You probably need a VLD stem, current stem may be bottoming out on meplat giving you inconsistent measurements.

You can drill and lap your current stem and or bed it with JBweld and a projectile.

Try sorting by overall length, this will help with variations from ogive to meplat.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OGIVE Distance

- Thread starter Rick Ratzlaff

- Start date

-

- Tags

- ogive

Thanks LH, I hear that. I will never again get a mixed bag of brass. It is a hunting rifle and if I could get consistent 3/4" MOA, I'd sell it.

Rank Amateur

Gold $$ Contributor

Sleeve in seating die is intended to align components. Sleeve is not the part that pushes bullet down to seat it in the case. Ogive is the entire bullet surface from the bearing surface to the meplat. Comparators find a specific diameter on the bullet somewhere in the ogive that can be used to compare one bullet or one cartridge to another. Seating bullets in multiple steps may be good practice, but usually intended to minimize runout (turning the cartridge a bit between each seating step), and not to standardize seating depth. You may be experiencing the seating stem touching the meplat (so inconsistencies in the bullet point are showing up in differing seating depth). You are also using inconsistent brass so you may be seeing the result of variation in resistance to seating (interference between necks and bullet surfaces). Different brands of brass and even different lots of the same brand of brass can substantially vary in brass thickness and/or consistency of thickness around the neck. All can result in more or less resistance to seating forces and differences in final seating depth using the same tools.

Thanks Ya'll. We are sure happy with the happingings in DC today.

No not crushing powder. Got more room. ThanksJust a dumb question here…. Only trying to help. Are you crushing powder when seating your bullets? That’s the only time in my limited experience that I’ve experienced such seating depth variation.

Good note, I check that. Rick

You sorting your bullets by BTO?

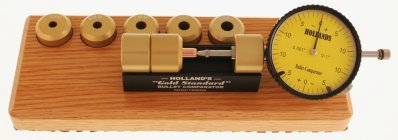

What I use......I did change to a wide flat tip to register on the base.

Some bullet bases have a slight concave and will give erratic readings

with a pointed tip. The unit does come with one and find it handy when

checking rim thickness on 22 rimfires.

Attachments

How clean is your brass? I find more base to ogive length variations with really clean necks. New brass with tight clean necks gives wild results at times. I prefer a little carbon in the neck for this reason.

Wild Bill IV

Gold $$ Contributor

USE THE MICROMETER FOR SEATING EVERY BULLET!! IT IS DESIGNED FOR THAT PURPOSE!!!Good Question. I'm using the Seating Micrometer Die that came in the kit. I assumed it would be OPK. And using Berger 95 grain projectiles.

Run the Mic up 0.010" (Ogive to bullet tip steam contact can vary 0.001"-0.005"/100 bullets), seat a bullet without rotating (sleeve seating dies align the case and the bullet, no need to rotate). Use the comparator to measure the CBTO (Cartridge base to Ogive). Adjust the Mic down to the desired calculated seating depth. Reseat the bullet and measure the CBTO again to confirm proper seating depth! My goal is to seat 0.002" to 0.003 off the lands (jump). I chase the lands!!

I use the Forster Mic Seating dies that also use the case alignment spring sleeves. When using sleeved seating dies, especially the dies with the sleeve protruding past the die body, NEVER bottom that sleeve out in the cam over or you could damage the sleeve, spring, and/or die body!!! Damaged dies can cause seating depth variation and/or bullet alignment problems!!! When in doubt, adjust the die body up to avoid damage to expensive seating dies!!!!

Last edited:

Do you have the REDDING VLD bullet seating stem installed in your seater die? Also the variance you are seeing MAY be caused by the meplat of the bullet contacting the bottom of the bullet seater stem cavity.Good Question. I'm using the Seating Micrometer Die that came in the kit. I assumed it would be OPK. And using Berger 95 grain projectiles.

I've been shooting this fine dual purpose hunting cartridge for over 50+ years. I have own a wide range of rifle brands in this caliber over this span of time.

You did say that this is a hunting rifle. My question is which critters are you hunting which relates to the vital area and thus accuracy required.

I never found it difficult, with some load development, to obtain sub-moa accuracy with the 243, even in factory sporter weight barrels. The powders I have used with considerable success are: IMR 4064, Varget, and IMR 4350, the latter with bullets over 85 grains. IMR 4895 can also be effective with lighter weight bullets.

I never found the seating depth to be a critical factor in accuracy in this cartridge. The two most influential factors in my experience regarding accuracy were the bullet and the powder selected. I never had a 243 Win that didn't shoot sub moa, and most well under sub moa with the 85 Sierra BTHP and IMR 4064 or Varget. This can serve as a dual-purpose hunting bullet, both for both deer* and varmint/predators.

As other have mentioned, you should start with virgin brass of the same brand and lot to maximize accuracy.

One of the most critical mechanical issues I found significantly affecting accuracy was the quality of bedding or the lack thereof. My Rem Model 7 would not shoot well until I replace the factory plastic stock with a B&C stock that has a bedding block.

*Eastern white tail deer.

You did say that this is a hunting rifle. My question is which critters are you hunting which relates to the vital area and thus accuracy required.

I never found it difficult, with some load development, to obtain sub-moa accuracy with the 243, even in factory sporter weight barrels. The powders I have used with considerable success are: IMR 4064, Varget, and IMR 4350, the latter with bullets over 85 grains. IMR 4895 can also be effective with lighter weight bullets.

I never found the seating depth to be a critical factor in accuracy in this cartridge. The two most influential factors in my experience regarding accuracy were the bullet and the powder selected. I never had a 243 Win that didn't shoot sub moa, and most well under sub moa with the 85 Sierra BTHP and IMR 4064 or Varget. This can serve as a dual-purpose hunting bullet, both for both deer* and varmint/predators.

As other have mentioned, you should start with virgin brass of the same brand and lot to maximize accuracy.

One of the most critical mechanical issues I found significantly affecting accuracy was the quality of bedding or the lack thereof. My Rem Model 7 would not shoot well until I replace the factory plastic stock with a B&C stock that has a bedding block.

*Eastern white tail deer.

memphistransplant

Gold $$ Contributor

Exactly how do you measure this distance?Also, I sort my bullets by BTO. . . BUT, the part of the ogive I sort by is where my seating stem touches the ogive.

Use your seater stem as a comparitorExactly how do you measure this distance?

With a comparator insert having a diameter where a light ring mark can be seen at the same place the seating stem does (like, twisting bullet slightly into the seating stem). Take a very small diameter comparator insert and drill out the hole to the size that matches the seating stem contact point. In the instance for my .264 bullets, the 17 calibers insert from Sinclair is a pretty good match for my L.E. Wilson seating die stem. Sorting bullets base to ogive with that insert.Exactly how do you measure this distance?

Last edited:

Rank Amateur

Gold $$ Contributor

Wikipedia: An ogive (/ˈoʊdʒaɪv/ OH-jyve) is the roundly tapered end of a two- or three-dimensional object. Ogive curves and surfaces are used in engineering, architecture, woodworking, and ballistics.Isn't the Ogive where the bullet meets the rifling? Anything forward of this point is the nose region.

Anything forward of the Ogive is meaningless in regards to pressure. .

Accurate Shooter link: https://bulletin.accurateshooter.co...y-tangent-secant-and-hybrid-ogives-explained/

Yes, the bullet meets the rifling somewhere along the ogive, but the ogive technically starts just ahead of the bearing surface and runs all the way to the meplat.

This horse might be really dead already but consistent neck tension is key. It’s not going to hurt anything to sort that out. As mentioned mixed brass equals inconsistent necks. Annealing helps but is not the only problem. Cheap brass has a lot of variations.

You need correct stem also though.

You need correct stem also though.

Alex Wheeler

Site $$ Sponsor

Take the die apart and remove the seater stem. Put a bullet in the stem and spin it. It will create a mark on the bullet where it contacts. If its touching the tip the bullet will feel loose and have play in the stem. Should be obvious. Its really hard to alter the front half of the bullet. If they are the same lot you will not see a lot of variation there. If your loading Bergers I dont think the stem seating up the ogive a little high is your issue. I have never gotten the best seating consistency on a regular press. When I used to use that style if press I would push extra hard at the bottom of the stroke to take out as much slop as possible. As a quick test give that a shot. I stopped annealing a long time ago and it has not hurt me in seating consistency. What does matter is you inside neck prep. Use a nylon brush and buff the inside of the neck or try the imperial graphite. Inside neck finish is 10 times more important than hardness when it comes to this. Even still I could never match an inline Wilson seater for consistency.This die has a sleeve that moves up when seating. I don't know how to tell where its hitting the bullet.

Similar threads

- Replies

- 26

- Views

- 2,757

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.