GREATING James,So far testing the annealer has worked out great just working through one issue that i am not sure on and maybe someone can provide any insite. No matter where in the coil I put the case with tempilaq 750 the same results happen just times are either longer or slower. So when i start the heating cycle and you can see the tempilaq disappearing from the top of the case mouth downward to the shoulder which i believe is normal. My concern is that if i run it so that you see annealing marks maybe 1/4" below the shoulder (most pics i see on the net) the case mouth heats up and glows red which i believe is over the 750 degrees and maybe over annealing it. what i have done to not heat up the case is if i turn off the lights and run the cycle till it just barely turns red then reduce the time by 1/2-1 sec the annealing seems to only reach the shoulder or 1/16-1/8" below the shoulder. Is this ok or something else i should be looking at? i have tried this mainly on Military LC, Herters and Prvi brass.

also here is my Arduino code as well as the Nextion LCD firmware/Design file.

thanks

James

Thank you for posting your code and sharing your build.

I had all my programming flow charts on how I would do it, and it is the same vision from yours... So, you have saved me a tons of time!! thank you!!

May I ask how did you overcome the SoftwareSerial.h ? since the Due seems not "supporting " it.

I've added all the extra libraries noted from your Readme.txt, but all compilation fails at the same point; from the Nextionupload.cpp that is looking for the SoftwareSerial.h

I'm working on the different version of the Arduino IDE from 1.8.5 to .13 and none of them works.

The Nexion editor is V0.53, that I had it from couple years ago. so all good from there.

Hoping to hear back form you or anyone that may have the solution or a pointer to the right direction, all are welcome!!!

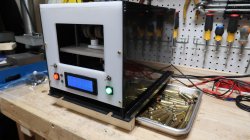

only missing the Main Power supply, the 100A SSR and the SD card reader extension.