So I started playing around with the FL die last night. Long(er) story short, I have to size the neck and deprime with my neck sizer die then bump the rest of the brass with the FL die. If I bump with the FL die and dont do anything else the FL die wont fully size the neck. After a couple of screwed up cases I finally figured out what was going on and then cleaned the gun a little to make sure I wasnt screwing up the measurements, but now I have an OAL of 2.780" with 40gr of 4350 and no funny chambering issues. I'm not confident it will shoot better but atleast I learned something in the process. I will actually be doing "Long range load development at 100 yards" at some point so I'm sorry if it seems I have hijacked the thread. Thanks for everything everyone.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Long range load development at 100 yards.

- Thread starter Erik Cortina

- Start date

Erik what is your experience with how much temp variance the load can handle when working with your method? Say if I worked load up in 85F temp and got it tuned. Now it is starting to be in the low 60s. How much impact will this have?

Also once you find your charge and do seating depth test, should you go back and verify if the load window is still the same? I figure seating affects pressure and might change the node +/- a few tenths of a grain. Curious what you have seen

Thanks

Also once you find your charge and do seating depth test, should you go back and verify if the load window is still the same? I figure seating affects pressure and might change the node +/- a few tenths of a grain. Curious what you have seen

Thanks

Erik Cortina

Team Lapua Brux Borden Captain

savageshooter86 said:Erik what is your experience with how much temp variance the load can handle when working with your method? Say if I worked load up in 85F temp and got it tuned. Now it is starting to be in the low 60s. How much impact will this have?

Also once you find your charge and do seating depth test, should you go back and verify if the load window is still the same? I figure seating affects pressure and might change the node +/- a few tenths of a grain. Curious what you have seen

Thanks

It depends on the powder used. If powder is fairly insensitive you'll be fine.

Another trick is that if you know your accuracy window is from 50.0 gr - 50.6 gr, I load 50.3 most of the time, but if I know my load was worked up in 80° weather and I'm going to shoot in 60° weather, I will load 50.5 gr. to make sure I'm in the window.

Seating depth does not affect pressure that much.

Thanks Erik. I'm using Varget so I should be good

I switched to 87gr Vmax's with 4064. I loaded and tested this method and it showed a TON of improvement. The gun held yesterday in 1" groups with 3 holes out of 5 touching. I didn't take pics of the targets but I'm definetly on the right track. The wind was blowing so hard I couldn't fully trust the data but I will test again. Next time I'll get pics. Thank you for this thread and all the help.

Hi Erik,

I have been enjoying your thread with all the great advice! Can you please review and answer a few questions about my load?

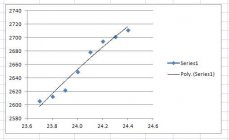

OCW done at 100 yards with 223 handloads. Gas gun with 20 inch Lothar Walther barrel 1-8 twist with Wylde chamber, 77 grain Nosler CC, TAC powder, Lapua case, Wolf SRM primer, and bullets seated to mag length (1.886†OTB). Charges tested were between 23.7 to 24.4 grains. Atmospheric conditions 45 °F, 42.5 % humidity, baro at 29.5 inHg, and calm. Rounds were shot round Robin style after 3 foulers. MV measured with a Ohler Model 35 with 4’ rail.

I used only use 0.1 grain increments increase in powder charge looking for a node at the higher charge range for shooting at 600 yards. My charges according to Ramshot were all over max for 223 Rem for a 77 grain SMK (23.4 grain 2750 fps) although not for the same bullet at 5.56 NATO pressure (24.8 grain 2,902 fps). No significant pressure signs except for slightly flat primers at two highest charges.

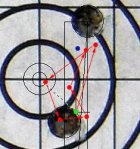

I have used OnTarget software to calculate the center for each group and their location is show in the graphic overlay on part of the target for the lowest 23.7 grain charge (with green dot). The red arrows show the direction of movement for the group center of each higher charge except for the last charge which is colored blue (too close for an arrow). MV increased in an S-shape curve slightly flattening out at the last 3 higher charges. For the 3 shot groups ES/SDEV was best at 24.0 and 24.3 grain.

My question is it appears that this combo seem to have a pretty narrow node – I am guessing between 23.9 to 24.2 grains? Have you seen this before and will this be a problem? If I go for 24.0 grain to do seating depth adjustment to get the accurate results would I get in trouble when atmospheric temperature goes up from today’s 45 degree to 90 degree? Or should I go to the low end of the node i.e. 23.9 grain so that I have more room at the higher temperature?

I have been enjoying your thread with all the great advice! Can you please review and answer a few questions about my load?

OCW done at 100 yards with 223 handloads. Gas gun with 20 inch Lothar Walther barrel 1-8 twist with Wylde chamber, 77 grain Nosler CC, TAC powder, Lapua case, Wolf SRM primer, and bullets seated to mag length (1.886†OTB). Charges tested were between 23.7 to 24.4 grains. Atmospheric conditions 45 °F, 42.5 % humidity, baro at 29.5 inHg, and calm. Rounds were shot round Robin style after 3 foulers. MV measured with a Ohler Model 35 with 4’ rail.

I used only use 0.1 grain increments increase in powder charge looking for a node at the higher charge range for shooting at 600 yards. My charges according to Ramshot were all over max for 223 Rem for a 77 grain SMK (23.4 grain 2750 fps) although not for the same bullet at 5.56 NATO pressure (24.8 grain 2,902 fps). No significant pressure signs except for slightly flat primers at two highest charges.

I have used OnTarget software to calculate the center for each group and their location is show in the graphic overlay on part of the target for the lowest 23.7 grain charge (with green dot). The red arrows show the direction of movement for the group center of each higher charge except for the last charge which is colored blue (too close for an arrow). MV increased in an S-shape curve slightly flattening out at the last 3 higher charges. For the 3 shot groups ES/SDEV was best at 24.0 and 24.3 grain.

My question is it appears that this combo seem to have a pretty narrow node – I am guessing between 23.9 to 24.2 grains? Have you seen this before and will this be a problem? If I go for 24.0 grain to do seating depth adjustment to get the accurate results would I get in trouble when atmospheric temperature goes up from today’s 45 degree to 90 degree? Or should I go to the low end of the node i.e. 23.9 grain so that I have more room at the higher temperature?

Attachments

Erik Cortina

Team Lapua Brux Borden Captain

24.0 is what I would fine tune. However, the results are not very promising and might need to change powders or primers if 24.0 doesn't hold. Your ES #'s are huge!

Another seating depth test at 100. 284 Winchester, tula primers, 55.3 of H4831SC. Tested from 2.522(my zero reference point) out to 30 thousandths jump. Light breeze from L-R, and temps were 65-68.

What depth should I run with based on the results ?

Thanks.

What depth should I run with based on the results ?

Thanks.

Attachments

Erik Cortina

Team Lapua Brux Borden Captain

Lawrence97, -.015 and .018" both look good. Load -0.16" and it will give you room for error on both sides. Good luck.

Erik Cortina

Team Lapua Brux Borden Captain

Thanks RyanS.

Raythemanroe

Bullet Whisperer

.013 is what I like, I like to shoot for the middle.

Erik Cortina

Team Lapua Brux Borden Captain

raythemanroe said:.013 is what I like, I like to shoot for the middle.

Why would you pick .013"? .012" does not look good.

-.015" and -.018" and -.021" are the best groups.

Seating question....I loaded seven 3-round groups using different seating depths all at the same powder charge. I did the powder charge tests seated .010" off the lands at an OAL of 2.710". The rifle is showing major improvement but this will be the first time I have done seating tests. I made the longest ones .005" off the lands seated at an OAL of 2.715" and shortened them in .003" incriments: 2.715", 2.712" and so on....the closest ones I made were .005" off the lands because I'm affraid to get any closer since according the Hornady RLM V9 I am allrerady over max charge. I believe max is 37.1 and the most accurate shot I could get without signs of pressure was 38gr. Should I be starting closeer to the lands or run what I got and see what happens? Standard 243 with 87gr Vmax's-38gr of 4064 Fed 210 primers

Erik Cortina

Team Lapua Brux Borden Captain

Run what you have and see how it shoots.

johnnyi

Gold $$ Contributor

And after burning through lots of components chasing loads between 168 AMAX and 175 SMK. Both showed good results at 100 and thought I tracked down the ideal load. As I proceeded to 200 where the groups fell apart with the 175 SMK. 168 AMAX produced what I would expect as you proceed out to longer yardages. Not so happy with the results I opted to switch to Bergers and give those a whirl... I finally tracked down some 185 Bergers. Berger testing ran into hunting season where the local range became, well, lets just say BUSY. So I opted to just do my testing at 200 yard line. I never found any confirmed information how to proceed with a new load development. Start with powder or start with seating depth? So I took a guess and found a speed that I thought could carry me all the way out to 1000, if all looked good... I opted for the beginning charge of 41.5 Grains of Varget, loaded into Lapua brass, BR2 Primers, and the 185 Bergers. I felt like the estimated speeds I found for a 24" barrel would give me about 2500-2525 fps. So I went with that. I found the info about testing for VLD bullets to start with .010 into the lands, then -.040, -.080 and I opted to forgo any deeper as the bullet to me seemed shoved too far below the shoulder. So I stopped at the .080 jump. Rifle is a KMW 700 action with Kreiger 1:11 24" barrel.

Here is the seating Depth target. (ignore the SMK groupings that are in the middle and the top left) I started bottom row with +.010 into the lands. off lands -.040 (target was looking good so I wanted to be sure it repeated) then -.082. bottom row far right I tested the .040 again. I felt like the .040 jump was a decent place to work around to see if I could tweak around that area to see what happens. Top row #2 from left -.042

Am I going in the right direction?

Next trip I decided to go with the .040 jump and go to powder starting at 41.5 no signs of any pressure issues so I stepped up .2 grains per grouping. shooting again left to right, however this time starting top row. Again all at 200 to try to bypass the crowd at 100.

Here is rifle. Showing with Mark4 Leupold. Scope had been removed so I have been doing all my testing with a different scope. Bushnell 4200

6-24 Mildot scope.

Here is the seating Depth target. (ignore the SMK groupings that are in the middle and the top left) I started bottom row with +.010 into the lands. off lands -.040 (target was looking good so I wanted to be sure it repeated) then -.082. bottom row far right I tested the .040 again. I felt like the .040 jump was a decent place to work around to see if I could tweak around that area to see what happens. Top row #2 from left -.042

Am I going in the right direction?

Next trip I decided to go with the .040 jump and go to powder starting at 41.5 no signs of any pressure issues so I stepped up .2 grains per grouping. shooting again left to right, however this time starting top row. Again all at 200 to try to bypass the crowd at 100.

Here is rifle. Showing with Mark4 Leupold. Scope had been removed so I have been doing all my testing with a different scope. Bushnell 4200

6-24 Mildot scope.

Erik Cortina

Team Lapua Brux Borden Captain

Johnnyi, your seating depth movements are too coarse, you are shooting in the dark trying to find the correct seating depth. Move only in .003" increments and you'll see groups get smaller and them bigger. Good luck.

johnnyi

Gold $$ Contributor

Thanks Erik

I did the VLD tuning method to get me rolling.

http://bulletin.accurateshooter.com/2009/03/berger-tips-for-loading-vld-bullets/

Seemed like .040 jump was the best range to shoot in. I did a little testing around that seating range to see how the results looked. I got a little anxious after all the tuning on the SMK and AMAX. So I moved to test powder charges. After looking at how far down the seating is on my bergers, seems like I really have the bullet seated deep... Base of the bullet is well below the shoulder. My barrel seems to have a shallow chamber. Base of my the case to the ogive touching the lands is 2.222. I will circle back and do some more seating depth testing.

Where would you suggest to start the seating depth testing and reducing .003 per group?

I did the VLD tuning method to get me rolling.

http://bulletin.accurateshooter.com/2009/03/berger-tips-for-loading-vld-bullets/

Seemed like .040 jump was the best range to shoot in. I did a little testing around that seating range to see how the results looked. I got a little anxious after all the tuning on the SMK and AMAX. So I moved to test powder charges. After looking at how far down the seating is on my bergers, seems like I really have the bullet seated deep... Base of the bullet is well below the shoulder. My barrel seems to have a shallow chamber. Base of my the case to the ogive touching the lands is 2.222. I will circle back and do some more seating depth testing.

Where would you suggest to start the seating depth testing and reducing .003 per group?

Similar threads

- Replies

- 61

- Views

- 14,838

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.