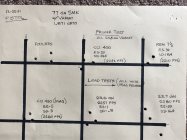

While I have been able to get my extreme spread in muzzle velocity below 20 fps in most other calibers I can’t seem to do the same with my .223s that I use for PRS style competition Using a bolt action rifle. I use all the same tricks (weighing the powder to +/- .02 grain, lubing the case mouths, uniform case neck tension of .003”, uniform case weight, primer pockets, yada yada yada) but my “good” ESs are around 40 fps. Always measured on the same MagnetoSpeed chrono. I’m using 77 grain Sierra MKs with H4895 and CCI BR4s. I have also tried Varget, RL15, and CFE223.

At 100 yards the rifle pretty consistently shoots 0.4 to 0.6” groups.

What are you guys getting with your .223s? One the distances go over 700 yards the elevation gets a little sketchy.

Thanks

I have danced around the 223 precision camp fire for many years and gone down the rabbit hole far enough to reach what I believe to be the very end. I'll share with you what I have concluded...

BTW, I do not care about tactical division bullet or velocity restrictions... Just shoot in open division.

We can hit 2900 FPS with 90 grainers as long as your throat is long enough. I run 88 ELDMs and 90 Atips seated to touch the lands just under 2.700"... Yes 2.700"

Why seated out so far you might ask... Well 2 reasons.. it maximizes powder capacity so we can maximize velocity with reasonable pressures. The long seating depth equals long throat and if it is not effed up and oversize, thats a big IF BTW... the throat will align those long fussy high BC rounds so they start into the rifling nice and straight. If the throat is small enough.. just minimally clear of the bullet diameter, you will have no trouble holding 1/4 MOA at 100 yards.

BTW, if the throat is snug enough, it will help dramatically to reduce your velocity spreads because the bullet will not be canted off on an angle like it would be with a sloppy free bore.

I have gone to great lengths in my chambering efforts to control my freebore diameter using a throating reamer and a conical bushing that aligns the reamer in the bolt nose clearance hole.

This brings us to our next problem... Finding a 223 mag that will allow you to feed rounds of 2.700 long... Well Accurate Mag and MDT both make metal mags with 2 piece plastic inserts that can be modified using a little JB Weld and some milling.

As for my brass... I no longer bother with Lapua... I use IVI but I would prefer Lake City if I can get it. I buy once fired brass in quantities of at least 3000, and I process all of it including anneal. Once complete I weigh every case and write the weight on the case with a sharpie. Once complete, I sort all the cases into lots that are identical in weight within 1/10th grain.

I weigh my powder using a Vibra HT220 scale because it can weigh to 1/10th of the weight of a singe kernel of Varget... Yes cut one kernel into 10 pieces and it will detect it. The small 223 powder capacity requires more precise powder weights than cases with greater powder capacity.

With fire formed cases this recipe will produce velocity spreads that rarely exceed 10 FPS.

Anyway, it works well for me and I dont believe I will every change anything at this point except possibly some newfangled bullet one day.