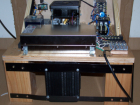

My first annealer was built with the help of hollywood. He worked long and hard on finding the right coil size. He also came up with the water cooled coil and the radiator/pump system for it.

I added the timer system, trap door, and voltage/current monitor meter. Together we came up with what I think is a really great annealer. Since Mod1 (the first one) I've added a few improvements, this is Rev2.

If you were thinking of building one, I hope this helps.

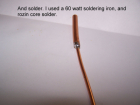

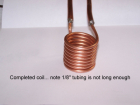

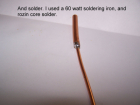

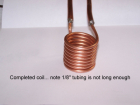

Making the coil.... See photos. Note... Inside diameter of the coil is about 1 1/8 inches. BTW PVC pipe is schedule 40 3/4" pipe.

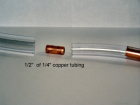

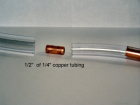

Since the power connections from the annealer board to the coil are set up for ¼ “ tubing, we must transition from 1/4” copper tubing to the coil's 1/8 size.

See the 4 pictures on this. Remember to leave enough of the 1/8 tubing to reach the trap door location from the inductor PCB from the 1/4” tubing. Easier to move the 1/8 tubing than the 1/4” tubing

After your coil is complete, slightly separate the coils so they do not touch and dunk in shellac or varnish to insulate them.

One of the things I've run into with the latest build was that the radiator and the coolant pump both had 3/8” inch fittings, but I had 1/4” tubing coming from and going to the inductor PCB.

See the 3 pictures on how to deal with this.

Hint..... After cutting the copper tubing, (using a pipe cutter) ether the 1/8” or 1/4”, ream out the opening, as the cutting process tends to partly close the opening.

Parts list

Items that were bought through Amazon

(1) SainSmart1000W ZVS low voltage induction heating board. $36.99

(2) Yosoo SC-300TDC12V water cooling pump tank $22.04

(3) Thermaltake 1000cc Liquid coolant $15.99

(4) Refigeration Copper Tubing 1/8” x 50' $30.88

(5) AGPtek 12 Pipe Aluminum Heat Exchanger Radiator $16.99

(6) Packard C230 2 Pole 30 Amp Contactor, 120 Volt Coil $ 9.00

(7) DROK Digital V/C measurement DC 0-100V/50Amp meter $16.42

(8) uxcell 5 Pcs, 6 Position screw terminal strip. $ 5.89

(9) Sestos Digital Quartic Timer Relay Switch 100-240V B3S $29.96

Items bought through Jameco www.jameco.com

(1) 2125931 Fan, 120VAC 2 each @ $13.95 $27.90

(2) 196817 Fan Guard & filter 2 each @ $2.19 $ 4.38

(3) 323337 12V@3A power supply $12.95

(4) 295929 48V12.5A 600 Watt Power Supply $76.95

(5) 34462 Varistor 130VAC $ .39

(6) 69439 Fuse, Fast Acting 3A .25”x1.25” (3) $ 1.05

(7) 69570 Fuse Slo Blow 10A .25”x1.25" (1) $ .59

(8) 317825 Switch, Toggle on/off $ 2.55

(9) 1711947 Fuse Holder .25” 1.25” (4) $ 3.96

(10) 2202335 Solenoid Tubular-pull 12VDC $ 7.95

(11) 2153705 Wire, hook up kit $16.95

(12) 36011 1N4007 Diode (min order 10 @ 5 cents) $00.50

(13) 315432 SPST Momentary contact switch 2 @ $1.09 $ 2.18

Note... not all parts were ordered from on-line. Numerous items were purchased from my local hardware store ie vinyl tubing, 1/4” copper tubing, tube clamps, etc.

I added the timer system, trap door, and voltage/current monitor meter. Together we came up with what I think is a really great annealer. Since Mod1 (the first one) I've added a few improvements, this is Rev2.

If you were thinking of building one, I hope this helps.

Making the coil.... See photos. Note... Inside diameter of the coil is about 1 1/8 inches. BTW PVC pipe is schedule 40 3/4" pipe.

Since the power connections from the annealer board to the coil are set up for ¼ “ tubing, we must transition from 1/4” copper tubing to the coil's 1/8 size.

See the 4 pictures on this. Remember to leave enough of the 1/8 tubing to reach the trap door location from the inductor PCB from the 1/4” tubing. Easier to move the 1/8 tubing than the 1/4” tubing

After your coil is complete, slightly separate the coils so they do not touch and dunk in shellac or varnish to insulate them.

One of the things I've run into with the latest build was that the radiator and the coolant pump both had 3/8” inch fittings, but I had 1/4” tubing coming from and going to the inductor PCB.

See the 3 pictures on how to deal with this.

Hint..... After cutting the copper tubing, (using a pipe cutter) ether the 1/8” or 1/4”, ream out the opening, as the cutting process tends to partly close the opening.

Parts list

Items that were bought through Amazon

(1) SainSmart1000W ZVS low voltage induction heating board. $36.99

(2) Yosoo SC-300TDC12V water cooling pump tank $22.04

(3) Thermaltake 1000cc Liquid coolant $15.99

(4) Refigeration Copper Tubing 1/8” x 50' $30.88

(5) AGPtek 12 Pipe Aluminum Heat Exchanger Radiator $16.99

(6) Packard C230 2 Pole 30 Amp Contactor, 120 Volt Coil $ 9.00

(7) DROK Digital V/C measurement DC 0-100V/50Amp meter $16.42

(8) uxcell 5 Pcs, 6 Position screw terminal strip. $ 5.89

(9) Sestos Digital Quartic Timer Relay Switch 100-240V B3S $29.96

Items bought through Jameco www.jameco.com

(1) 2125931 Fan, 120VAC 2 each @ $13.95 $27.90

(2) 196817 Fan Guard & filter 2 each @ $2.19 $ 4.38

(3) 323337 12V@3A power supply $12.95

(4) 295929 48V12.5A 600 Watt Power Supply $76.95

(5) 34462 Varistor 130VAC $ .39

(6) 69439 Fuse, Fast Acting 3A .25”x1.25” (3) $ 1.05

(7) 69570 Fuse Slo Blow 10A .25”x1.25" (1) $ .59

(8) 317825 Switch, Toggle on/off $ 2.55

(9) 1711947 Fuse Holder .25” 1.25” (4) $ 3.96

(10) 2202335 Solenoid Tubular-pull 12VDC $ 7.95

(11) 2153705 Wire, hook up kit $16.95

(12) 36011 1N4007 Diode (min order 10 @ 5 cents) $00.50

(13) 315432 SPST Momentary contact switch 2 @ $1.09 $ 2.18

Note... not all parts were ordered from on-line. Numerous items were purchased from my local hardware store ie vinyl tubing, 1/4” copper tubing, tube clamps, etc.

Attachments

Last edited: