You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Induction brass annealer redux

- Thread starter Gina1

- Start date

Making progress. Still need to finish the hopper that will dispense to the top staging location but the initial PLC programming is done. Timers are a bit long for troubleshooting and I don't have power on the annealing coil yet.

I had to disconnect the S+ and S- wires from the power supply to the output of the annealing solenoid in order to see the annealing LED light. Seems there is 48vdc on those sensing terminals for the current limit function that makes the LED stay on all the time. Any ideas GrocMax? Is it normal to have 48vdc across pins 1 and 3 (S+ and S-)?

I had to disconnect the S+ and S- wires from the power supply to the output of the annealing solenoid in order to see the annealing LED light. Seems there is 48vdc on those sensing terminals for the current limit function that makes the LED stay on all the time. Any ideas GrocMax? Is it normal to have 48vdc across pins 1 and 3 (S+ and S-)?

I'll check tomorrow on mine. 2 and 4 are connected to V+ and V- internally, you left these floating with 1 and 3 connected to the load (ind. board) right? Mine is working properly, I ran a twisted pair from pin 1,3 direct to the ind board terminals with nothing else connected, so pin 1 and V+ at ind board are always connected, pin 3 and V- are open till the relay kicks on.

I see yours shows 48v with the relay/contactor off, I don't have an LED mine sits at 15v, using a SPST relay on the gnd leg, your diagram shows a DPST maybe that's the difference.

I never tried to hook up an LED I figured the ammeter was telling me status already.

If all else fails you can run the LED off the 120v contactor coil power with 2 diodes and a big resistor. Sorta inelegant and some higher heat dissipation than normal but it works.

I see yours shows 48v with the relay/contactor off, I don't have an LED mine sits at 15v, using a SPST relay on the gnd leg, your diagram shows a DPST maybe that's the difference.

I never tried to hook up an LED I figured the ammeter was telling me status already.

If all else fails you can run the LED off the 120v contactor coil power with 2 diodes and a big resistor. Sorta inelegant and some higher heat dissipation than normal but it works.

Last edited:

I'll check tomorrow on mine. 2 and 4 are connected to V+ and V- internally, you left these floating with 1 and 3 connected to the load (ind. board) right? Mine is working properly, I ran a twisted pair from pin 1,3 direct to the ind board terminals with nothing else connected, so pin 1 and V+ at ind board are always connected, pin 3 and V- are open till the relay kicks on.

I see yours shows 48v with the relay/contactor off, I don't have an LED mine sits at 15v, using a SPST relay on the gnd leg, your diagram shows a DPST maybe that's the difference.

I never tried to hook up an LED I figured the ammeter was telling me status already.

If all else fails you can run the LED off the 120v contactor coil power with 2 diodes and a big resistor. Sorta inelegant and some higher heat dissipation than normal but it works.

I connected the inductor board (power supply load) and reconnected the S+ and S- wires this morning and the power supply produces no output :-(

I wonder if connecting the V+ and V- would make a difference; even though the spec sheet says you don't need them when not using voltage trim? Checked my current limit pot and it's sending 3.5VDC to 5.0VDC to pin 7. I've also left pin 11 floating as you mentioned in a previous post.

Do you mean +VS and -VS? I left them open when +S and -S were hooked to the load. Its possible the +S/-S won't work in your case with the DPST cutting off both V+ and V- from the sense lines, try them looped +VS to +S, -VS to -S and see if it comes back to life. If it knows its on but it sees zero voltage on the +S maybe it goes into fault? The load voltage sense really isn't necessary anyways, we're using short load wires of big enough gauge not to have significant drops.

I do know in order for it to output you need 13 and 14 looped, 5 and 6 looped (voltage control), at least 2v to the current control pin 7. If it goes into fault the PS status LED goes from green to red and I see 5v on the voltmeter. Things that will trip a fault are under voltage (~5v) or too low of a voltage limit or current limit control voltage (below 2v), over voltage (~55v) and over current (over 20A). In order to recover from a fault condition you have to switch it off for long enough to discharge the caps, a momentary switch off it won't recover.

I do know in order for it to output you need 13 and 14 looped, 5 and 6 looped (voltage control), at least 2v to the current control pin 7. If it goes into fault the PS status LED goes from green to red and I see 5v on the voltmeter. Things that will trip a fault are under voltage (~5v) or too low of a voltage limit or current limit control voltage (below 2v), over voltage (~55v) and over current (over 20A). In order to recover from a fault condition you have to switch it off for long enough to discharge the caps, a momentary switch off it won't recover.

Last edited:

Do you mean +VS and -VS? I left them open when +S and -S we hooked to the load. Its possible the +S/-S won't work in your case with the DPST cutting off both V+ and V- from the sense lines, try them looped +VS to +S, -VS to -S and see if it comes back to life. If it knows its on but it sees zero voltage on the +S maybe it goes into fault? The load voltage sense really isn't necessary anyways, we're using short load wires of big enough gauge not to have significant drops.

I do know in order for it to output you need 13 and 14 looped, 5 and 6 looped (voltage control), at least 2v to the current control pin 7. If it goes into fault the PS status LED goes from green to red and I see 5v on the voltmeter. Things that will trip a fault are under voltage (~5v) or too low of a voltage limit or current limit control voltage (below 2v), over voltage (~55v) and over current (over 20A). In order to recover from a fault condition you have to switch it off for long enough to discharge the caps, a momentary switch off it won't recover.

Yes, I meant +VS and -VS. I went back to factory default loops and it works fine. 1-2, 3-4, 5-6, 7-8 and 13-14. You may be right; might be the DPST cutting off both + and - to the S+ and S- pins. I'll need to play with it a bit. In the meantime, at least it's working! 6.25 seconds hits about right with my 750 degrees templaq and only pulling about 12.6 amps

Cool. Next step current control!

Fixed the problem. Super easy. Just had to move the S+ and S- connections to input of the DPST relay instead of the output. This gives the power supply a solid voltage reference prior to annealing and will still sense the load when the contacts close and annealing is taking place. Also solves the issue of the annealing LED illuminating early!

I'll post new electrical drawing after I update with my "as built"

Next challenge...finish my feed hopper! Gotta love the journey

Need help......

Finished the coolant loop so finally fired up the induction board for the first time.

Before i could even see what went on i blew the fuse on the low voltage side.

Replaced with a time delay fuse and fired up again with an empty coil.

In a few seconds i blew the second fuse but this time i could see what happened.

So my setup for who did not follow my build :

*Powered by two microwave oven transformers with primaries in series and rewound secondaries (14ga wire), also in series with an output of about 40 vdc after the rectifier.

(I used two transformer both with only 60v input so they would not run hot)

*Va meter with unit on (no power to induction board) reads v=41 a=0.35

*The bridge rectifier used is a GBJ2506 600v (25a salvaged from an induction microwave)

So when the relay switches power to the induction board the voltage droped quickly to about 6 volt and the amps ramped up to over 40a.

then the fuse popped..

What is going on?

I knew that voltage would drop with load applied but this much??I did not even have brass in the coil..

Did i fry the board also? (The ebay add says 20a max.)

Thanks in advance,

Bert

Finished the coolant loop so finally fired up the induction board for the first time.

Before i could even see what went on i blew the fuse on the low voltage side.

Replaced with a time delay fuse and fired up again with an empty coil.

In a few seconds i blew the second fuse but this time i could see what happened.

So my setup for who did not follow my build :

*Powered by two microwave oven transformers with primaries in series and rewound secondaries (14ga wire), also in series with an output of about 40 vdc after the rectifier.

(I used two transformer both with only 60v input so they would not run hot)

*Va meter with unit on (no power to induction board) reads v=41 a=0.35

*The bridge rectifier used is a GBJ2506 600v (25a salvaged from an induction microwave)

So when the relay switches power to the induction board the voltage droped quickly to about 6 volt and the amps ramped up to over 40a.

then the fuse popped..

What is going on?

I knew that voltage would drop with load applied but this much??I did not even have brass in the coil..

Did i fry the board also? (The ebay add says 20a max.)

Thanks in advance,

Bert

Last edited:

Hi Bert,Need help......

Finished the coolant loop so finally fired up the induction board for the first time.

Before i could even see what went on i blew the fuse on the low voltage side.

Replaced with a time delay fuse and fired up again with an empty coil.

In a few seconds i blew the second fuse but this time i could see what happened.

So my setup for who did not follow my build :

*Powered by two microwave oven transformers with primaries in series and rewound secondaries, also in series with an output of about 40 vdc after the rectifier

*Va meter with unit on (no power to induction board) reads v=41 a=0.35

So when the relay switches power to the induction board the voltage drops quickly to about 6 volt and the amps ramp up to over 40a.

then the fuse popped..

What is going on?

I knew that voltage would drop with load applied but this much??I did not even have brass in the coil..

Did i fry the board also? (The ebay add says 20a max.)

Thanks in advance,

Bert

Sounds like a short to ground or possibly your coils are touching; though I'm not sure coils touching would create the short to ground symptoms. Might check for stray metal bits or solder from your build.

Hi Bert,

Sounds like a short to ground or possibly your coils are touching; though I'm not sure coils touching would create the short to ground symptoms. Might check for stray metal bits or solder from your build.

Thanks I will go over that.

However I'm sure the coils are not touching. The coil also has a few coats of dolphs ac-46 circuit board varnish on it and I also put shrink tube over the one coil "leg" so it could not accidentally touch the terminal of the other coil leg.

Without a wiring diagram I wouldn't even want to guess, besides I think AC is magic and doesn't really exist

Possibly a bad or backwards diode in the rectifier section?

I'll see if I can make a wiring diagram.

The rectifier is a one piece thing so don't think something is backwards there.

If I put the multimeter on the diode output I get the 40v dc.

Don't know if this helps with trouble shooting but I just

disconnected the induction board and hooked up a regular 60w light bulb instead.

Ran the cycle and got the following meter readings;

unit on standby: 40.7v 0.38a

bulb on: 39.9v 0.63a

Just a wonder.

If the control relay is wired to power the transformer, power source or whatever, it won't work.

The control relay must be after the DC power source.

In other words, the power supply to the induction board must be up and running at the time of connection.

My two cents.

Fixed the problem. Super easy. Just had to move the S+ and S- connections to input of the DPST relay instead of the output. This gives the power supply a solid voltage reference prior to annealing and will still sense the load when the contacts close and annealing is taking place. Also solves the issue of the annealing LED illuminating early!

I'll post new electrical drawing after I update with my "as built"

Next challenge...finish my feed hopper! Gotta love the journey

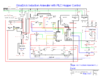

Here's the updated drawing per my "as built". PM me if you'd like the TinyCad file. I'm also working the final parts list and can include that when complete. Still working on the hopper; need to machine a few parts on my mini CNC.

Just a wonder.

If the control relay is wired to power the transformer, power source or whatever, it won't work.

The control relay must be after the DC power source.

In other words, the power supply to the induction board must be up and running at the time of connection.

My two cents.

No the relay switches the 40vdc power, so after the transformer and bridge rectifier.

Here's the updated drawing per my "as built". PM me if you'd like the TinyCad file. I'm also working the final parts list and can include that when complete. Still working on the hopper; need to machine a few parts on my mini CNC.

View attachment 1001018

OH my gosh !!!!!! Sheeeeeesh..... I'm looking at your drawing, just shaking my head. How the GinaErick has grown. The talent that is out there is unreal. My hat is off to all you inventors/ innovators.

David... anyway to get a picture of your "mini" CNC ? sounds interesting

OH my gosh !!!!!! Sheeeeeesh..... I'm looking at your drawing, just shaking my head. How the GinaErick has grown. The talent that is out there is unreal. My hat is off to all you inventors/ innovators.

David... anyway to get a picture of your "mini" CNC ? sounds interesting

It's a Nomad 883Pro from http://carbide3d.com

Similar threads

- Replies

- 74

- Views

- 47,427

- Replies

- 0

- Views

- 1,578

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.