You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I have Recently Learned About Chambering

- Thread starter INTJ

- Start date

A simple method I use for timing fluted barrels is,unscrew current barrel.clean threads,shoulder,action face etc.retighten with torque wrench.i use 70ftlbs.scribe inline witness marks on barrel and action.slacken action then screw back up to shoulder by hand measure the gap in between witnesses marks and record dimension.lightly mark straight lines down centre of flutes onto barrel tennon.thread tennon and machine barrel shoulder until one obtains pre recorded dimension inbetween witness mark's.when chambering,headspace is done and final fit is ready torque to 70ftlbs and your on the money.ive found it work's well.just another way to skin the cat.

xr650rRider

Silver $$ Contributor

How long is that barrel you have in there? Just wondering how short you can go with that lathe

That barrel was 26". Can do around 19" thru headstock. Any shorter, I've got extensions to either screw onto tenon or screw onto muzzle thread. Unless it's an Thompson Encore or Contender needing threaded muzzle, then anything under about 22" has to be done between centers, then steady rest.

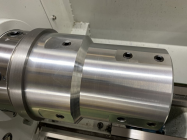

I use a similar jig for short stuff. Ruger mark 2 barrel in that pic. Got a some kind of micron filter too.Not possible on a manual lathe. I don't know what additional capabilities a CNC lathe might have- but unless there's some mechanism whereby the contact of the insert to the tenon is precisely timed to the spindle rotation it can't happen there either.

This is above my pay grade, but far as I know the only way to time threads as used in shouldered prefits (or the "clocking the muzzle" application to which you're referring) is by thread milling.

Simple double-spider rig in a 4-jaw is what I use for shorties.

Only thing I can add to the flush system topic is type of filter I use, haven't seen it mentioned before.

AO Smith water filtration setup, with 20 micron filter.

Magnets, of course- but they don't do a thing for stainless chips. Layer of the "universal" type plastic air filter stuff cut to fit in the drain pan

Attachments

Understood, thanks.Even with cnc you cant get the timing perfect. Pitch diameter will change timing. Actions do have variation in the thread pd. Even if you start the thread in the same place timing will vary because the pd will vary with tool changes.

This further boggles my mind with shouldered prefits.

Assuming the receiver mfg holds tolerances to +/- .001 (I believe I read that from Defiance- correct me if I'm wrong) for rear face of lug to boltface, and also for receiver ring face to lug abutments; and then the barrel machinist has to hold similar tolerances for shoulder to breech, and chamber depth/shoulder to face of go gage- I don't understand how tolerance stacking given all these ops works out.

Or, maybe it doesn't, all the time...

Dusty Stevens

Shiner

Well if you have a bolt end gap of .007 or .009 does it really matter?Understood, thanks.

This further boggles my mind with shouldered prefits.

Assuming the receiver mfg holds tolerances to +/- .001 (I believe I read that from Defiance- correct me if I'm wrong) for rear face of lug to boltface, and also for receiver ring face to lug abutments; and then the barrel machinist has to hold similar tolerances for shoulder to breech, and chamber depth/shoulder to face of go gage- I don't understand how tolerance stacking given all these ops works out.

Or, maybe it doesn't, all the time...

Judd

Gold $$ Contributor

I know this is somewhat of a taboo topic here but curiosity also killed the cat so here goes…safe to assume all pre-fits are indicated on both ends rather than back of the chamber and throat? I assume thi s because there isn’t action timing with that method.

At this point, I have used a Viper fixture and I’ve also made 8” barrel extensions that thread onto the chamber end. I bought a bunch of 1.25” bar stock when I first got my lathe to “practice” on…the extra made perfect extensions.

At this point, I have used a Viper fixture and I’ve also made 8” barrel extensions that thread onto the chamber end. I bought a bunch of 1.25” bar stock when I first got my lathe to “practice” on…the extra made perfect extensions.

Alex Wheeler

Site $$ Sponsor

If you dont time barrels it wont matter. If you do it will. Most actions do pretty well with headspace. Pitch diameter not so much.Understood, thanks.

This further boggles my mind with shouldered prefits.

Assuming the receiver mfg holds tolerances to +/- .001 (I believe I read that from Defiance- correct me if I'm wrong) for rear face of lug to boltface, and also for receiver ring face to lug abutments; and then the barrel machinist has to hold similar tolerances for shoulder to breech, and chamber depth/shoulder to face of go gage- I don't understand how tolerance stacking given all these ops works out.

Or, maybe it doesn't, all the time...

LVLAaron

Gold $$ Contributor

Understood, thanks.

This further boggles my mind with shouldered prefits.

Assuming the receiver mfg holds tolerances to +/- .001 (I believe I read that from Defiance- correct me if I'm wrong) for rear face of lug to boltface, and also for receiver ring face to lug abutments; and then the barrel machinist has to hold similar tolerances for shoulder to breech, and chamber depth/shoulder to face of go gage- I don't understand how tolerance stacking given all these ops works out.

Or, maybe it doesn't, all the time...

Prefits are easy.. but timing the barrel isn't possible if you don't have the action in hand.

LVLAaron

Gold $$ Contributor

All this talk has me wanting to start a project.

What are the major components needed? I found the pump and motor on amazon...

Tank > pump pre-filter > pump > valve > micron filter > barrel attachment

I assume a pressure gauge would be desired... after the valve?

What are the major components needed? I found the pump and motor on amazon...

Tank > pump pre-filter > pump > valve > micron filter > barrel attachment

I assume a pressure gauge would be desired... after the valve?

Procon 102A140F11PA Brass Rotary Vane Pump, 3/8" NPTF, 154 GPH: Industrial Rotary Vane Pumps: Amazon.com: Industrial & Scientific

Procon 102A140F11PA Brass Rotary Vane Pump, 3/8" NPTF, 154 GPH: Industrial Rotary Vane Pumps: Amazon.com: Industrial & Scientific

smile.amazon.com

Marathon H684 48Y Frame Open Drip Proof 5KH36MNA445X Carbonator Pump Motor, 1/2 hp, 1800/1500 RPM, 100-120/200-240 VAC, 1 Split Phase, 2 Speeds, Ball Bearing, Rigid Base: Industrial Products: Amazon.com: Tools & Home Improvement

Marathon H684 48Y Frame Open Drip Proof 5KH36MNA445X Carbonator Pump Motor, 1/2 hp, 1800/1500 RPM, 100-120/200-240 VAC, 1 Split Phase, 2 Speeds, Ball Bearing, Rigid Base: Industrial Products: Amazon.com: Tools & Home Improvement

smile.amazon.com

Dusty Stevens

Shiner

Id use a back pressure regulator on a return to the tank. Think fuel injection systemsAll this talk has me wanting to start a project.

What are the major components needed? I found the pump and motor on amazon...

Tank > pump pre-filter > pump > valve > micron filter > barrel attachment

I assume a pressure gauge would be desired... after the valve?

Procon 102A140F11PA Brass Rotary Vane Pump, 3/8" NPTF, 154 GPH: Industrial Rotary Vane Pumps: Amazon.com: Industrial & Scientific

Procon 102A140F11PA Brass Rotary Vane Pump, 3/8" NPTF, 154 GPH: Industrial Rotary Vane Pumps: Amazon.com: Industrial & Scientificsmile.amazon.com

Marathon H684 48Y Frame Open Drip Proof 5KH36MNA445X Carbonator Pump Motor, 1/2 hp, 1800/1500 RPM, 100-120/200-240 VAC, 1 Split Phase, 2 Speeds, Ball Bearing, Rigid Base: Industrial Products: Amazon.com: Tools & Home Improvement

Marathon H684 48Y Frame Open Drip Proof 5KH36MNA445X Carbonator Pump Motor, 1/2 hp, 1800/1500 RPM, 100-120/200-240 VAC, 1 Split Phase, 2 Speeds, Ball Bearing, Rigid Base: Industrial Products: Amazon.com: Tools & Home Improvementsmile.amazon.com

WSnyder

Silver $$ Contributor

Add a pressure relief/bypass valve to adjust final pressure. Install it before the shutoff/ball valve (pump side). It will also bypass back to the tank when you shut the valve.All this talk has me wanting to start a project.

What are the major components needed? I found the pump and motor on amazon...

Tank > pump pre-filter > pump > valve > micron filter > barrel attachment

I assume a pressure gauge would be desired... after the valve?

Procon 102A140F11PA Brass Rotary Vane Pump, 3/8" NPTF, 154 GPH: Industrial Rotary Vane Pumps: Amazon.com: Industrial & Scientific

Procon 102A140F11PA Brass Rotary Vane Pump, 3/8" NPTF, 154 GPH: Industrial Rotary Vane Pumps: Amazon.com: Industrial & Scientificsmile.amazon.com

Marathon H684 48Y Frame Open Drip Proof 5KH36MNA445X Carbonator Pump Motor, 1/2 hp, 1800/1500 RPM, 100-120/200-240 VAC, 1 Split Phase, 2 Speeds, Ball Bearing, Rigid Base: Industrial Products: Amazon.com: Tools & Home Improvement

Marathon H684 48Y Frame Open Drip Proof 5KH36MNA445X Carbonator Pump Motor, 1/2 hp, 1800/1500 RPM, 100-120/200-240 VAC, 1 Split Phase, 2 Speeds, Ball Bearing, Rigid Base: Industrial Products: Amazon.com: Tools & Home Improvementsmile.amazon.com

I recommend one of these:

www.gretanrifles.com

www.gretanrifles.com

I'll take a pic of my valve body and post tomorrow.

Model BTS | gretanrifles

"BARREL THROUGH SPINDLE"This barrel adapter was designed for the gunsmith with smaller lathes in mind. If your chambering method is to mount the barrel through the spindle bore, and indicate the chamber end at the chuck, and the muzzle out the rear of the spindle with a spider.THIS is just what...

I'll take a pic of my valve body and post tomorrow.

BuffaloBill

Silver $$ Contributor

I started with a reservoir from Northern Tool, then welded up a frame to hold the pump, filter, valving, and regulator, trying to keep it all compact and mobile. My catch pan drain hose is marginally big enough. Using Ridgid extreme oil I have to pause a few mins to let it catch up sometimes. Not really a problem as I’m in no hurry.

Only guessing but I'd say the in / out may be the other way around so pressure will relieve if the filter is blocked and you use the gauge to check how blocked the filter is.

The secondary relief valve on the back of the splash back would be doing the barrel side relief.

I have mine mounted on the splash back the same and find it really handy to be able to watch gauges and adjust pressures on the fly. Air flush is also helpful but just be prepared for $#!+ to be going everywhere if you don't have the end covered in some way!!

I started with a reservoir from Northern Tool, then welded up a frame to hold the pump, filter, valving, and regulator, trying to keep it all compact and mobile. My catch pan drain hose is marginally big enough. Using Ridgid extreme oil I have to pause a few mins to let it catch up sometimes. Not really a problem as I’m in no hurry.View attachment 1358662

Which pump and motor did you use?

Shop around a bit. I got mine from eBay for about $75. That was the pump, motor, base and a surge tank (which I didn't have a use for, but sold to a welder friend as part of a TIG cooler project he was doing for $25)All this talk has me wanting to start a project.

What are the major components needed? I found the pump and motor on amazon...

Tank > pump pre-filter > pump > valve > micron filter > barrel attachment

I assume a pressure gauge would be desired... after the valve?

Procon 102A140F11PA Brass Rotary Vane Pump, 3/8" NPTF, 154 GPH: Industrial Rotary Vane Pumps: Amazon.com: Industrial & Scientific

Procon 102A140F11PA Brass Rotary Vane Pump, 3/8" NPTF, 154 GPH: Industrial Rotary Vane Pumps: Amazon.com: Industrial & Scientificsmile.amazon.com

Marathon H684 48Y Frame Open Drip Proof 5KH36MNA445X Carbonator Pump Motor, 1/2 hp, 1800/1500 RPM, 100-120/200-240 VAC, 1 Split Phase, 2 Speeds, Ball Bearing, Rigid Base: Industrial Products: Amazon.com: Tools & Home Improvement

Marathon H684 48Y Frame Open Drip Proof 5KH36MNA445X Carbonator Pump Motor, 1/2 hp, 1800/1500 RPM, 100-120/200-240 VAC, 1 Split Phase, 2 Speeds, Ball Bearing, Rigid Base: Industrial Products: Amazon.com: Tools & Home Improvementsmile.amazon.com

This is essentially what I bought but for less:

" McCann's " MAC200092 COMMERCIAL CARBONATOR PUMP WITH TANK FOR SODA BEER SYSTEM | eBay

MODEL: MAC200092. Why buy new?. Then, we will re-list the item. We will give you any information you need, and assist you all that we can in expediting your claim. If you do not have one, we can refer you to one.

www.ebay.com

I bought a filter from McMaster Carr for another $35 and tubing/fittings from Lowes.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Similar threads

- Replies

- 119

- Views

- 12,114

- Replies

- 33

- Views

- 2,777

- Replies

- 7

- Views

- 2,252

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.