I have an induction annealer I want to sell that I made years ago using the info on this site....all that needs to be completed is the solenoid mechanism to drop the brass. I have two solenoids for this...the mech just needs to be finished. It is working as pictured and was programmed using a plc as I recall ...program was posted here ...I made this to use with my dillon press and it turns on and off the outlet at the bottom. Make me a reasonable offer.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Induction brass annealer redux

- Thread starter Gina1

- Start date

itchyTF

Gold $$ Contributor

This belongs in the classifieds and you need to list a price.I have an induction annealer I want to sell that I made years ago using the info on this site....all that needs to be completed is the solenoid mechanism to drop the brass. I have two solenoids for this...the mech just needs to be finished. It is working as pictured and was programmed using a plc as I recall ...program was posted here ...I made this to use with my dillon press and it turns on and off the outlet at the bottom. Make me a reasonable offer.

will do...This belongs in the classifieds and you need to list a price.

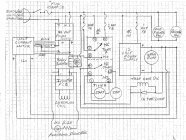

This is the original schematic (so very long ago). Many changes have taken place. I hope this will be a starting point for you. Read the posts in the tread to get ab idea on how to improve on the design. ie replace the 110 volt AC fans with 12 volt DC fans, etc.

Good luck

Gina1

Good luck

Gina1

Attachments

Foreigner,Hi Guys,

Maybe it is a stupid question, but since i am an electric virgin,who is trying to build the original ginaerick anaeler i could use some help.

Can anyone tell me how to connect the sestos please?

Hope some one can get me going.

Thanks anyway

It appears that you have a different timer from the original. The label you attached to your first post indicates your timer has only 1 set of contacts. The original timer had 2 sets of contacts. One set controlled the relay to the induction board, and the other set controlled the trap door solenoid.

I have attached a picture of the label on my timer. Hope this helps.

Hello to all!

I, like all members of this discussion, am trying to build myself an induction annealer for my expensive 6.5x47 Lapua cases.

I purchased a circuit complete with coil on AliExpress.

The circuit is a 1000W ZVS with 6 x 0.33uF capacitors.

Since its coil out to be too large for the cases, I purchased a second coil, of which I attach the link.

The coil is Color C, with 2 series of coils.

The standard coil, with the LCR circuit, measures 1.95uH.

The second coil that I purchased was 1.65uH.

I tried using 12V 50A car relays but these cannot handle the absorption of the ZVS circuit.

At the moment I am not equipped with an instrument that allows me to measure the absorption in Amperes or Watts. If you have any instrument to recommend I will gladly accept the advice.

The machine I would currently like to build would be very simple, I would do the loading of the cases manually.

However, the annealing and unloading of the cartridge case would be automatic.

I would use 2 timed relays connected in cascade and set for this purpose.

As soon as I manage to get the necessary components to make the creation less horrifying I will post some photos.

The material must arrive from China.

Thanks for reading me and sorry for my bad English, it's Google translator's fault

I, like all members of this discussion, am trying to build myself an induction annealer for my expensive 6.5x47 Lapua cases.

I purchased a circuit complete with coil on AliExpress.

The circuit is a 1000W ZVS with 6 x 0.33uF capacitors.

Since its coil out to be too large for the cases, I purchased a second coil, of which I attach the link.

The coil is Color C, with 2 series of coils.

The standard coil, with the LCR circuit, measures 1.95uH.

The second coil that I purchased was 1.65uH.

I tried using 12V 50A car relays but these cannot handle the absorption of the ZVS circuit.

At the moment I am not equipped with an instrument that allows me to measure the absorption in Amperes or Watts. If you have any instrument to recommend I will gladly accept the advice.

The machine I would currently like to build would be very simple, I would do the loading of the cases manually.

However, the annealing and unloading of the cartridge case would be automatic.

I would use 2 timed relays connected in cascade and set for this purpose.

As soon as I manage to get the necessary components to make the creation less horrifying I will post some photos.

The material must arrive from China.

Thanks for reading me and sorry for my bad English, it's Google translator's fault

Foreigner

This is the timer you wantSestos Digital Quartic Timer Relay Switch 100-240V B3S

Sestos Timer

itchyTF

Gold $$ Contributor

If I recall correctly, I think the target coil inductance is around 1 uH (give or take a little). For our purposes I believe the frequency should be around 100 - 120kHz.Hello to all!

I, like all members of this discussion, am trying to build myself an induction annealer for my expensive 6.5x47 Lapua cases.

I purchased a circuit complete with coil on AliExpress.

The circuit is a 1000W ZVS with 6 x 0.33uF capacitors.

Since its coil out to be too large for the cases, I purchased a second coil, of which I attach the link.

The coil is Color C, with 2 series of coils.

The standard coil, with the LCR circuit, measures 1.95uH.

The second coil that I purchased was 1.65uH.

I tried using 12V 50A car relays but these cannot handle the absorption of the ZVS circuit.

At the moment I am not equipped with an instrument that allows me to measure the absorption in Amperes or Watts. If you have any instrument to recommend I will gladly accept the advice.

The machine I would currently like to build would be very simple, I would do the loading of the cases manually.

However, the annealing and unloading of the cartridge case would be automatic.

I would use 2 timed relays connected in cascade and set for this purpose.

As soon as I manage to get the necessary components to make the creation less horrifying I will post some photos.

The material must arrive from China.

Thanks for reading me and sorry for my bad English, it's Google translator's fault

I would recommend a “quality” SSR for switching your DC source. NOT one from China.

Why not add a voltage and current meter for monitoring. They are not that expensive.

I would also suggest getting 1/8 inch diameter copper tubing and wind your own coils. Helpful to use the silicon/fiberglass sleeving to prevent shorts.

Hello Foreigner,Foreigner

This is the timer you want

Sestos Digital Quartic Timer Relay Switch 100-240V B3S

Sestos Timer

the Sestos on your link, of I don't make a mistake, had only 2 output.

I read that is necessary a Sestos quarti, is true?

I looked, on a pair of videos/realization, an other 4 relay the name are PTR4.

But for now I can manage all with and inexpensive pair of time delay relay.

Regards

Hello itchy TF,If I recall correctly, I think the target coil inductance is around 1 uH (give or take a little). For our purposes I believe the frequency should be around 100 - 120kHz.

I would recommend a “quality” SSR for switching your DC source. NOT one from China.

Why not add a voltage and current meter for monitoring. They are not that expensive.

I would also suggest getting 1/8 inch diameter copper tubing and wind your own coils. Helpful to use the silicon/fiberglass sleeving to prevent shorts.

ita possible that youre right, but the on board coil of the ZVS had 1,95uH inductance.

Ok for ssr.

Wich type of voltage and current meter can you suggest me?

Can you suggest info for make a coil with 1/8" copper tube?

Thanks

itchyTF

Gold $$ Contributor

The board can oscillate at different frequencies depending on the inductance. I believe the 100-120kHz range is good for the thickness of cartridge brass.Hello itchy TF,

ita possible that youre right, but the on board coil of the ZVS had 1,95uH inductance.

Ok for ssr.

Wich type of voltage and current meter can you suggest me?

Can you suggest info for make a coil with 1/8" copper tube?

Thanks

This would be an example of a volt/amp meter.

There are a number of inductance calculators onlne that could help you come up with a coil.

Here’s one -

Coil Inductance Calculator

Use this online calculator to determine the inductance of single-layer and multilayer air-core coils. Both metric and English units of measurement are supported.

www.66pacific.com

You might find a multilayer coil to be beneficial.

Hello,The board can oscillate at different frequencies depending on the inductance. I believe the 100-120kHz range is good for the thickness of cartridge brass.

This would be an example of a volt/amp meter.

There are a number of inductance calculators onlne that could help you come up with a coil.

Here’s one -

Coil Inductance Calculator

Use this online calculator to determine the inductance of single-layer and multilayer air-core coils. Both metric and English units of measurement are supported.www.66pacific.com

You might find a multilayer coil to be beneficial.

thanks for the various links , but i think that the real info like a photos, measurements, quotes, are too helpfull for me.

Regards

itchyTF

Gold $$ Contributor

Not sure what you mean. The link for the meter shows a photo.Hello,

thanks for the various links , but i think that the real info like a photos, measurements, quotes, are too helpfull for me.

Regards

The inductance calculator link has diagrams showing coil construction. It gives you the flexibility of dimensions to come up with the target inductance.

Here are a couple of pics but I can’t give dimensions since I’m not home. The wood blocks are to keep everything aligned while being stored. The black things (caps) are to keep insects out. Different inside diameters for different cases.

The SSR I used with a big heatsink.

Attachments

The machine on the photo are your?Not sure what you mean. The link for the meter shows a photo.

The inductance calculator link has diagrams showing coil construction. It gives you the flexibility of dimensions to come up with the target inductance.

Here are a couple of pics but I can’t give dimensions since I’m not home. The wood blocks are to keep everything aligned while being stored. The black things (caps) are to keep insects out. Different inside diameters for different cases.

The SSR I used with a big heatsink.

If yes, compliments!

I'm waiting for the 1/8" tube, and when arrive I can make some test.

Thanks for your support.

Regards

itchyTF

Gold $$ Contributor

I built the annealer in the photo for a friend. Mine is older but similar. Picture attached.

Originally the coolant tank was way too big so I cut it down. It’s still larger than necessary. I didn’t know how big it should have been so I overdid it.

Anneal time can be determined by either push wheel switches (9.99 sec max) or the flame sensor.

Originally the coolant tank was way too big so I cut it down. It’s still larger than necessary. I didn’t know how big it should have been so I overdid it.

Anneal time can be determined by either push wheel switches (9.99 sec max) or the flame sensor.

Attachments

Similar threads

- Replies

- 74

- Views

- 47,366

- Replies

- 0

- Views

- 1,576

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.