Y'all are a little (lot) out of my league,and this might not translate well but here goes.

I shoot cast out of some pretty nice factory rifles. These aren't your Gdad's cast loads though. They are high velocity,in the realm of starting book jacketed loads. For instance,have been shooting a mint '80 R700V 6mmR this past week in the 2800fps range,into .2's and 3's 100 yard groups off admittedly,pretty cheesy X bags,even though we have a very nice full on BR setup. Too lazy to drag it out.

Stay with me.

Won't go into the long,and honestly dry,complete breakdown of loading specs/processes because they don't apply to rimfire although,some might if you're breaking down ammo.

I shoot bore ride bullets which,if you were to listen to the experts,should not be as accurate as non. These bullets interestingly are "knurled" and roll sized vs conventional,push through. There's a cpl reasons for this again,getting off my point. One of the very last ops on this ammo,right before cleaning the loaded round and putting it into it's ammo box is;

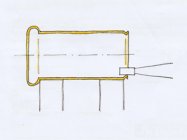

I call it an LG for little goober. It's a small length of O1 drill rod. 3/4" diameter,about an inch long. It gets chucked up in a lathe and drilled/reamed to be used as a hand held nose forming die. The depth of engagement.... and this is being done to the finished,assembled round.... is dependent on testing.

A single taper interior allows,usually,one trip on the lathe reaming because of the inherent nature of a taper. Run the bullet in to where testing/groups shows results. On a two angle taper,where you're gonna also hit the first drive band.... will see the LG making another trip or two on the reaming to find the sweet spot.

I can easily show you a pic but,isn't much to see? Just a cylinder of O1 with a through hole in it.

Lube; having a machine shop.... we have quite an assortment of reaming and threading lubes. Have tried a few but.... none really work significantly better than Lee,LLA. AKA "mule snot" in cast bullet circles. The difference from those folks is,this isn't "so" much a lube for the bore,even though it has certain properties. It's more as a lube for the LG turning moment. And further details on the LLA,is that I pour this goo into empty Kiwi shoe polish tins,leaving them open to let the solvent/s burn off. The consistency,and appearance is exactly like the dang shoe polish.

Can't,and won't pretend to know exactly "why" it works so well. Honestly don't give a chit, it's that easy to do. It seems to uniform the noses like the old time construction,grading principle of,"cut 50,fill 50". It takes off the high spots,returning at least most of this into the low spots. The mule snot,filling in the spaces. Any excess lube isn't warranted and sorta makes a mess. This is why the LLA needs to be thought of more like a wax.

Any of you boys that have lathes,try making one. Reamers come in lots of shapes so won't bore you with listing them all and yes,I've even made some. I lapped some of the early ones but now prefer to leave the surface as it comes off the reamer,YMMV. Good luck with your shooting.