Ned Ludd

Silver $$ Contributor

Here is more detailed information about the tuner (i.e. increments, Erik's process to set the tuner):

As can be seen from the image, the tuner increments go from 0 to 50, being numbered every 5 on the tuner body. Further, the thread pitch is 20 TPI, indicating 0.050" linear movement per turn, and 0.001" linear movement per single increment/hashmark.

FWIW - I have several of Erik's original tuners. One major difference between the two versions is that the original tuner has 25 increments per full turn, or exactly half the number found on the V2. Other differences are largely confined to the external appearance and the mechanism by which friction is created to prevent random [unwanted] turning of the device. Functionally, they should work exactly the same with respect to tuning and barrel harmonics.

From what the OP described, I can see a few potential differences between what I perceive should be the "correct" method for testing per Erik's instructions, and the way it was actually carried out. The instructions indicate the tuner should be installed ~ flush with the muzzle, an index mark created, and be turned outward during the tuning process. If I understand the OP correctly, the tuner was turned inward from the index mark. That probably shouldn't make a huge difference in finding a "tune" window as long as there was sufficient travel to turn the tuner inward at least one full turn. The reason for turning it outward is that there may not be sufficient inward travel depending on the installation process. Regardless, one can find a tune window twirling the tuner in either direction.

However, the reason I mentioned the suggested installation and process for setting the tuner is because of some more recent comments and groups posted by the OP, where the tuner apparently was not attached. The idea is to carry out what most would call "standard load development practices" initially, with the tuner screwed down to the "0" setting. In other words, the approach should be to set the tuner at "0", then carry out charge weight and seating depth testing until a well-tuned load has been achieved before carrying out a tuner test. From the more recent posts regarding groups with the tuner not attached, it is unclear to me exactly how the original tuner testing was carried out; i.e. was the load developed with the tuner attached and screwed down to "0"? Or with the tuner not attached? I raise these questions because it might make a difference in how the final results manifest during the testing process.

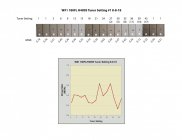

My experience with Erik's original tuner design is that one should observe at least one optimal tune window within a single rotation. In my hands, such a window may be as much as 5-7 single increments wide as shown in the attached tuner test image, but that would be totally dependent on the cartridge/load/rifle setup. Although I have carried out numerous tuner tests that generated similar results, the test shown below is one where the results were quite clear and that I actually could find the image file to post herein. Below the fired groups is a graph of Group Size versus Tuner Setting as an example, where I used three-shot groups and moved the tuner 3 increments (out of 25 total per turn) per group, for a total of [almost] two complete turns. As can be seen from the image, the "optimal" window (~15-21) also occurs during the second turn of the tuner, at very close to the equivalent point in the rotation cycle as was observed on the first turn.

My point here is that moving the tuner 5 increments between each group as outlined in the testing procedure may be too coarse. I view this situation as not totally unlike seating depth testing, where using too large or coarse a seating depth increment during the testing process can sometimes lead to completely missing seating depth optima. It may be worth repeating the tuner test, being sure the load is well-tuned/developed, with the tuner attached and set at "0", then using increments of 2.5 per group, rather than 5. To be sure, repeating the test in that manner won't necessarily guarantee different results, but at least it will be unlikely that any potentially optimized settings won't be missed. I would also add to this that it is highly desirable to have the best (i.e. mildest) possible conditions during the test, and that if a shot is pulled by the shooter as evidenced via the reticle, it must be recorded during testing. If you think you pulled a shot or were caught by a wind change even a couple times during the testing and didn't record it, it can make the final results exceedingly difficult to interpret.

As can be seen from the image, the tuner increments go from 0 to 50, being numbered every 5 on the tuner body. Further, the thread pitch is 20 TPI, indicating 0.050" linear movement per turn, and 0.001" linear movement per single increment/hashmark.

FWIW - I have several of Erik's original tuners. One major difference between the two versions is that the original tuner has 25 increments per full turn, or exactly half the number found on the V2. Other differences are largely confined to the external appearance and the mechanism by which friction is created to prevent random [unwanted] turning of the device. Functionally, they should work exactly the same with respect to tuning and barrel harmonics.

From what the OP described, I can see a few potential differences between what I perceive should be the "correct" method for testing per Erik's instructions, and the way it was actually carried out. The instructions indicate the tuner should be installed ~ flush with the muzzle, an index mark created, and be turned outward during the tuning process. If I understand the OP correctly, the tuner was turned inward from the index mark. That probably shouldn't make a huge difference in finding a "tune" window as long as there was sufficient travel to turn the tuner inward at least one full turn. The reason for turning it outward is that there may not be sufficient inward travel depending on the installation process. Regardless, one can find a tune window twirling the tuner in either direction.

However, the reason I mentioned the suggested installation and process for setting the tuner is because of some more recent comments and groups posted by the OP, where the tuner apparently was not attached. The idea is to carry out what most would call "standard load development practices" initially, with the tuner screwed down to the "0" setting. In other words, the approach should be to set the tuner at "0", then carry out charge weight and seating depth testing until a well-tuned load has been achieved before carrying out a tuner test. From the more recent posts regarding groups with the tuner not attached, it is unclear to me exactly how the original tuner testing was carried out; i.e. was the load developed with the tuner attached and screwed down to "0"? Or with the tuner not attached? I raise these questions because it might make a difference in how the final results manifest during the testing process.

My experience with Erik's original tuner design is that one should observe at least one optimal tune window within a single rotation. In my hands, such a window may be as much as 5-7 single increments wide as shown in the attached tuner test image, but that would be totally dependent on the cartridge/load/rifle setup. Although I have carried out numerous tuner tests that generated similar results, the test shown below is one where the results were quite clear and that I actually could find the image file to post herein. Below the fired groups is a graph of Group Size versus Tuner Setting as an example, where I used three-shot groups and moved the tuner 3 increments (out of 25 total per turn) per group, for a total of [almost] two complete turns. As can be seen from the image, the "optimal" window (~15-21) also occurs during the second turn of the tuner, at very close to the equivalent point in the rotation cycle as was observed on the first turn.

My point here is that moving the tuner 5 increments between each group as outlined in the testing procedure may be too coarse. I view this situation as not totally unlike seating depth testing, where using too large or coarse a seating depth increment during the testing process can sometimes lead to completely missing seating depth optima. It may be worth repeating the tuner test, being sure the load is well-tuned/developed, with the tuner attached and set at "0", then using increments of 2.5 per group, rather than 5. To be sure, repeating the test in that manner won't necessarily guarantee different results, but at least it will be unlikely that any potentially optimized settings won't be missed. I would also add to this that it is highly desirable to have the best (i.e. mildest) possible conditions during the test, and that if a shot is pulled by the shooter as evidenced via the reticle, it must be recorded during testing. If you think you pulled a shot or were caught by a wind change even a couple times during the testing and didn't record it, it can make the final results exceedingly difficult to interpret.