bobm

Silver $$ Contributor

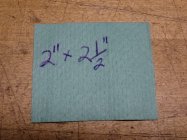

I make them from those heavy blue, green or white shop paper towels from auto parts stores. Pretty easy using wood glue and the slotted jag. Spread the glue sparingly with a bent paper clip. Apply it in the web area, makes it rigid for easy slipping into the slot from either end. Apply it in a couple of places along the rolling. I make about two dozen at a time pretty fast. The size shown is a 1/4" slotted rod with the rolls about 3/8". They compress just right to get into .30 and .284 chamber necks.Where you get them pre made rolls?

Attachments

Last edited: