Hmmm??? Comparing that university study that used much thicker brass in their study to what goes on with the thin brass of case necks is like comparing apples and oranges. 1050°F for a minute on a case neck is very different from what they were doing at that university.I know what you mean the end of the case mouth gets red first. I ignore it and just go for the bulk of the neck. A couple seconds hotter at the case mouth shouldn't change the amount of annealing. It takes over a minute at about 1050F to see a very small change in hardness based on the Univerity of Ill charts.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Induction Annealing Results With Tempilaq

- Thread starter Bidwell

- Start date

Got it, scary. OK I'll wait till the thinner gets here and try it again. So far the 450 paint melts a little over a quarter inch past the neck junction so i think I should be ok.The higher tempilaq is probably burning because it is too thick.

It should be like water when applying, then let it dry completely.

A case that has been annealed in the web area will cause a catastrophic failure .... as in boom, explosion catastrophic.

Use the 450 as an indicator. Paint it down the side of the case to see how far down the case you are heating up.

IMO ... the heat should not go very far past the neck shoulder junction.

Understood, appreciate it!I know what you mean the end of the case mouth gets red first. I ignore it and just go for the bulk of the neck. A couple seconds hotter at the case mouth shouldn't change the amount of annealing. It takes over a minute at about 1050F to see a very small change in hardness based on the Univerity of Ill charts.

Templaq is never supposed to be used with a flame directly on it. A thick coat may act as an insulator. The case may be 1000F on one side of the Templiq and 2000Fon the other side of the Templaq. Garbage results.The higher tempilaq is probably burning because it is too thick.

It should be like water when applying, then let it dry completely.

A case that has been annealed in the web area will cause a catastrophic failure .... as in boom, explosion catastrophic.

Use the 450 as an indicator. Paint it down the side of the case to see how far down the case you are heating up.

IMO ... the heat should not go very far past the neck shoulder junction.

Last edited:

If you heat till red for 1-2 seconds and stop you cannot over heat the case body. Your wasting money on Templaq.Thanks! I'll probably order some thinner and give it a shot

You miss the point, if it doesn't anneal in one minute or 5 minutes it cannot anneal in a fraction of a second. It's time at temperature it shouldn't matter how thick it is. I understand it isn't flash annealing. The charts show it shouldn't be possible to over anneal or damage the case body or head if you stop when the neck just turns red.Hmmm??? Comparing that university study that used much thicker brass in their study to what goes on with the thin brass of case necks is like comparing apples and oranges. 1050°F for a minute on a case neck is very different from what they were doing at that university.Like, it takes longer for a larger amount of mass to absorb heat/energy than a lesser mass when exposed to a given temperature/energy. I'm sure you must know that. So, I don't know why you're reference the times from that study to our annealing case???¯\_(ツ)_/¯

The plates were about 13/16" thick and rolled to produce different cold work and annealed in a lead bath not a furnace as I first thought. The heating rate was measured and very rapid.

Last edited:

TTE

Gold $$ Contributor

Mentioned 'paint down the side' because that is easier than trying to start in a precise place on the case (out of the flame)Templaq is never supposed to be used with a flame directly on it. A thick coat may act as an insulator. The case may be 1000F on one side of the Templiq and 2000Fon the other side of the Templaq.

Pretty sure you know more than me on this subject, but I'm guessing a stripe of 450 down the side of the case will show where there is + 450 degrees on the case and where it isn't.

I don't think you need to worry about over heating the body. To soften the body it would have to be over something like 800-900F for minutes to lose just a couple hardness numbers.Mentioned 'paint down the side' because that is easier than trying to start in a precise place on the case (out of the flame)

Pretty sure you know more than me on this subject, but I'm guessing a stripe of 450 down the side of the case will show where there is + 450 degrees on the case and where it isn't.

TTE

Gold $$ Contributor

In my case it's Murphy's law. (and in some things I am from Missouri, .... I'm not .... but I am).I don't think you need to worry about over heating the body. To soften the body it would have to be over something like 800-900F for minutes to lose just a couple hardness numbers.

I have Tempilaq, so will use it at least until I run out.

Last edited:

Templaq is never supposed to be used with a flame directly on it. A thick coat may act as an insulator. The case may be 1000F on one side of the Templiq and 2000Fon the other

I contacted McMaster-Car and there sending me some new tempilaq for the 750 and 1000f paint, no charge. The viscosity is like tomato soup. They said they'd check the viscosity before shipping this time, the support there is great. From what I'm reading, this stuff is sort of notorious for drying out and going bad (at least for some temp versions). I did get the thinner, will be here tomorrow so I'll try that too. If it works I guess I doubled up on tempilaq. Sounds like you can get by without the tempilaq from what other posts are saying but I guess I've already made the investment and it seems useful for educational purposes at the very least.The higher tempilaq is probably burning because it is too thick.

It should be like water when applying, then let it dry completely.

A case that has been annealed in the web area will cause a catastrophic failure .... as in boom, explosion catastrophic.

Use the 450 as an indicator. Paint it down the side of the case to see how far down the case you are heating up.

IMO ... the heat should not go very far past the neck shoulder junction.

Mentioned 'paint down the side' because that is easier than trying to start in a precise place on the case (out of the flame)

Pretty sure you know more than me on this subject, but I'm guessing a stripe of 450 down the side of the case will show where there is + 450 degrees on the case and where it i

450F is a made up number to look for over heating. The body could probably be at least 700F for a few seconds without softening the brass. You cannot use 1000F Templaq with a flame on it. Just heat till you see the beginning of red and maybe 1 or 2 seconds more and you have done about the best that's possible and you are not over heating the body or head.The higher tempilaq is probably burning because it is too thick.

It should be like water when applying, then let it dry completely.

A case that has been annealed in the web area will cause a catastrophic failure .... as in boom, explosion catastrophic.

Use the 450 as an indicator. Paint it down the side of the case to see how far down the case you are heating up.

IMO ... the heat should not go very far past the neck shoulder junction.

I think 450F was chosen because that's a typical temp maybr a 1/2" below the shoulder with normal annealing temp. Someone put a nice pix on this website rececently with his 450F stripe after annealing. 450F only went about 1/2" below the shoulder. Cannot find the PIX.

Last edited:

That's about what I'm at right now with the 450, or a little less. The 750 starts turning black or melting at about the shoulder to body junction and the 1000f just barely starts melting at the tip of the case450F is a made up number to look for over heating. The body could probably be at least 700F for a few seconds without softening the brass. You cannot use 1000F Templaq with a flame on it. Just heat till you see the beginning of red and maybe 1 or 2 seconds more and you have done about the best that's possible and you are not over heating the body or head.

I think 450F was chosen because that's a typical temp maybr a 1/2" below the shoulder with normal annealing temp. Someone put a nice pix on this website rececently with his 450F stripe after annealing. 450F only went about 1/2" below the shoulder. Cannot find the PIX.

Sure is. Wish there was an affordable way to quantify the hardness. I was thinking about getting an arbor press and force gauge to see if I can get close to factory seating pressure. I've also looked into getting a knock off hardness tester. I just want to mimick new factory brass as closely as possible.Lots of discussion regarding this in the

Induction brass annealer redux

thread. At the end of the day it's all a guess without a process to accurately measure brass hardness pre and post annealing. Even then, what's an appropriate hardness? Good luck.

Likewise, I wanted to get my annealing close to what we see in factory brass and that's why I decided to get one of those "knock off hardness testers". I'm very satisfied with what I found to where I can get much closer to that goal that all the previous guessing.Sure is. Wish there was an affordable way to quantify the hardness. I was thinking about getting an arbor press and force gauge to see if I can get close to factory seating pressure. I've also looked into getting a knock off hardness tester. I just want to mimick new factory brass as closely as possible.

Flame Annealing - almost perfect

As I mentioned in another thread, I recently bought a Webster Hardness Tester (it's a counterfeit) to get a better idea of what my annealing efforts were actually like. Am reporting back with what I've observed after doing some testing to see how this tester might help. It's always been my...

forum.accurateshooter.com

Sure is. Wish there was an affordable way to quantify the hardness. I was thinking about getting an arbor press and force gauge to see if I can get close to factory seating pressure. I've also looked into getting a knock off hardness tester. I just want to mimick new factory brass as closely as possibleLots of discussion regarding this in the

Induction brass annealer redux

thread. At the end of the day it's all a guess without a process to accurately measure brass hardness pre and post annealing. Even then, what's an appropriate hardness? Good luck.

Thanks for the post! That thread is very useful. Thats interesting that you slightly over shot the annealing to get to the correct hardness after resizing. I've seen some of the cheap hardness testers on aliexpress and some on ebay. We'll see, definitely tempting. I also sent a message to lapua to see if they would provide any temperature and time duration numbers about their annealing process. I get the feeling they won't provide that info but might as well ask. Thanks again.Likewise, I wanted to get my annealing close to what we see in factory brass and that's why I decided to get one of those "knock off hardness testers". I'm very satisfied with what I found to where I can get much closer to that goal that all the previous guessing.

Flame Annealing - almost perfect

As I mentioned in another thread, I recently bought a Webster Hardness Tester (it's a counterfeit) to get a better idea of what my annealing efforts were actually like. Am reporting back with what I've observed after doing some testing to see how this tester might help. It's always been my...forum.accurateshooter.com

I wasn't thinking about this quite right I think? The difference in severity between a case head separation and the explosion from an over annealed case is that the pressure is still released by the bullet exiting the case in a case head separation, while in an over annealed case the case explodes without the bullet leaving the casing, therefore the explosion doesnt have an open barrel to release the pressure? Or is that still off base?The higher tempilaq is probably burning because it is too thick.

It should be like water when applying, then let it dry completely.

A case that has been annealed in the web area will cause a catastrophic failure .... as in boom, explosion catastrophic.

Use the 450 as an indicator. Paint it down the side of the case to see how far down the case you are heating up.

IMO ... the heat should not go very far past the neck shoulder junction.

I wasn't thinking about this quite right I think? The difference in severity between a case head separation and the explosion from an over annealed case is that the pressure is still released by the bullet exiting the case in a case head separation, while in an over annealed case the case explodes without the bullet leaving the casing, therefore the explosion doesnt have an open barrel to release the pressure? Or is that still off base?

Based on my chart you have to be at 1100F for about 15 seconds before you start getting serious loss of hardness. I don't see how you can soften the body and head unless you do something stupid. AMPS has hardness data on case bodies and heads for annealed cases. They don't give time at temp but the heads never show a loss of hardness.

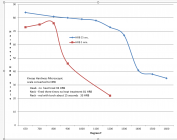

My annealing study with Lapua necks in a lab quality furnace for 15 seconds and 5 minutes. I chose 15 seconds because I had no idea how long it would take to get to temp. If the hardness shows almost no change in 15 seconds it cannot change by flash annealing for a fraction of a second at temp. This is about the 5th. time I put this chart on the website. A Lapua case fired 3 times and never annealed had a neck hardness of 81 HRB for comparision.

You don't have to match the factory neck hardness. The factory anneals so they can severely deform a coin like disc into a cartridge case. The factories all say they don't suggest reloading the cases. I think this is just Lawyer talk to protect them from law suites. Good common sense for the manufacturer. I think it's a waste of time buying a hardness tester. Would a hardness tester tell you you have to go beyond red for more than a couple seconds.?

15 seconds at 900F constant temp the neck lost only a couple hardness units. The first data point at 650F looks a little higher than the new unannealed case? Normal variation? Each data point in the chart was the average of 3 microhardness indents.

Last edited:

Thanks for providing this. Apologies if these are dump questions:My annealing study with Lapua necks in a lab quality furnace for 15 seconds and 5 minutes. I chose 15 seconds because I had no idea how long it would take to get to temp.

If the hardness shows almost no change in 15 seconds it cannot change flash annealing for a fraction of a second at temp. This is about the 5th. time I put this chart on the website. A Lapua case fired 3 times and never annealed had a neck hardness of 81 HRB for comparision.

You don't have to match the factory neck hardness. The factory anneals so they can severely deform a coin like disc into a cartridge case. The factories all say they don't suggest reloading the cases. I think this is just Lawyer talk to protect them from law suites. Good common sense for the manufacturer. I think it's a waste of time buying a hardness tester. Would a hardness tester tell you you have to go beyond red for more than a couple seconds.?

15 seconds at 900F constant temp the neck lost only a couple hardness units. The first data point at 650F looks a little higher than the new unannealed case? Normal variation? Each data point in the chart was the average of 3 microhardness indents.

View attachment 1613132

1. Does it matter that the annealing was done on a case fired 3 times? In other words, does it take more time to anneal at a given temp on a case fired 3 or 4 times than a case fired once? Is annealing time not appreciably effected by previous hardness level?

2. From your other posts, you recommended getting the neck to just turn red, then add one or two seconds past that. Do you think there's any correlation to a data point on this chart even though the typical anneal time is much shorter than 15 seconds?

I'm just going with the "neck gets red" method for now and adding a second. With this, the 750 Tempilaq melts just past the shoulder/body junction, the 1000f melts about 80% of the distance of the case neck to the shoulder and the 450 melts 3/8 of an inch down from the shoulder into the body. Seems this is in the ballpark so I guess it's time to just start reloading and see how it goes.

Cold working puts stress (energy) into the brass. The amount of cold work slightly raises how fast it anneals. People are making a big deal out of annealing. Annealing may not show improvement on the target, but it will increase case life. My rifles are for GH hunting and they easily shoot under 0.400" groups. I have shot a few groups in the 1s. Maybe 1 out of 25 groups is 0.250" or smaller. I cannot shoot consistantly small groups to tell if annealing helps group size or consistancy. I don't use wind flags. I don't measure true group size I have always measured vertical and horiziontal size. After shooting 1000s of groups I see a clear trend that my groups are 0.100" wider than tall. I assume it's wind.Thanks for providing this. Apologies if these are dump questions:

1. Does it matter that the annealing was done on a case fired 3 times? In other words, does it take more time to anneal at a given temp on a case fired 3 or 4 times than a case fired once? Is annealing time not appreciably effected by previous hardness level?

2. From your other posts, you recommended getting the neck to just turn red, then add one or two seconds past that. Do you think there's any correlation to a data point on this chart even though the typical anneal time is much shorter than 15 seconds?

I'm just going with the "neck gets red" method for now and adding a second. With this, the 750 Tempilaq melts just past the shoulder/body junction, the 1000f melts about 80% of the distance of the case neck to the shoulder and the 450 melts 3/8 of an inch down from the shoulder into the body. Seems this is in the ballpark so I guess it's time to just start reloading and see how it goes.

Similar threads

- Replies

- 32

- Views

- 2,090

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.