You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Induction brass annealer redux

- Thread starter Gina1

- Start date

It could be the camera angle or how the video was made but to my eyes and looks like some of the cases clearly glowed red and other ones didn't.Doing some .223 with it.

No, it’s not an AMP or at all as sophisticated as the kind of build in this thread. But it works well, works fast, is super easy to make, and is only about $200.

I had to try for myself, it was so compelling. And it work well enough for me that I’m not looking to upgrade.

Your eyes aren’t fooling you. You’re correct. Cases will vary in electrical resistance and some will definitely respond differently to the same or similar inputs.It could be the camera angle or how the video was made but to my eyes and looks like some of the cases clearly glowed red and other ones didn't.

But that kind of shows one of the virtues of induction annealing that makes it so forgiving. There’s a wide range of temperatures between minimum anneal and nearly melted that will give a satisfactory anneal.

You must remember that the commonly quoted temperature of 600F for annealing brass takes an hour and produces a scrapped case after an hour. We’re after a “flash anneal” where we anneal hot enough to do it in a second or so. That means we’re looking for temperature closer to 1050-1100F. Hotter is ok, we just have to hit that temperature. The downside to going hotter is we carry the hardness gradient slightly farther down the case.

But because we’re controlling time to 0.01 seconds, the total energy put into the brass is pretty consistent, with variation coming from the case itself and things like the position of the coil on the case.

Because I was filming, I was holding the coil with only one hand and positioning was less consistent than normal use.

As you can see at the end of the clip, we achieve the goal of annealed neck and shoulders, with a notable transition just below the case shoulders. This transition location is consistent with what I see in clips of AMP cases and on the factory annealed brass I have from Lapua and others.

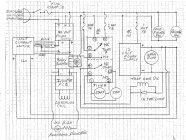

Still cant see the the attached GE Induction Annealer Rev 2 schematic in post 2188.Sorry about that. I don't know how it happened. Last month they did an up load/reload of the system. Guess they reduced large files.

If you need more information, please feel free to write.

Gina1

Please repost. Many thanks.

It is not there. May have been deleted or removed due to size. Try sending a PM to OP and they may be able to send it to you directly.Still cant see the the attached GE Induction Annealer Rev 2 schematic in post 2188.

Please repost. Many thanks.

Thanks, Gina.NOTE That this design is almost 6 years old. There have been numerous upgrades and improvements. This is just the basic start. One example is replacing the 110 volt AC fans with 12 volt DC fans. reading the thread will give you many ideas.

Good luck on your build

Gina

A loooong thread with posts from novices and EE level experimenters with lots of refinements, many contradicting each other and adding confusion to those at hobbyist level understanding of electronics, myself included.

What I was hoping for was an updated version of the schematics embodying the best of the tried and tested refinements with the following objectives:

Cheapest build with robust and durable build;

Revisiting the best contactor specs for the job - SSC or fiddling with the mosfets to ground;

Achieving the objective of annealing a variety of cases to the proper temps with short heating time;

Possible use of a C type ferrite inductor combined with a Litz wire coil in a sheath (with additional fans and without cooling) for the work coil;

Modularising the water cooling, case feeder, trap door automation so that builders can opt for it at start, or upgrade as their needs, funding or itches dictate.

This will probably simplify and clarify the best options with a few alternatives provided here and there.

My thanks for your prompt and comprehensive answers along the thread.

Regards,

Linga

It has developed from a simplified unit to some very advanced fully auto machines with some very professional programing.

Reading, learning and following the progress from the start really helps to understand the workings of the unit and the point to which you would like produce your own machine to.

Itchytf has the best idea start at the beginning choose what your after then start the build and ask questions along the way. There is no right way to achieve the same outcome in many instances.

Reading, learning and following the progress from the start really helps to understand the workings of the unit and the point to which you would like produce your own machine to.

Itchytf has the best idea start at the beginning choose what your after then start the build and ask questions along the way. There is no right way to achieve the same outcome in many instances.

I spent a bit of time recently winding and testing a few different coils for my machine. I've been using a double wound coil because it works better for me with the way my machine is designed, 6BR cases particulary work a lot better because they were sitting pretty low in a single wound coil. I'm a very trial and error type of person and was amazed at the difference between the ones I tried.

The current coil is around 17mm ID, I slid the basalt sleeve onto the copper tube before I wound it then wound the inner coil, wrapped a piece of thin plastic around it to give some clearance and wrapped the outer coil directly onto that.

The previous coil was 28mm ID and took around 4 seconds for a 223 case. This one melted the neck of the case at 2 seconds to begin with. I dialed the voltage back to 32v from 48v and it's running them through at 2.3 seconds. I've run lots of 200 cases through it without any overheating issues so it's not working too hard. I don't currently have an amp gauge on it so not sure what current it's drawing but I'm guessing not over the top.

The current coil is around 17mm ID, I slid the basalt sleeve onto the copper tube before I wound it then wound the inner coil, wrapped a piece of thin plastic around it to give some clearance and wrapped the outer coil directly onto that.

The previous coil was 28mm ID and took around 4 seconds for a 223 case. This one melted the neck of the case at 2 seconds to begin with. I dialed the voltage back to 32v from 48v and it's running them through at 2.3 seconds. I've run lots of 200 cases through it without any overheating issues so it's not working too hard. I don't currently have an amp gauge on it so not sure what current it's drawing but I'm guessing not over the top.

Current is totally irrelevant, as long as the PS is not overloaded. Nice built. 6mm BR are very vulnerable to over heating (voltage fluctuation etc) . IMO if you can increase the 2.3 sec you would be more in control. That is what I'm planning to do with my latest built, or continue with 6 mm Dasher.

ST42

Silver $$ Contributor

Hi Gents,

I am Very close to completing my build. I elected to use the MGNZ Arduino Uno controller. I wanted to be able to use the this system to easily enable the hopper feed.

Unfortunately I am having a problem, and for the life of me, I cannot figure it out. So I am turning to you all for some ideas.

My problem is this,

My annealer runs perfectly, until I place a piece of brass into the coil, Then the annealing process stops. I get an error message say that there is a coil fault. (I should tell you all that Mark, the seller of the MGNZ board has been helping me trouble shoot this, but since he is one day ahead of me. It takes a bit of time to get emails replied to. He has definitely been there for product support.)

Here is some information / attempted solutions that I have used.

1. Running 48v 600 watt power supply

2. I’ve replaced / swapped out two ZVS boards and Two Relays.

3. The coil is not touching itself in the windings. I used insulation on it.

4. I’m drawing 9.8 A while the annealer is running and this is with No brass in the coil.

5. If I attemp a 2 sec. run of the annealer using LC 5.56 brass, it will anneal for approximately .2 seconds and then display a fault. Time length of annealing has no difference in outcome.

6. If I run the annealer without brass, for any amount of time, it cycles normally. If I introduce an object into the running annealer, say a Long bladed screw driver. The annealer will immediately stop annealing, and display the Coil Fault message. Also the screw driver never came into contact with the coil. The screw driver remains at room temp.

7. The coil is cooled, and I can see the temp rise as it anneals. After it anneals, the temp drops back down with the coolant being cycled through the radiator.

I am Not a tech guy. I have zero knowledge of most things that use circuits or electricity. If any of you fellows might have any ideas as to trying to solve my issue. I would greatly appreciate your help.

Thanks,

ST42

I am Very close to completing my build. I elected to use the MGNZ Arduino Uno controller. I wanted to be able to use the this system to easily enable the hopper feed.

Unfortunately I am having a problem, and for the life of me, I cannot figure it out. So I am turning to you all for some ideas.

My problem is this,

My annealer runs perfectly, until I place a piece of brass into the coil, Then the annealing process stops. I get an error message say that there is a coil fault. (I should tell you all that Mark, the seller of the MGNZ board has been helping me trouble shoot this, but since he is one day ahead of me. It takes a bit of time to get emails replied to. He has definitely been there for product support.)

Here is some information / attempted solutions that I have used.

1. Running 48v 600 watt power supply

2. I’ve replaced / swapped out two ZVS boards and Two Relays.

3. The coil is not touching itself in the windings. I used insulation on it.

4. I’m drawing 9.8 A while the annealer is running and this is with No brass in the coil.

5. If I attemp a 2 sec. run of the annealer using LC 5.56 brass, it will anneal for approximately .2 seconds and then display a fault. Time length of annealing has no difference in outcome.

6. If I run the annealer without brass, for any amount of time, it cycles normally. If I introduce an object into the running annealer, say a Long bladed screw driver. The annealer will immediately stop annealing, and display the Coil Fault message. Also the screw driver never came into contact with the coil. The screw driver remains at room temp.

7. The coil is cooled, and I can see the temp rise as it anneals. After it anneals, the temp drops back down with the coolant being cycled through the radiator.

I am Not a tech guy. I have zero knowledge of most things that use circuits or electricity. If any of you fellows might have any ideas as to trying to solve my issue. I would greatly appreciate your help.

Thanks,

ST42

Similar threads

- Replies

- 74

- Views

- 47,372

- Replies

- 0

- Views

- 1,576

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.