Thank you for posting these images!

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

22 LR Bullet Sorting

- Thread starter Nick Caprinolo

- Start date

Hello.

The world is small. Article # 10

AMMO Comparison (benchrest.com)

The muppets hold up the mirror to me. Maybe I can see an idiot there.

No matter.

Thanks for thinking along.

Bohemian Rhapsody | Muppet Music Video | The Muppets - YouTube

The world is small. Article # 10

AMMO Comparison (benchrest.com)

The muppets hold up the mirror to me. Maybe I can see an idiot there.

No matter.

Thanks for thinking along.

Bohemian Rhapsody | Muppet Music Video | The Muppets - YouTube

The Stowaway,

I am easily confused, and I find myself there again looking at your most recent post.

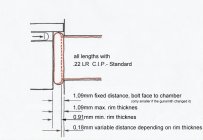

It is my observation that a thick rim or thin rim makes a difference only in how far the round is pushed into the chamber. (i.e. overall round length)

When loading a round the bolt face/locking lugs cams the round into the chamber when closing the bolt. That leaves the cartridge head against the bolt face. Regardless if the case head is thick or thin.

The only way there could be a gap as shown in your drawing would be if one pushed the round all the way in the chamber by a means other than closing the bolt.

What am I missing here?

Thanks you so much for your post. I along with many others find them extremely interesting.

TKH

I am easily confused, and I find myself there again looking at your most recent post.

It is my observation that a thick rim or thin rim makes a difference only in how far the round is pushed into the chamber. (i.e. overall round length)

When loading a round the bolt face/locking lugs cams the round into the chamber when closing the bolt. That leaves the cartridge head against the bolt face. Regardless if the case head is thick or thin.

The only way there could be a gap as shown in your drawing would be if one pushed the round all the way in the chamber by a means other than closing the bolt.

What am I missing here?

Thanks you so much for your post. I along with many others find them extremely interesting.

TKH

For the first time in a long time I find myself in agreement with both of you guys.

holstil, years ago I spent a lot of time and money experimenting with headspace. I had three Time Precision rifles which I could adjust the headspace by using spacers between the action face and barrel shoulder. My take away was headspace makes little difference if it is larger than the rim thickness on all the rounds you fire.

But having it too tight can destroy accuracy. If you can feel it when you close the bolt on even a few rounds it is too tight.

Years ago .042 was the most common headspace, then many went to .043, and now some including me are using .044. I think our ammo has changed over the years.

"Bolts don't cam like a screw till the bolt face hits the brass or barrel."

Lord help me if my bolt face hits the barrel. If that happens I screwed up more than usual.

Stowaway,

Your illustrations are excellent and clearly show how each round even from the same lot number can vary.

When one sets up a chamber and desires a certain amount engraving, one has to find a comfortable average. The "match" ammo we shoot just isn't all that precise.

TKH

holstil, years ago I spent a lot of time and money experimenting with headspace. I had three Time Precision rifles which I could adjust the headspace by using spacers between the action face and barrel shoulder. My take away was headspace makes little difference if it is larger than the rim thickness on all the rounds you fire.

But having it too tight can destroy accuracy. If you can feel it when you close the bolt on even a few rounds it is too tight.

Years ago .042 was the most common headspace, then many went to .043, and now some including me are using .044. I think our ammo has changed over the years.

"Bolts don't cam like a screw till the bolt face hits the brass or barrel."

Lord help me if my bolt face hits the barrel. If that happens I screwed up more than usual.

Stowaway,

Your illustrations are excellent and clearly show how each round even from the same lot number can vary.

When one sets up a chamber and desires a certain amount engraving, one has to find a comfortable average. The "match" ammo we shoot just isn't all that precise.

TKH

holstil

Silver $$ Contributor

Tony, you clearly have more experience and knowledge than me in this. I thought I saw a potential miss understanding and I thought I could shed light for anyone else reading with less than my experience. Please disregard.

Thanks for your insight. I will apply what I learned from you.

Thanks, Jim.

Thanks for your insight. I will apply what I learned from you.

Thanks, Jim.

Jim,

We are in agreement. My point was if the bolt nose does hit the barrel face it is too tight. There should always be clearance. The counter bore in the bolt nose ensures the head of the case is surrounded but should not be deep enough to allow the bolt nose to hit the barrel.

We are in agreement. My point was if the bolt nose does hit the barrel face it is too tight. There should always be clearance. The counter bore in the bolt nose ensures the head of the case is surrounded but should not be deep enough to allow the bolt nose to hit the barrel.

linekin

Silver $$ Contributor

I shoot for .003 between the bolt nose & barrel tenon. I also set for .044 headspace.Jim,

We are in agreement. My point was if the bolt nose does hit the barrel face it is too tight. There should always be clearance. The counter bore in the bolt nose ensures the head of the case is surrounded but should not be deep enough to allow the bolt nose to hit the barrel.

Question? What happens if the is a .002-.003 gap between the bolt nose recess & the rim as shown in the picture? Or with Eley having thinner rims, vice versa. A .001-.002 gap between the inside of the rim & the breech face? in What would that do to accuracy?

Keith

Keith,

Great question. Look at the illustration and think when the bolt cams closed and the front of the cartridge rim isn't against the barrel face.

When the firing pin strikes the case does it drive the round forward? If it does, since the pin only strikes one point on the case does that cause misalign of the bullet?

Would full engraving vs on the partial engraving have an affect on this?

For me these are unresolved questions.

The best I can tell from experience is that taking out that clearance results in much worse accuracy.

It has to be there but in what amounts are ideal/best, I still don't know.

TKH

Great question. Look at the illustration and think when the bolt cams closed and the front of the cartridge rim isn't against the barrel face.

When the firing pin strikes the case does it drive the round forward? If it does, since the pin only strikes one point on the case does that cause misalign of the bullet?

Would full engraving vs on the partial engraving have an affect on this?

For me these are unresolved questions.

The best I can tell from experience is that taking out that clearance results in much worse accuracy.

It has to be there but in what amounts are ideal/best, I still don't know.

TKH

Hi there,

actually we leave the opening topic ("bullet sorting")

However, these things are also interesting to think about.

I could imagine that the firing pin pushes the case forward a little. Hm?

As soon as the primer and propelant builds up the pressure, the case is pushed back against the bolt.

I don't think (I don't know) that there is a misalignment of the bullet. The chamber is not much bigger than the case.

A little back to the opening topic:

All important match shooters I know do ammunition tests first and decide on the best lot.

I don't know anyone who was really happy with measuring Rim or anything else.

The Stowaway

actually we leave the opening topic ("bullet sorting")

However, these things are also interesting to think about.

I could imagine that the firing pin pushes the case forward a little. Hm?

As soon as the primer and propelant builds up the pressure, the case is pushed back against the bolt.

I don't think (I don't know) that there is a misalignment of the bullet. The chamber is not much bigger than the case.

A little back to the opening topic:

All important match shooters I know do ammunition tests first and decide on the best lot.

I don't know anyone who was really happy with measuring Rim or anything else.

The Stowaway

Stowaway,Hi there,

actually we leave the opening topic ("bullet sorting")

However, these things are also interesting to think about.

I could imagine that the firing pin pushes the case forward a little. Hm?

As soon as the primer and propelant builds up the pressure, the case is pushed back against the bolt.

I don't think (I don't know) that there is a misalignment of the bullet. The chamber is not much bigger than the case.

A little back to the opening topic:

All important match shooters I know do ammunition tests first and decide on the best lot.

I don't know anyone who was really happy with measuring Rim or anything else.

The Stowaway

You speak the truth as ugly as it is, and yet we continue our quest for rimfire accuracy.

Nothing wrong with sorting, but may not be the most productive activity.

If it makes the shooter more confidant then it is worthwhile. If you think it will yield perfect ammo you may be disappointed.

TKH

Last edited:

Tony.. i myself feels that sorting does not make good ammo more accurate.. but i do feel that it makes the fliers more consistentStowaway,

You speak the truth as ugly as it is, and yet we continue our quest for rimfire accuracy.

Nothing wrong with sorting, but may not be the most productive activity.

If it makes the shooter more confidant then it is worthwhile. If you think it will yield perfect ammo you may be disappointed.

TKH

dellet

Gold $$ Contributor

Some of us that find value in sorting aren’t able to buy quality ammo. I have a couple of 22 shorts that I really enjoy shooting. Choices often seem to be between rejects and culls.

Sorting by rim thickness, rim to ogive and weight, does shrink groups by eliminating fliers. It’s a bit of quality control that just does not really happen at the factory.

It’s very interesting to see the videos posted by Stowaway, it might actually be faster and more beneficial to set up a jig and check runout in a couple places.

It’s also interesting to see what is taken for granted, when match quality is available on the shelf and all you have to do is find a lot that works. I’ve done that too.

Sorting by rim thickness, rim to ogive and weight, does shrink groups by eliminating fliers. It’s a bit of quality control that just does not really happen at the factory.

It’s very interesting to see the videos posted by Stowaway, it might actually be faster and more beneficial to set up a jig and check runout in a couple places.

It’s also interesting to see what is taken for granted, when match quality is available on the shelf and all you have to do is find a lot that works. I’ve done that too.

Holy Crap Batman!!! What an awesome thread! Extremely informative.

+1

Keith,

Great question. Look at the illustration and think when the bolt cams closed and the front of the cartridge rim isn't against the barrel face.

When the firing pin strikes the case does it drive the round forward? If it does, since the pin only strikes one point on the case does that cause misalign of the bullet?

Would full engraving vs on the partial engraving have an affect on this?

For me these are unresolved questions.

The best I can tell from experience is that taking out that clearance results in much worse accuracy.

It has to be there but in what amounts are ideal/best, I still don't know.

TKH

Well, I must confess, I told a white lie. I asked a question and said it was unresolved.

I expected someone would come back and say it is not unresolved, of course the amount of engraving

has an effect on how far the firing pin could/would drive the round out of alignment. But to my surprise no one did.

So let me say it now "more engraving is better than less, or no engraving". Matter of fact no engraving is just plain wrong. Makes for an easy bolt opening/closing but can't make consistent accuracy.

I know many have different opinions and that is OK, but am confidant in what I'm saying.

As always, I am willing to hear and learn from any information that proves, or suggests I am wrong.

TKH

Last edited:

All of the discussion in this thread got me curious; as I said early on, I had verified that sorting by rim thickness does help reduce group size with cheap bulk ammo, but once you got into match grade ammo, don't waste your time, just find the brand and lot the particular rifle likes and go for it. My standard example for rim thickness sorting benefits is the dreaded Remington Thunderbolt, which has a huge variation in rim thickness in a box of 500 - from less than 0.035 to the desired few out of 500 over 0.040. USMCDOC's comment with regard to sorting the cheap stuff making the flyers more consistent is not that far off, lol. My sorting groups were 0.036 and less (the fouler group) over 0.036 to 0.038, over 0.038 to less than 0.040 and 0.040 up. As you went up, the groups size for multiple 5 shot groups went down, and the group size for the the few in the 0.040 and over group was actually quite decent, compared to the rest, but the rim thickness variation in 500 was considerable, none the less. And 5, 5 shot groups about used up the 0.040 and over group. As you went up in thickness, the population of each group went down after you ruled out the fouler group - the over 0.036 to 0.038 group was by far the largest, with marginally acceptable accuracy.

That got me to wondering about HV bulk ammo, so I grabbed a 525 round box of Remington Golden Bullets (bought on sale at Dick's Sporting Goods at least 3 years before their AR15 debacle turned me off on them, so this is not current manufacture stuff) and grabbed my case rim sorting tool, a dial indicator snap gauge that makes fast sorting easy, and set to work. An hour and 10 minutes later, we had gone through all 525, and compared to Thunderbolt, the results were shocking. They ended up being put into two groups - less than 0.040, and 0.040 and over. Slightly more than half were in the thicker group, a few going as high as 0.043. In the thinner group, there were only 5 very slightly thinner than 0.038. The next time we have a "warm" day (high 45 degrees, lol), we'll set up the bench and see if there is any difference in the grouping ability between the two lots, firing them out of two or three different rifles of known consistency. I have no idea about how much rim thickness in bulk Remington HV stuff will effect how it shoots, but both the thickness of the rims and the relative consistency of thickness from cartridge to cartridge compared to Thunderbolt caught me completely and pleasantly by surprise. We'll report back when we get a chance to shoot it.

That got me to wondering about HV bulk ammo, so I grabbed a 525 round box of Remington Golden Bullets (bought on sale at Dick's Sporting Goods at least 3 years before their AR15 debacle turned me off on them, so this is not current manufacture stuff) and grabbed my case rim sorting tool, a dial indicator snap gauge that makes fast sorting easy, and set to work. An hour and 10 minutes later, we had gone through all 525, and compared to Thunderbolt, the results were shocking. They ended up being put into two groups - less than 0.040, and 0.040 and over. Slightly more than half were in the thicker group, a few going as high as 0.043. In the thinner group, there were only 5 very slightly thinner than 0.038. The next time we have a "warm" day (high 45 degrees, lol), we'll set up the bench and see if there is any difference in the grouping ability between the two lots, firing them out of two or three different rifles of known consistency. I have no idea about how much rim thickness in bulk Remington HV stuff will effect how it shoots, but both the thickness of the rims and the relative consistency of thickness from cartridge to cartridge compared to Thunderbolt caught me completely and pleasantly by surprise. We'll report back when we get a chance to shoot it.

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.