You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Induction brass annealer redux

- Thread starter Gina1

- Start date

Thanks. I was hoping it was measured and so I could get a feel for how well the above calculator works for our application. It's a real b*tch for me to play with work coils in my build. As @itchyTF notes, if you had an oscilloscope it would be easy to measure. There's some benefit to me redoing my work coil to have it sit lower so there's more room for the flame sensor to look downwards and still allow me to use my feeder. Hence interest in the double-wound coil structure.Calculated.

I connect the scope probe tip to its ground lead and hold the loop near the coil. Not too close but enough to get a decent signal. Waveform looks decent and can get a good measurement.

You can simply probe across the terminals of the induction board directly (touching).

I don't have an oscilloscope, otherwise I would measure the value rather than calculate it. It sounds like I am using the same ZVS board that you are and I am happy to share my coil dimensions:Thanks. I was hoping it was measured and so I could get a feel for how well the above calculator works for our application. It's a real b*tch for me to play with work coils in my build. As @itchyTF notes, if you had an oscilloscope it would be easy to measure. There's some benefit to me redoing my work coil to have it sit lower so there's more room for the flame sensor to look downwards and still allow me to use my feeder. Hence interest in the double-wound coil structure.

You can simply probe across the terminals of the induction board directly (touching).

1/8" copper tube

Total turns: 6.5

Coil ID: 0.645"

Coil OD: 1.260"

Coil Length: 0.690"

It occur to me that if you use a simple step motor to swing the sensor over the coil during annealing time you could keep your mechanics intact. Just switch to Arduino control inside the nice looking box. Just a thought.There's some benefit to me redoing my work coil to have it sit lower so there's more room for the flame sensor to look downwards and still allow me to use my feeder.

P.S. Can somebody explain to me how the impedance (calculated or measured) of the coil and the ZVS board or the frequency practically affect the annealing process.

This article explains it very well:It occur to me that if you use a simple step motor to swing the sensor over the coil during annealing time you could keep your mechanics intact. Just switch to Arduino control inside the nice looking box. Just a thought.

P.S. Can somebody explain to me how the impedance (calculated or measured) of the coil and the ZVS board or the frequency practically affect the annealing process.

Effect of Increasingly High Frequency on Induction Heating

What is the effect of high frequency on induction heating? High frequency heating induction is type of a heating process that uses high frequency electricity to heat the substances that are conductive electrically in nature. This article describes the basics of induction heating, the frequency...

Here is my curiosity - How the coil impedance is selected to work with a "standard" induction board and what provisions are included, in the calculations, for a brass presence into the magnetic field?I am using the "standard" induction board with 1.98uF capacitance. My coil is 2 layer with 6.5 turns and calculated at 122 KHz

I don't think the work object affects the frequency of oscillation enough to matter too much. Way back here I posted oscilloscope screenshots of my annealer with and without a 308 case in the work coil.

Oscilloscope screen shots

The frequency just needs to be suitable for the application. As you know, there is a relationship between the inductance (of the work coil) and the capacitance of the tank oscillator that determines the frequency of oscillation. https://www.allaboutcircuits.com/tools/tank-circuit-resonance-calculator/ I think the original GinaErick work coil just happened to have an inductance that yielded a frequency more-or-less suitable for this process (circa 106kHz). In a little (and rather crude) demonstration listed by Ambrell on their website (there's a video of it as well) they use 113kHz (and mention a temperature of 1250F). How broad a range of frequency is suitable I have no idea, but if Ambrell demonstrate annealing cartridge brass at 113kHz I don't want to veer too far from it absent further information.

Ha. I should have enough room for the sensor to peak into the coil. If I get a shorter coil (less vertical length) with similar inductance it will make the job easier plus it should help concentrate the flux flow area. Reducing the diameter of the coil comes with an inductance cost. Unfortunately I sold all the excess 1/8" copper tubing I had. I've had to buy some more to play around.

Oscilloscope screen shots

The frequency just needs to be suitable for the application. As you know, there is a relationship between the inductance (of the work coil) and the capacitance of the tank oscillator that determines the frequency of oscillation. https://www.allaboutcircuits.com/tools/tank-circuit-resonance-calculator/ I think the original GinaErick work coil just happened to have an inductance that yielded a frequency more-or-less suitable for this process (circa 106kHz). In a little (and rather crude) demonstration listed by Ambrell on their website (there's a video of it as well) they use 113kHz (and mention a temperature of 1250F). How broad a range of frequency is suitable I have no idea, but if Ambrell demonstrate annealing cartridge brass at 113kHz I don't want to veer too far from it absent further information.

It occur to me that if you use a simple step motor to swing the sensor over the coil during annealing time you could keep your mechanics intact. Just switch to Arduino control inside the nice looking box. Just a thought.

Ha. I should have enough room for the sensor to peak into the coil. If I get a shorter coil (less vertical length) with similar inductance it will make the job easier plus it should help concentrate the flux flow area. Reducing the diameter of the coil comes with an inductance cost. Unfortunately I sold all the excess 1/8" copper tubing I had. I've had to buy some more to play around.

Last edited:

Creating a tank - coil inductance and board capacitanceThe frequency just needs to be suitable for the application. As you know, there is a relationship between the inductance (of the work coil) and the capacitance of the tank oscillator that determines the frequency of oscillation.

Correct me if I'm wrong

a) The task is to create a tank with a resonance frequency equal to the frequency of the board itself (~100 KHZ).

Or:

b) The task is to create a tank with resonance frequency equal to our own selection.

In addition, I noticed that the equipment temperature rise affects the annealing accuracy. The brass comes out slightly under-annealed. For now, I changed the algorithm - before every annealing cycle, the equipment temperature is measured and appropriate correction is applied.

Not quite. The task is to create an induction annealer operating at an appropriate frequency. The frequency of the 'board'/annealer (board and coil) resonance is determined by the capacitance on the board and coil inductance. Given the first is fixed we aim to design a coil with an appropriate inductance to achieve an appropriate frequency. (Of course we aren't super sure of what the appropriate frequency range is but have some indications from the likes of Ambrell.)

Which equipment? Proxy for temp of sensor?

Which equipment? Proxy for temp of sensor?

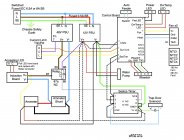

Thanks. I did not realize that our annealing coil inductance determines the frequency of the board. I had to see the schematic of the heating ZVSs to realize that.The frequency of the 'board'/annealer (board and coil) resonance is determined by the capacitance on the board and coil inductance.

Is there any consensus about an appropriate frequency for our brass and how to determine the capacitance of a commercial ZVS board?

Thanks again

For the first part of your question, it would seem circa 106kHz works based on the GinaErick design, 113kHz is ok according to Ambrell and even higher might be ok based on @VenatusDominus experience. Re the second part, I assume you mean the boards we've all purchased (the basic design of which is the schematic I've posted before). Here you can add up there nominal value of the capacitors on the board. It won't be absolutely perfect because these aren't high tolerance (eg +- 1%) caps but it will be good enough. The boards use six .33uF capacitors.

Presumably one could use the equation in the link provided by @VenatusDominus and the typical thickness of brass in a rifle cartridge to determine the upper limit of acceptable frequency (given we want to anneal the full thickness of the brass).

Hello Induction Brass Annealer Redux community! I'm stuck. I'll try to make this as simple as possible. I have read all 149 pages of this thread (seriously). I am humbled by the machines people are making, I am also very grateful everyone is taking the time to share.

I built a GinaErik (not to spec). I didn't follow the recipe because I didn't know the recipe when I started.

I have:

RSP-750-48

Ocestore 1000W ZVS Induction Heating Board

DROK DC 4.5-100V Digital Voltmeter Ammeter Multimeter Panel

Pemenol LCD Digital Timer Relay 12V 24V Controller Board

Self made coil 1/8 OD copper tube coil (1.125in ID) connected to 1/4 ID copper tube (soldered)

12 gauge stranded wire for the 48V power supply

12V 3amp DC power supply for peripherals

DC cooling fans

DC water pump with radiator

The main way my unit differs is the the timer relay (forget about the other thing I've done because I'm afraid I'll get flamed however it should bear no difference in this discussion). I am using a 12 volt power supply to switch the RSP-750 current on and off via a relay. I have tried a few different switches; TWTADE SSR-40 DD 40A solid state relay (didn't work), a manual switch rated for 120V 20amp AC power, and a Standard Ignition 70amp multi-purpose relay (12 volt, 70amp). Because this is a single pole switch I am not using a varistor (I know, I know....). This could be the source of my problem, please read on.

My machine currently works (sort of). It takes 11 seconds to produce enough heat in the brass for annealing (probably not truly annealed). If I select a longer time, the power supply trips (at 9.5 amps, resettable). The RSP-750 has the voltage selected to the lowest setting because anything higher than that voltage causes the power supply to trip sooner and the brass is no more annealed (I can get the amperage a bit higher 10.3 amps with an increase in voltage however the power supply trips sooner). It makes no difference if I use a manual switch or the Standard Ignition relay to the board, the power supply trips. I only have 700 degree Tempilaq, forget about that for a minute please, I purchased that before I was convinced I need to generate higher temps to get a good anneal.

What I have tried: different switching methods to the ZVS board, a new ZVS board, checking all connections on the board, ensuring the heat sinks aren’t shorted, configuring the RSP-750 to current limiting mode (I don’t think this worked since the power supply wouldn’t generate hardly any power), I have made multiple coils, expanded my coil, compressed my coil, ensuring my coil isn’t shorted, raising and lowering my brass within the coil, etc. My power supply is currently set to factory defaults (pins jumped according to the spec sheet).

I know I’m forgetting something I’ve tried and/or explaining my setup properly. There is no metal in or around the coil or the board (other than the brass). I have a video to demonstrate the operation and to show the build.

Thanks!

I built a GinaErik (not to spec). I didn't follow the recipe because I didn't know the recipe when I started.

I have:

RSP-750-48

Ocestore 1000W ZVS Induction Heating Board

DROK DC 4.5-100V Digital Voltmeter Ammeter Multimeter Panel

Pemenol LCD Digital Timer Relay 12V 24V Controller Board

Self made coil 1/8 OD copper tube coil (1.125in ID) connected to 1/4 ID copper tube (soldered)

12 gauge stranded wire for the 48V power supply

12V 3amp DC power supply for peripherals

DC cooling fans

DC water pump with radiator

The main way my unit differs is the the timer relay (forget about the other thing I've done because I'm afraid I'll get flamed however it should bear no difference in this discussion). I am using a 12 volt power supply to switch the RSP-750 current on and off via a relay. I have tried a few different switches; TWTADE SSR-40 DD 40A solid state relay (didn't work), a manual switch rated for 120V 20amp AC power, and a Standard Ignition 70amp multi-purpose relay (12 volt, 70amp). Because this is a single pole switch I am not using a varistor (I know, I know....). This could be the source of my problem, please read on.

My machine currently works (sort of). It takes 11 seconds to produce enough heat in the brass for annealing (probably not truly annealed). If I select a longer time, the power supply trips (at 9.5 amps, resettable). The RSP-750 has the voltage selected to the lowest setting because anything higher than that voltage causes the power supply to trip sooner and the brass is no more annealed (I can get the amperage a bit higher 10.3 amps with an increase in voltage however the power supply trips sooner). It makes no difference if I use a manual switch or the Standard Ignition relay to the board, the power supply trips. I only have 700 degree Tempilaq, forget about that for a minute please, I purchased that before I was convinced I need to generate higher temps to get a good anneal.

What I have tried: different switching methods to the ZVS board, a new ZVS board, checking all connections on the board, ensuring the heat sinks aren’t shorted, configuring the RSP-750 to current limiting mode (I don’t think this worked since the power supply wouldn’t generate hardly any power), I have made multiple coils, expanded my coil, compressed my coil, ensuring my coil isn’t shorted, raising and lowering my brass within the coil, etc. My power supply is currently set to factory defaults (pins jumped according to the spec sheet).

I know I’m forgetting something I’ve tried and/or explaining my setup properly. There is no metal in or around the coil or the board (other than the brass). I have a video to demonstrate the operation and to show the build.

Thanks!

I am using a 12 volt power supply to switch the RSP-750 current on and off via a relay. I have tried a few different switches; TWTADE SSR-40 DD 40A solid state relay (didn't work), a manual switch rated for 120V 20amp AC power, and a Standard Ignition 70amp multi-purpose relay (12 volt, 70amp). Because this is a single pole switch I am not using a varistor (I know, I know....). This could be the source of my problem, please read on.

You shouldn't be having issues with the relay. You don't need a varistor using 12V and a relay.

The RSP-750 has the voltage selected to the lowest setting because anything higher than that voltage causes the power supply to trip sooner

What do you mean by "the power supply to trip"? The RSP-750 has internal current limiter protection. It should work fine with 48V and 15.7A.

That's the problem, the power supply trips (internal current limit protects) well before 15.7amps. So maybe I have a power supply issue.You shouldn't be having issues with the relay. You don't need a varistor using 12V and a relay.

What do you mean by "the power supply to trip"? The RSP-750 has internal current limiter protection. It should work fine with 48V and 15.7A.

Okay, great idea! ....It didn't work. At 43 volts the power supply cut out (internal current limit protect) around 8 seconds. At 48 volts it cut out around 1 second. The brass didn't heat up any more than it did with the shunt in place.Remove the amp meter for starters just to eliminate that

(Nice idea to spin the case)

But it looks like the power goes off completely (judging from your ammeter display) rather than merely limiting. Your ammeter should be powered from the 12V supply.

Similar threads

- Replies

- 74

- Views

- 47,354

- Replies

- 0

- Views

- 1,574

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.