It's likely being caused by less than perfect brass IMO. 4 firings isn't much for 223 brass.

I've recently found a few pieces of my Lapua 223 brass with faint "rings" around the cases in a similar position as the OPS.

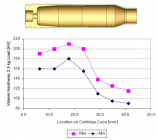

When I sectioned them, this is what I found..

Interestingly, the "ring" on the outside wasn't always exactly opposite the thinned area on the inside. Offset maybe 1/8" to 1/4".

The cases were 18 times fired in a Tikka T3x Varmint, completely original. Not annealed, sized with a Lee Pacesetter FL die, and more recently with a Forster FL Benchrest series die.

They get cleaned in an ultrasonic cleaner, which is why the inside is so clean. The axial scratches are from a dental pick, feeling for a thin spot before they were cut.

They developed donuts on the inside of the neck from the thicker shoulder material being pushed forward over their life. That was reamed out and they carried on.

Probably trimmed to length 4 to 5 times over 18 firings. The primer pockets aren't what I'd call tight any more, but they show no signs of leakage, definitely not loose by my standards.

Loads were moderate, mostly about 23 grains of Vihtavuori N140 under a 75 to 80 grain bullet. Call it 2750 fps out of a 24 inch barrel.

Using the Hornady comparator (.330 bushing) I am sizing them to 1.458"-1.459". They don't get bumped every time, only when the shoulder gets far enough ahead to touch the die. Cases that are fresh out of the rifle measure from 1.458" to 1.460". I know from experience that 1.461" is tight chambering.

Virgin Lapua brass measures about 1.456" with my tools.

They're not being overworked length-wise, and as has been said, accurately measuring a tapered wall case diameter is tricky business. The Tikka supposedly has a CIP or SAAMI spec chamber, how tight that is around the diameter is a good question.

My policy is that as soon as I see a ring starting around the body, they go in the scrap metal bucket. I don't need case separations, and 18 firings is pretty respectable.

The reason I say that the brass is "less than perfect" is that I had an 8x fired PMC case develop a slightly dark ring in the same area. When I flexed it in my fingers it broke apart. I doubt PMC is up to the same standard as Lapua or any premium brass maker, so it wasn't unexpected.

I don't have any personal experience with Starline brass, and I've stopped using PMC since I got the Lapua.

I do use Federal brass that I think is actually Lake City (range salvage) but can't say for sure. Both the Lapua and the Federal have been good.