There is more than one kind of primer design in the Boxer world, and we still can see two or three foot anvils, and for unknown reasons they never come with installation instructions.

The lack of direct design information for primer installation baffles me cause it would take nothing to print it on the box or their websites. Be that as it may....

As someone who was formally indoctrinated in design development and testing of primers and initiators of many kinds, I will tell you all up front that the majority of the primers you find with an anvil foot that slightly protrudes from the cup is intended to be installed with a "crush" to those anvil feet of 0.002" - 0.006".

There are on occasion primers that have flush anvils, and those are to be inserted to bottom the cup.

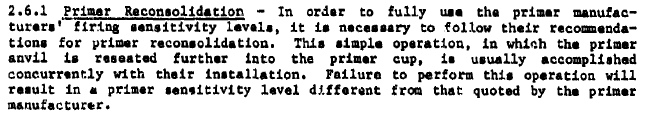

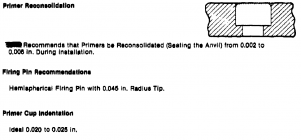

Here is a snippet of public domain specification that I am allowed to share as an example. What they are calling "reconsolidation" is what this forum often calls "crush".

View attachment 1608163

View attachment 1608168

When a device is added to measure the primer output performance, you can observe the consequences of not using the recommendations. The spread of the blast energy will not be as consistent as when installed to specs. The performance is not very sensitive once the anvils are touching, but they are improved by crush within their recommendations. So, don't expect to find a difference on the target for the difference between crush of 0.002" versus 0.006", but with enough of a sample you will find the difference of seated that accidentally leaves the anvil short of the bottom or just barely touching the bottom versus 0.002" - 0.006". YMMV