"It's the Indian, not the arrow"

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Precision matthews 1440 2sm

- Thread starter Rockchuck

- Start date

I never said the 1340 wasn't any better or worse.

Absolutely not, I will take credit for that assumption.

That's why they weigh 1500 pounds instead of 3 to 4000 pounds like the 1440's that you listed.

Weight is certainly important. Not the only thing, but you get what you get with the Taiwan machine. However, I didn't know some where made in China. I'm guessing you mean mainland/Shenzhen/Beijing, right? I didn't know some of the machines were made there. I will let my friend know, just in case he's not aware of it. That would be a deal breaker for me. I thought the PM lathes were all made in Taiwan.

Dave Tooley has done hundreds if not thousands of winning barrels on a 10 inch Nardini lathe and he will tell you that a 10 to 12 inch lathe is more "Nimble" and better suited to gun work. I have a 1340 and couple of 12x36 lathes and I do my barrels on the 1340 and other projects on the other lathes. But I'm no expert, I don't do that many barrels per year anymore.

I mentioned my mainlathe is a 10x20, which has 13-1/2" swing. It weighs 4000 lbs., so I understand what you're talking about with weight. My machine is mostly cast iron, which is not done very often anymore. If I didn't have it, I would probably look for some other vintage American lathe.

I'm building a new shop, and I have a South Bend 10L in a yard I rent, tarped. This will be a great lathe, but needs some cleanup. It has metric transposition gears and has both sets of charts on the headstock from the factory. Also has a lever clutch on the apron, a D1-4 spindle, and a hardened bed. It is not super new, it's a 1958, but I know that's a fine vintage, since I was born that year!

That Chinese PM 1440 2sm is actually just fine for barrel work. Gordy Gritters used chinese Grizzly's for years and turned out fabulous work. There is no doubt the Taiwan Lathe's are of higher quality, But the chinese ones of today are very good machines and if that's what your budget can afford, I think they are fine.

Now I'm embarrassed as I didn't know some of the Grizzlies were made in Mainland, but I honestly don't follow the market very well, I don't machine as a profession, just as a hobby. Pappa Grizzly is the epitome of what destroyed America. He bought the South Bend name and has probably made his investment back by selling the original shipping invoice for $25. Amazing how many people will do that. Prior to him buying the name Leblond would give that info out for free, and while I don't have a printout, I have a South Bend 9A that came out of the Levi Strauss factory in SF when it closed. My Rivett 1020F came out of the Hershey factory...not to digress, the point was hundreds if not thousands of lathe owners are willing to spend $25 on that info and that has probably paid for his purchase and then some. Now he gets to market one of the most well known lathe names for free, and owns it legally. He does this with Chinesium parts, and therein is why America is going down the toilet.

Now if you want to hog off a 0.250 or better at a good feed rate all day long you better get a heavy duty lathe. The brass worm gear on the apron is the weak point on the light duty lathes and you aren't going to hog off material for long on one of the light duty lathes before something is damaged. You might get away with it for a while.

Well, you can do fine work on a South Bend 9A if you're patient. I think they're great machines and pretty much what is considered entry level lathes.

That Chinese PM 1440 2sm is actually just fine for barrel work.

Yeah, it just sucks for our ego...I don't think my friend knows that.

I see a few higher priced PM lathes in the 1440, one is the 1440GT and the 1440HVT-2, both of those are what they call Ultra Precision Lathes and in the spec it does in fact state, "100% Made in Taiwan, no shortcuts taken, built to a very high level of quality", where that is missing from the other PM1440 lathes down around the $7500-$8500 level, so the 1440GT is $11.6k and the 1440HVT-2 is $14k.

Thank you very much for mentioning that, gonna give my friend a call shortly.

That Chinese PM

Just got off the phone with my friend. I think it shows that we all think differently. He was already aware that it was a Chinese lathe he was looking at. He doesn't mind it, and I can understand, just that I would pony up the extra money for the Taiwan machine. I think he will end up buying the Chinese machine.

Looking at the whole picture, PM makes it easy for people as they offer a reasonable shipping. In reality, it's slightly less than market. I saw it was $499 per machine, $79 lift gate fee.

If I was in that position, which I am not, I would think hard about finding a Yam/Webb/Kingston/et-al in really nice condition at auction. But I have an entire shop of old vintage industrial machines, so don't see myself needing to do that.

Another area he felt was important that I didn't was the spindle bore. My friend was very strong on having a 2" spindle bore, where I would be fine with 1-9/16".

OP, if you're still following this, I noticed the SM is a 1440 gunsmith lathe also, and there's also a 1340GT and a 1440GT that are made in Taiwan. You should compare the 1440SM against the 1340GT, IMO. That's a much better/fair comparison. They're around the same price, 1340GT is about $800 cheaper. If you need the size of the 1440, compare the 1440SM vs 1440GT, which is over $3k difference.

Actually those "Southbend" Lathes that Grizzly sells today are made in Taiwan by "Sunmaster" and are superior to any vintage southbend of the past. Old American iron is cool and all that. But my friend has an "Acra" made by Sunmaster and its an Awesome machine.Absolutely not, I will take credit for that assumption.You have raised some concerns with your post, read on...

Weight is certainly important. Not the only thing, but you get what you get with the Taiwan machine. However, I didn't know some where made in China. I'm guessing you mean mainland/Shenzhen/Beijing, right? I didn't know some of the machines were made there. I will let my friend know, just in case he's not aware of it. That would be a deal breaker for me. I thought the PM lathes were all made in Taiwan.

I mentioned my mainlathe is a 10x20, which has 13-1/2" swing. It weighs 4000 lbs., so I understand what you're talking about with weight. My machine is mostly cast iron, which is not done very often anymore. If I didn't have it, I would probably look for some other vintage American lathe.

I'm building a new shop, and I have a South Bend 10L in a yard I rent, tarped. This will be a great lathe, but needs some cleanup. It has metric transposition gears and has both sets of charts on the headstock from the factory. Also has a lever clutch on the apron, a D1-4 spindle, and a hardened bed. It is not super new, it's a 1958, but I know that's a fine vintage, since I was born that year!

Now I'm embarrassed as I didn't know some of the Grizzlies were made in Mainland, but I honestly don't follow the market very well, I don't machine as a profession, just as a hobby. Pappa Grizzly is the epitome of what destroyed America. He bought the South Bend name and has probably made his investment back by selling the original shipping invoice for $25. Amazing how many people will do that. Prior to him buying the name Leblond would give that info out for free, and while I don't have a printout, I have a South Bend 9A that came out of the Levi Strauss factory in SF when it closed. My Rivett 1020F came out of the Hershey factory...not to digress, the point was hundreds if not thousands of lathe owners are willing to spend $25 on that info and that has probably paid for his purchase and then some. Now he gets to market one of the most well known lathe names for free, and owns it legally. He does this with Chinesium parts, and therein is why America is going down the toilet.

Well, you can do fine work on a South Bend 9A if you're patient. I think they're great machines and pretty much what is considered entry level lathes.

You are right though, South Bend is just a name anymore that Grizzly bought the rights to, Shiraz the owner of Grizzly is a good man in my opinion, He came to this country and met someone at the range who was a Gunsmith and he visited this mans house and afterward he knew he just had to have a lathe. Long story short he bought and repaired lathes and sold them until it grew into the business that he has today. I am going off of memory so I may have butchered part of the story.

Shiraz is also a long range competitor and contributes to the shooting sports. I feel he is a good man.

Grizzly is also an excellent source for parts for many import machines no matter what brand they may have on them. I have bought many repair parts from them. I think PM is also a very good company, But I tried to buy parts from them for another import machine and I had the part numbers that would interchange with the PM machines but I was told they only sell parts for their machines.

I called another company and I was quoted $2700.00 for the parts from the actual importer with their badge on the machine. I was able to find the parts by looking at similar looking machines on Grizzly's website and I bought the parts from Grizzly for around $500.00 for the same exact parts. Grizzly is awesome, Very nice people on the phone there too.

I must admit, I would love to have one of those "Rivett" Lathes.

LeBlonde doesn't support their lathes, Surface grinders or anything else they sell near as well as Grizzly supports their products and for that matter they support most of the other import lathes as well.

Last edited:

But my friend has an "Acra" made by Sunmaster and its an Awesome machine.

I also know someone with an Acra and it is a nice machine. Where are those made? Do you know?

I have a couple friends that bought Hardinge clones, one a Kent and another a Sharp, both are fine lathes. I learned how to thread on the Kent. I don't have much experience with Grizzly, and didn't mean to cast a shadow on them. They always seem to offer more value than any of the competition at a lower price. Some of the stuff is a home run, and others are flops. More so, he's a smart businessman.

LeBlonde doesn't support their lathes,

I bet they would if you have deep enough pockets, which is not me.

I have always planned to sell the 2nd South Bend 10L I have, after I found the newer one I have. The first one had a threaded spindle on it. I have a donor D1-4 spindle in need of some TLC to put in it.

I must admit, I would love to have one of those "Rivett" Lathes.

It's a great machine, one of the best I have. I paid top dollar at the time, but Hershey had a bunch of Monarch 10EE tooling in the cabinet, including a brand spanking NOS buck chuck with a D1-3 backplate. I was able to sell the tooling to recover about half my investment. In the end, it cost me about $3k. It sits a tad low, I'd like to raise it...I will move it eventually, but don't want to mess with it right now. It lives with a lever dial Deckel FP1 from the '60s. I like vintage machines.

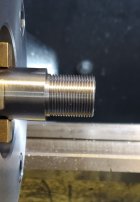

Yes, I bought it specifically for doing chambers, it's come in very handy for several other projects tooDo you make barrels with yours? I like to buy one have no experience with a lath

Yes the Acra my friend has is made in Taiwan. But Acra is like Grizzly in that they have an upper line of machines and a lower line. The upper lines are made in Taiwan and the lower line made in Mainland China.I also know someone with an Acra and it is a nice machine. Where are those made? Do you know?

I have a couple friends that bought Hardinge clones, one a Kent and another a Sharp, both are fine lathes. I learned how to thread on the Kent. I don't have much experience with Grizzly, and didn't mean to cast a shadow on them. They always seem to offer more value than any of the competition at a lower price. Some of the stuff is a home run, and others are flops. More so, he's a smart businessman.

I bet they would if you have deep enough pockets, which is not me.

I have always planned to sell the 2nd South Bend 10L I have, after I found the newer one I have. The first one had a threaded spindle on it. I have a donor D1-4 spindle in need of some TLC to put in it.

It's a great machine, one of the best I have. I paid top dollar at the time, but Hershey had a bunch of Monarch 10EE tooling in the cabinet, including a brand spanking NOS buck chuck with a D1-3 backplate. I was able to sell the tooling to recover about half my investment. In the end, it cost me about $3k. It sits a tad low, I'd like to raise it...I will move it eventually, but don't want to mess with it right now. It lives with a lever dial Deckel FP1 from the '60s. I like vintage machines.

Here is the lathe my friend has. Which is made by "Sunmaster" In Taiwan Same as Grizzlies Southbend.

My 1340 is a Kent Usa Lathe and I have been very happy with it.

Every time I see pics of your little Jet I keep thinking I will happen into one someday. I have the 12 inch model of this lathe although its wore out and I put it out in the container.I use this 90s vintage Jet 10x24 for chambering AR15 barrels from blanks, factory turned to 1.00x. Last count I chambered close to 100 AR15 barrels on this little guy. I even thread straight in with it because the compound is sort permanently set for 223 taper boring.

View attachment 1507846

LVLAaron

Gold $$ Contributor

That is a real hoss of a machine.I use this 90s vintage Jet 10x24 for chambering AR15 barrels from blanks, factory turned to 1.00x. Last count I chambered close to 100 AR15 barrels on this little guy. I even thread straight in with it because the compound is sort permanently set for 223 taper boring.

View attachment 1507846

The "T" in the model number designates Taiwan on the PM models.Yeah, it just sucks for our ego...I don't think my friend knows that.

I see a few higher priced PM lathes in the 1440, one is the 1440GT and the 1440HVT-2, both of those are what they call Ultra Precision Lathes and in the spec it does in fact state, "100% Made in Taiwan, no shortcuts taken, built to a very high level of quality", where that is missing from the other PM1440 lathes down around the $7500-$8500 level, so the 1440GT is $11.6k and the 1440HVT-2 is $14k.

Thank you very much for mentioning that, gonna give my friend a call shortly.

HAPPY NEW YEARS GUYS, HOPE YOU ALL HAD A GOOD ONE!

That’s a neat lathe Bamban! What’s the headstock measurement on that, can you get to 16”? That thing would be as handy as a pocket on a shirt.

I will look. I know an 18 barrel will go between spiders. I did my 18" 300WM through it. It is suppressed, kind of handy.

Edit: @Judd if you thread the spindle tail, close to the lock ring for outboard spider, and make a short screw on front spider, unlike what I did, yes, you can run a 16" barrel through it.

What I did, I replaced the lock ring with the outboard spider. It added an inch to the end of tail. For the front, I bolted an inch thick spider to a faceplate.

Now that you asked, I might change my set up, just like I articulated above.

FYI, I do have a bunch of barrel extensions for both ends to work on my shorter barrels.

Last edited:

Yes the Acra my friend has is made in Taiwan.

Very nice, my friend has one that looks like that but I think it's a 1640. That looks like a nice lathe.

My 1340 is a Kent Usa Lathe and I have been very happy with it.

I mentioned I used a Kent USA Hardinge clone that a friend of mine owns, he taught me how to thread on his Kent and I applied that to my little South Bend 9A. He also had a Kent USA knee mill, and it was a very nice machine. He has a couple other machines, but nothing to speak of, but he did spend quite a chunk on tooling.

Those Kent USA machines are pretty nice, IMO. I was building joinery handsaws and turned my first bronze split nut on his Kent lathe, and milled a slot in them for spanners. I used the mill to fly cut some aluminum, but ended up getting help from someone else at one of the local community colleges. I built a fixture to slot bronze for the backs and my South Bend for the split nuts out of the same 932 bronze.

My plan is to use a heavy 10 to chamber my bolt actions/barrels, since I can't chamber through the headstock on the Rivett easily. BTW, I noticed that PM supplies a rear spider on their "Gunsmith" lathes. That's a nice touch to get people up and running quickly.

My first barrels I did on an old Southbend 13 single tumbler lathe from 1937. I chambered and threaded using the steady rest. That lathe is long gone, Went out of here in parts through Ebay years ago. Made enough off of the parts to buy a nicer machine.Very nice, my friend has one that looks like that but I think it's a 1640. That looks like a nice lathe.

I mentioned I used a Kent USA Hardinge clone that a friend of mine owns, he taught me how to thread on his Kent and I applied that to my little South Bend 9A. He also had a Kent USA knee mill, and it was a very nice machine. He has a couple other machines, but nothing to speak of, but he did spend quite a chunk on tooling.

Those Kent USA machines are pretty nice, IMO. I was building joinery handsaws and turned my first bronze split nut on his Kent lathe, and milled a slot in them for spanners.

My plan is to use a heavy 10 to chamber my bolts, since I can't chamber through the headstock on the Rivett easily. BTW, I noticed that PM supplies a rear spider on their "Gunsmith" lathes. That's a nice touch to get people up and running quickly.

Doing barrels through the headstock is the only way to go. But if you cant then using the steady works.

xr650rRider

Silver $$ Contributor

BTW, I noticed that PM supplies a rear spider on their "Gunsmith" lathes. That's a nice touch to get people up and running quickly.

Where you seeing that? Some of the Grizzly's do but unless a recent addition, PM doesn't. All the specs are on the website.

Where you seeing that? Some of the Grizzly's do but unless a recent addition, PM doesn't. All the specs are on the website.

PM-1440-2SM 14″x40″ Gunsmith Lathe – Precision Matthews Machinery Co.

Similar threads

- Replies

- 53

- Views

- 7,362

- Replies

- 65

- Views

- 4,579

- Replies

- 12

- Views

- 1,394

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.