With a nut, the action ring is 'holding' the barrel (all directions, including shear).

A shoulder function is not actually needed here, provided you employ good and fine threading.

That is, you could key a barrel to the action ring, with no shoulder, and no nut (just keyed to prevent turning), and fire it just fine.

But it's an important function of the nut to set all threading in tension, which also prevents turning.

The direction of this tension is important to thread loading during firing (according to Harold Vaughn).

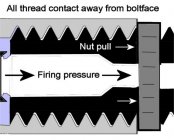

A nut pre-establishes connected threading in a static bias away from the bolt face, as it is during firing.

With this, the backside of all threading is engaged.

It is opposite of a shouldered connection, which actually unloads a bit during firing, because the first few threads pull later threads into little, no, or front side engagements(static). On firing those front side thread engagements then pull away from engagement.

Again, it's stud -vs- bolt.

View attachment 1386998

This reminds me that in my 60yrs, I have not seen bolt action firearms advance one bit.

There was always a

follow the leader basis for this & that,, and it never led anywhere.

Doesn't it seem odd, given better machining, better test equipment, computers?

We are truly stuck.