I use coolant and have a five gallon plastic bucket as a reservoir with about 3 gallons of coolant mix in it. Since I use this for flood coolant for most of my machine work, I lose a bit to the environment, so I have to top off every so often.For those that have one up and running, how much oil/coolant or whatever product you’re using, what is the capacity of your system? 1 gallon, 5 gallon, 10 gallon?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chamber flush system build log.

- Thread starter LVLAaron

- Start date

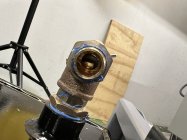

Yes, I purchased it from MSC--not the least expensive place around but close to home and very fast shipping to me usually:@Henryrifle you got a part number or link for that pressure regulator?

@WillyTP - My tank is 3 gal. Way more than needed.

Hank

BuffaloBill

Silver $$ Contributor

I use 5gal of Rigid Extreme.

Mine is 5 gal.

How do you like the Rigid Extreme? I went with the Swiss stuff but have 10 one gallon jugs Rigid stuff on the shelf. Might have to try it or sell it. Tired of looking at it.I use 5gal of Rigid Extreme.

BuffaloBill

Silver $$ Contributor

It seems to flow adequately at 40psi (shop temperature is generally no cooler than 65F) and doesn’t smell too badly. I’ve been thinking about thinning it with a bit of ATF as others have mentioned. It’s the only fluid I’ve used since building the flush system, so certainly can’t claim it’s better than other options.Mine is 5 gal.

How do you like the Rigid Extreme? I went with the Swiss stuff but have 10 one gallon jugs Rigid stuff on the shelf. Might have to try it or sell it. Tired of looking at it.

My understanding is that sulfur in older(?) threading oil can darken machined surfaces like lathe ways. I was hoping to avoid staining by picking a fluid not containing high sulfur content. Since then I read where experienced people stated that modern oils are not likely to contain sulfur anyway.

Before using the flush system for the fist time, I had envisioned the fluid ending up all over me and the lathe. But in practice, especially having the foot switch to turn the pump on/off, the pressure relief valve, and the beverage bottle around the reamer, it really isn’t messy at all.

LVLAaron

Gold $$ Contributor

For anyone reading this in the future, I tired an inexpensive 1/8 HP immersible coolant pump, a very expensive 1/4 HP immersible coolant pump and finally the Procon carbonator pump attached to a 1/3 HP motor.

I thought the plumbing might be difficult but followed the advice of X Count in post #429 and ended up with a system that can easily flush chips through the chamber regardless of what chamber is being cut with readily adjustable pressure.

I am using Astro Swiss oil suggested by LVLAaron and Dave Tooley and couldn't be happier with that lubricant. It cuts a great chamber, doesn't stink even when you have an accident...tell you later.

If you start with that pump/motor combo you'll end up with a system capable of doing what you want to do the first time and it is actually less expensive than the larger immersible pump.

While chambering with the 1/8 or 1/4 HP immersible pump is still much faster than removing the reamer every .030 or .050, cleaning and relubricating, it's just easier to have the option of turning up the pressure to whatever you need with the Procon.

One word of caution. If you forget to turn the air valve off once you've finished blowing out the barrel/chanber, it will rain oil in your shop and leave a permanent reminder on your ceiling...No matter how fast you can turn it off.

This has been and continues to be a great thread and I am very thankful to all who contributed their knowledge and experience to it.

Hank

I thought the plumbing might be difficult but followed the advice of X Count in post #429 and ended up with a system that can easily flush chips through the chamber regardless of what chamber is being cut with readily adjustable pressure.

I am using Astro Swiss oil suggested by LVLAaron and Dave Tooley and couldn't be happier with that lubricant. It cuts a great chamber, doesn't stink even when you have an accident...tell you later.

If you start with that pump/motor combo you'll end up with a system capable of doing what you want to do the first time and it is actually less expensive than the larger immersible pump.

While chambering with the 1/8 or 1/4 HP immersible pump is still much faster than removing the reamer every .030 or .050, cleaning and relubricating, it's just easier to have the option of turning up the pressure to whatever you need with the Procon.

One word of caution. If you forget to turn the air valve off once you've finished blowing out the barrel/chanber, it will rain oil in your shop and leave a permanent reminder on your ceiling...No matter how fast you can turn it off.

This has been and continues to be a great thread and I am very thankful to all who contributed their knowledge and experience to it.

Hank

I've got a few barrels under my belt with my new flush system. Very happy with the result using the high pressure and Astro Swiss. I have a few changes to make it more user friendly now that I see what was more clumsy to operate. First of which was proper splash cup. Used a big mouth water bottle and made a sleeve that pressed in and then slide over the the JGS reamer holder with a nylon tip set screw. I need to move the valves, gages and pump switch to the side closest to me when at the lathe. I ended up liking the cart rotated 180 degrees from where planned so the return hose flows best into the tank better. But I could not be more happy with the results!

Attachments

Nice and clear and easy to see the reamer.

I ended up getting a piece of Perspex 3" tube and making an acetal disk that fits over the od of the reamer holder and has o rings on the outside of the disk to match the ID of the Perspex tube. That allows me to slide the Perspex tube on the O rings to give the correct reamer coverage and also push it rite back,or take it off, when cleaning or adjusting the reamer stop

I ended up getting a piece of Perspex 3" tube and making an acetal disk that fits over the od of the reamer holder and has o rings on the outside of the disk to match the ID of the Perspex tube. That allows me to slide the Perspex tube on the O rings to give the correct reamer coverage and also push it rite back,or take it off, when cleaning or adjusting the reamer stop

LVLAaron

Gold $$ Contributor

I just ordered Buna-N rubber tubing to replace all my oil lines.

That plastic crap isn't compatible with petroleum products, gets hard/stiff and brittle.

I replaced all of mine as well. I used the cheap "RV Water line" stuff once I had the design finished. That stuff only lasts for 5 years when you use water... not sure what it's life is with oil

Up to about 40psi and when stopping can use air to push anything outI'm not running the pressure high enough to need a shield / cup of any sort. Where about are you guys running?

LVLAaron

Gold $$ Contributor

Up to about 40psi and when stopping can use air to push anything out

Roger. I'm about half that. Too scared to blow my dongle off the muzzle end of the barrel. I'll turn up the next one and wrap a diaper around the attachment

I'm running 80 psi but don't have to worry about a blow out with the muzzle adapter set up. I turn the the volume valve to a smaller flow amount on retracting before the bushing exits the bore. The hose I used was petroleum rated but we'll see how it does. Wish it was more flexible even when new though.

Attachments

ridgeway

Silver $$ Contributor

Funny thing is...he used to sell his muzzle flush cup with clear reinforced plastic line that hardens in a day if it contacts petroleum products.Greg Tannel says to use hydraulic hose. There are loads of good options out there, so it's puzzling why we all seem to start with hose that gets hard after a year.

Similar threads

- Replies

- 1

- Views

- 1,187

- Replies

- 37

- Views

- 8,443

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.