GrocMax,

I am familiar with that fan! Welcome to the club!

I felt obligated to quote the 'family' version.

GrocMax,

I am familiar with that fan! Welcome to the club!

Found an issue going from alpha/boilerplate/spaghettiwire so it can get changed easy to the finished product- lost current control, acted goofy.

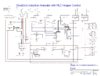

The RSP-750-48 PS manual wants you to reference (provide a 0v) the control voltage to pin 11 (gnd), this results in no workee correctly. With the 0v removed it works exactly as it should. So, control voltage to pin 5 and/or 7 only, no 0v ref on pin 10 or 11. I will change the diagram a few pages back and put a big note in. Sorta weird as I thought I had a solid 0v ref on pin 11, but I guess not. Now its back to absolute rock solid current control. Maybe this weekend I'll do a video and show control input voltage, what PS current and voltage that results in without a case, and with a case. Current stays where you set it, voltage varies.

Well doesn't look like I am allowed to edit the post a page back with the wiring diagrams, the 'bad' one has been deleted, here's the corrected one-

[/QUOTE]

[/QUOTE]Just a quick note- if the RSP-750-48 PS pulls down below about 5v it goes into fault and requires a on/off reset, so set current limit accordingly for each individual workpiece to operate above that. I would imagine the other models are very similar in protection schemes. Also the OPB716/718Z needs to be about 1/4"-3/8" from object, and a light colored tube (white or opaque white) works best, the dark grey PVC tube in my boilerplate tests isn't optimal by any means and isn't 100% reliable triggering, I think the background color it references is not right. The OPB100Z start switch with power resistors/config in drawing has been 100% reliable. Case feeding isn't a must by any means, more like a "because we can" feature.

Good to know on both points! I think I'll go with two of the OPB100Z's as I've tested it on a breadboard and it works well for input to my PLC with a 2.2k pull up resistor. I'll be resetting the timers with my PLC output rather than paralleling across the start/stop switches. In theory anyway lol!

Above there are comments about using 1000 uF capacitors.

Be very careful!!

If you put a capacitor accross relay contacts, you may be hastening the arcing problem. When the contacts are open, the capacitor will charge to the voltage across the contacts. When the contacts close, you are putting a dead short (the relay closed contacts) and a very large current will flow thru the contacts to dis-charge the capacitor!

Another pit fall is putting a large capacitor across your DC power supply. This supply probably has a current limit built in. If you put a big capacitor across this supply, say 1000 uF, when a fault occurs, the current will NOT be limited till the 1000 uF capacitor discharges! If your supply is limited at 20 Amps as an example and puts out 60 volts, if a fault occurs such as the oscillator not starting up correctly, a huge current spike may flow in one or both transistors instantly vaporizing them. A well designed power supply needs no capacitor on its output as the supply will have excellent regulation negating the need for external capacitors.

A properly selected relay is designed to switch a rated load current at its rated voltage. This current should be greater than the power supply current rating. Putting a capacitor across the relay contacts can exceed the rated current by an order of magnitude at least! As can placing a capacitor from either relay contact to ground!

Thanks for the warning, but now I still don't know what to do...

My power supply has no build in over protection or something since it's build

from 2 microwave transformers with rewound secondary's.

As protection I have a 15a fuse on the 120vac going into the transformers and a 20a fuse on the 40vdc after the bridge rectifier.

So I have the small diode (1n4007) wired in to protect the 12vdc coil side of relay and am now wondering if a

large diode for the 40vdc side would also work instead of the capacitor? (just like the low voltage relay side and trap door solenoid protection)

By the way, the 80a automotive relays did finally arrive today so I will give one of those a try once I have figured out what to do with wiring in a capacitor or not..

Hope you electronics experts can help.

In my response a few posts above, I wrote about the possibility of having a welded contact due to the discharge of the capacitor.

Anyway, from my experience, it is more important the gap in the contact rather than the capacitor.

The basic idea is to prevent the spark to keep on going when the relay goes to the N.O. position.

I am finally using a modified 40A relay, just by increasing the gap in the contacts. If you have a 80A relay, I asume that the gap problem is already solved from the factory.

I opened up the 80a and actually the gap was pretty much the same as the 40a one (about 1 millimeter)

So I bended over the NC contact and doubled the gap.

Did a quick test of the relay and the coil is still strong enough to close the circuit with the wider gap.

So I'll put it in and just skip the capacitor.

It isn't just the gap distance that determines voltage level the unit is capable of making/breaking for thousands of cycles reliably, its also very dependent on the contact material. Cheeseball junky no-name units will not use the more expensive or more appropriate material in the contacts.

WOW...... That is looking so nice !!. As bertn said the pump tank is the highest part of you cooling system, so all air should work it's way up and out. Is your radiator vertical ?

I did have a problem with air in the coolant lines on the first build (mod1) Because of space limitations I had it mounted sideways. Thought it would make no difference but I always had some air in the line. The newer unit (rev2) it was mounted vertical and have not seen an air bubble in that one since it self purged.

Gina

Thanks Kit-808...Good to know. I noticed I could get the air pockets to shift around a bit by tilting the case; guess I need to be more agressive and rotate it in all different orientations to get the air to the reservoir.to bleed the air you may need to rotate the case to move it, always have too with all my watercooled pc builds