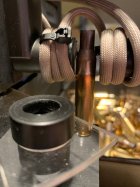

"A short interruption to engage / reengage the field can be adjust out." -> Yes - pulses. One way of taking care of local "overaccumulation" of heat (a (steep temperature gradient). I heard the AMP making ticking sounds - just like my home made annealer using pulses - and suspected it to use pulses or bursts. Engaging/re-engaging.@SGK

Further thoughts from your comment.

The shoulder has more mass. So needs more heat either by more current or more time.

The existing power supply is (more than) adequate

Higher current in one area has a lot of discussion. So this is hard or complicated.

More time is easier. This just requires some calibration runs for time.

Other issues maybe field collapse.

A short interruption to engage / reengage the field can be adjust out.

At least from a concept it looks doable.

I stumbled upon the manual for the AMP and their description of Aztec - and they actually write that Aztec codes are different from their standard codes.

In their news feed I also found (https://www.ampannealing.com/news/43/aztec-mode-coming-soon/)

"Aztec runs in a different manner to our standard programs, and they don’t correlate. It doesn’t do the series of pulses which you would be used to. It is quicker and quieter than our standard programs. The end result is the same neck and shoulder annealed hardness. Because it is quicker, about one millimetre less of the body down from the shoulder is annealed. That is just a "run out” area anyway, and is not significant."

Another "easy" way is adjusting the field, instead of pulses adjusting voltage? which would make the field stronger or weaker/ more or less current drawn.