Hello

My expected values curves come from two sources.

- First one comes from "AMP", give a look at this page :

https://www.ampannealing.com/articles/52/salt-bath-annealing--does-it-work-/

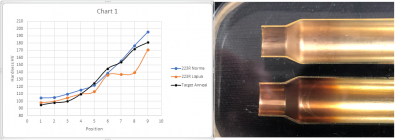

View attachment 1240156

I've found also on their web site this publication:

https://www.ampannealing.com/articles/40/annealing-under-the-microscope/

NOTE; the cases were sized after annealing, resulting in work hardening

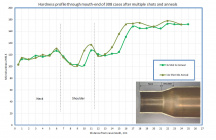

View attachment 1240157

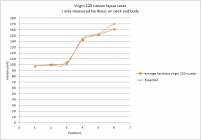

- second one comes from own measurements on 220 russian virgin lapua cases.

On virgin cases I only measured the hardness on neck and just after the shoulder. Why? because i had not prepared for those cases the right support for measuring shoulder.

3 measurements on neck, first 1 mm after the neck end, second one in the middle of the neck and last one 1 mm before the shoulder.

On body, measurements were done past the point of the shoulder, first one 1 mm after the shoulder, second one 3 mm further and last one 3 mm further.

View attachment 1240155

I'm not a mettalurgist, just a mechanics teacher.

The expected values shown on my graphs come from my own measurements and from web sites publications.

But for me and for many people, the purpose of accurate annealing is to produce consistent and repeatable neck and shoulder hardness.

Note: As I said many times 6 PPC cases with a .262" neck is a very big challenge for getting a linear annealing from end of the neck to the body.

For sure, if one day I can test hardness on 308 or 300 win mag annealed cases I'm pretty sure that annealing will be more consistent, I mean more linear because the neck walls are pretty more thicker.

Today I was curious and annealed some 300 win mag cases (winchester brand).

The shoulder got red at the same time with the neck, But I didn't measure hardness.

I hope one day I'll have enough time.

But that begs the question I posted quite some time ago about the validity of your "expected values" curve. Your prior tests and comments suggesting "not enough annealed" would appear to be invalidated if the annealing of this popular, recently purchased, annealer is correct.

I said "not enough annealed" because my reference was what I saw on web sites and my own measurements.

Obviously, theory is theory, The reality on the ground is quite different.

Therefore, I'm pretty satisfied by the results I obtained with my home made machine, that means that Gina Eric conducted very successful researches. Thanks so much to them.

Then why am I so interested by the use of tempilaq?

If I can find a relation between hardness and cooking temperature, I should no longer have to return to laboratory.

I hope my english is good enough for explaining the results I obtained.

Best regards

Patrice