You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What boring bar

- Thread starter Hal

- Start date

LVLAaron

Gold $$ Contributor

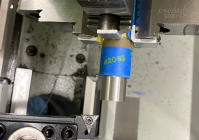

For a 223 chamber I use this tiny Accupro boring bar:

For all of the other "detail" work, crowns, larger chambers, bolt nose recesses, I love these tiny boring bars that take CCGT style polished inserts.

For all of the other "detail" work, crowns, larger chambers, bolt nose recesses, I love these tiny boring bars that take CCGT style polished inserts.

TS- C06K-SCLCR06 Solid carbide holder (Tungsten steel shock tool holder)CCMT0602 | eBay

Applicated inserts: CCMT0602 . wrench: T8.

www.ebay.com

BuffaloBill

Silver $$ Contributor

I bought one of these a couple months ago. I’ve only pre-bored one Creedmoor chamber with it but it cut nicely. What drew me to this one, other than the low cost, was the 3” length. To bore the 4-port brakes I needed a bit more reach.

Carbide boring bar | eBay

Find many great new & used options and get the best deals for Carbide boring bar at the best online prices at eBay! Free shipping for many products!

www.ebay.com

WSnyder

Silver $$ Contributor

Circle/Widia. I’ve been using these ever since Mike Bryant discovered them. For even smaller stuff like a PPC (or your 223) I use Micro 100 tooling.

www.travers.com

www.travers.com

MICRO 100 Solid Carbide Boring Tools

Use Micro 100 Solid Carbide Boring Bar to Make that Accurate Sized Hole. Ask any machinist and they will recommend you Micro 100's BB series for all your boring requirements. These bars are made up of solid carbide which is industrial-grade steel. Coating options are available which provides for...

Benchrest Central Forums

Benchrest Central Forum - The Absolute Source of Accuracy Components, Services, Accessories, and Information for the Precision Shooter

benchrest.com

Last edited:

gme

Site $$ Sponsor

I stumbled on to a Kennametal 3/16" carbide bar on e-bay,,,,,,, brand new, still in its original packaging. I think I paid $75 for it. It retails from MSC for over $400. Inserts are kinda' pricey, though

WSnyder

Silver $$ Contributor

Another old wives tale. There are plenty of modern carbide inserts and tooling with configurations that flat work on manual machines. Way too many of us have been doing it successfully for far too long now to keep this up. I have inserted tooling that'll take skim cuts in the tenths leaving beautiful finishes on my 13" Rockwell without high speeds or power.This is especially true on lathes that do not have enough speed/power to use carbide properly.

LVLAaron

Gold $$ Contributor

IMO you're better off using HSS rather than carbide to do chamber work. This is especially true on lathes that do not have enough speed/power to use carbide properly. This is rather complicated in regard to the rake angle, but carbide in general prefers fast speeds and more often than not you want to cut your chamber at slow speeds, so HSS is desirable for that. You could grind a tool bit blank to form a small boring bar, those work fine. You can also get HSS inserts from Arthur Warner as Bob Pastor has long recommended (Maker of Viper's Venum cutting oil). Not a bad option if you don't know how to grind a tool bit:

If you are asking about what boring bar to use, I have to guess you're not very competent with a lathe, so whatever you do, take your time and most of all be safe. In the case of chambering where you're basically sneaking up on your dimension from .001"-.003" at a pass, that is not enough for carbide to cut cleanly and carbide needs to turn fast in order to leave a clean finish. There are so many factors involved here I just can't over emphasize to be safe no matter what you do.

That's why I mentioned using "GT" style polished inserts. They are sharp as a cats claw and provide a beautiful finish. They cut easier than HSS.

I use the Micro 100 boring bars and this:

The little solid carbide ones snap very easily, light cuts and I don't even think about using them on interrupted cuts.

The little solid carbide ones snap very easily, light cuts and I don't even think about using them on interrupted cuts.

Dusty Stevens

Shiner

I use carbide exclusively and have for 20+ yrs as has pretty much every successful gunsmith has. Kennametal, iscar, pretty much all the toolmakers have inserts made for our type work

HS tools are OK, as long as you slow down to what they can handle. When I first started machining, in 1974, that's what we had, HS tooling. If you had a tool bit that had brazed carbide you really had something!! Inserts hadn't been thought of , yet...... HS runs at 100SFM (round number there), none of this 450SFM+ we run now with good carbide inserts. And, as mentioned above, there's an insert made for any imaginable material you can cut. Tool making from a HS blank is just for us "old men".

Believe it or not, there was machining before carbide inserts. We cut all kinds of steels with HS , because that's what we had. You had to actually know something about tool geometry, it wasn't as simple as removing a worn insert and putting a new edge to the work. Tough to cut alloys have been around for a long time.I work with 4140 quite a lot at work. We use Kennametal tools with carbide inserts.

Even, or because of, the feeds & speeds we use, we go through a fair number of inserts. Even with coolant.

Not sure how HSS would hold up against it.

Last edited:

spitfire_er

Silver $$ Contributor

I use small solid carbide boring bars similar to shown above. You are usually only taking a few light cuts with them for this purpose.

AckleymanII

Gold $$ Contributor

I have been using the Widea/Circle C, 3/16 & 1/4" solid carbide boring bars, 6" with FCBI and CCBI inserts for a long time.

Use high quality inserts, they are worth it in the long run.

Use high quality inserts, they are worth it in the long run.

Similar threads

- Replies

- 5

- Views

- 1,384

- Replies

- 7

- Views

- 1,335

- Replies

- 24

- Views

- 4,166

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.