can expect to spend some time in trial and error while using either hardness or seating force as the feedback. Even then, you need some skills and attention to detail or you will make things worse instead of better. YMMV