nsussf,

Not to open a can of worms or anything, but here is my offering

Simplest set up (in my opinion)

- adequately large power supply to power ZVS board (and only ZVS board) through large relay.

- large capacity relay (I like the DPDT double pole relay because it connects and disconnects both positive and negative power to ZVS simultaneously). The one I use has a relay switching capacity of 30A of 250VAC or 28VDC, but I've never had an issue switching the 48V/22A I use to power my ZVS.

- separate 12VDC power supply to control the large relay through the small relay on the timer board, any cooling fans and the coolant pump, and any other low voltage components you have.

- a simple timer board that will run on 12VDC and has at least a 0.1 second resolution for the timer annealing cycle and a relay to control the large relay.

This setup will let you run the process entirely manually, with the exception of the timer controling the ZVS run time to a 0.1 second resolution.

- Drop case in coil

- press start

- remove case when anneal complete

- repeat

I think the timer linked below will allow (with the correct programming) you to start it, then it will close its relay in order to anneal for the programmed time, then the relay will open and the anneal will stop, the timer will run for a programmed delay time, and then repeat the entire cycle over and over until stopped.

Again, this is my understanding from looking at the pictures on Amazon, but you should do you own research to confirm.

For example: (on program P7, I think)

-press start (Trigger)

-anneal for (T1,-0) 3.7 seconds (or whatever you program)

-delay for (T2,-1) 15 seconds to allow for case removal/replacement and help control component overheating (longer or shorter time depending on how hot you want your annealer to run)

-automatically start over (C-,00)

--------------------------------------------

Some EXAMPLES of components from Amazon

Large power supply

Small power supply

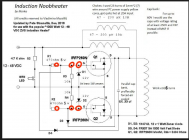

ZVS Board

Timer module

Large DPDT relay

Coolant Pump/Reservoir

About $175 total plus any switches, copper tubing, wire, etc you might need...