urbanrifleman

Site $$ Sponsor

No way to know, on a prefit, unless you have the action in hand at some point.

Yes. Or a barrel.

No way to know, on a prefit, unless you have the action in hand at some point.

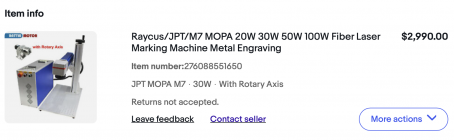

ebay laser arrived today. Ordered November 5th and arrived December 1st - 27 days. Found some settings that worked on stainless and after adjusting focal length, I tried it out on a stub. Laser seems okay. I will say that the lead screw assembly is VERY cheaply made. It might be fine as long as treated very carefully. The bottom table is light metal and the threads are rough everywhere. It is stable. Did not come with glasses, Need to figure which to purchase. I didn't realize that EzCAD Lite doesn't run on a MAC. I had to dig out an old PC laptop and had some issues with a driver and with the stability of the program. Probably the laptop. The engraver comes with no instruction at all--none. EzCad seems to be set up on the USB but I am a little confused about the selection of laser. I set it to JPT but the original parameters had it set to something different-maybe IPG-YLP.

Knowing that we all like quality equipment this marker is very marginal. Here is a first cut at marking a barrel. All characters are just random.

View attachment 1498478

That deer pictures is incredible!! Well done.A couple of recent jobs..the photos are getting popular. They're on coated aluminum. View attachment 1499084View attachment 1499089

Good to know. I originally ordered the 110x110 but my system came with a 150x150. Sounds like that is just about right.

I played around with hatching patterns for text and it is crazy how much time you can save or create by changing some of those settings.

Did you use the default 100mm mirror distance in LightBurn for the curved surface or did you actually measure?

Hank