For calibers you are dedicated to, it is good to own at least the Go-Gage.

With the gage and some tape on the base, you can get a pretty good measure of your rifle's headspace dimension to within the thickness of the tape steps.

Gages are more rigid than brass cases, so you get a pretty good answer without necessarily stripping the bolt, but you can if you want to.

Then, you can use that gage w/tape to reference your Hornady tools to see how virgin or cycled brass compares and to get a much clearer picture of how much you are really bumping.

This doesn't answer all the questions in this thread, but it takes the lengths of the shoulder bump off the table. That still leaves us with diameters and the brass, but at least the bump question is eliminated.

I was surprised that more folks who reload don't own the Go-Gage for their favorite cartridges. They are certainly used by gunsmiths, but have as many uses for reloaders as they do for setting up chambers.

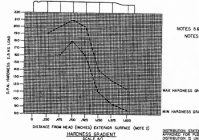

Now for the question of what is causing the OP's issues... If the shoulder bump is taken off the table, and there isn't a huge difference between the chamber diameters and the sizing die, then it would be time to do a fine survey of the brass hardness values, with an emphasis right near the break.

A few samples of virgin, a few samples of brass with two cycles, and a few samples of ones that are either broken or ready to break, and we would have the answers. Here is an example of the values for "normal" mil-spec 556 brass hardness values.

View attachment 1424188