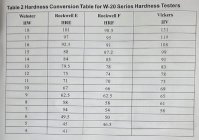

Finally got together with my shooting buddy who has an AMP annealer to test what my hardness tester shows after a case has been anneal with the AMP. As a reminder, my goal is to have my cases at the same hardness when finished with sizing as the hardness of my virgin Lapua cases (as reading on this tool of 15). So, we took a case and sacrificed it to get the AMP's code, per AMP's instructions. Set the code and annealed 3 cases. Cleaned off the oxidation layer with some steel wool, ran a bore brush through the necks too and then measured the hardness. As I suspected, the hardness showed all three of them being right at 15. Great, huh? The problem is, we now have to size the cases, which will increase the hardness to 17 on this tool.

I guess 17 is not necessarily "bad", especially if it's consistent. My old flame annealing approach where I'd just drop the case out of the flame when the flame started to turn orange would essentially get me the same results (17 after the sizing process). To get my necks to the 15 hardness reading I have to anneal them to where I get a 13 reading and the sizing bring them back up to my target of 15.

Apparently, if one is using a AMP machine, one will have to customize a code to anneal the cases more than the code that's produced so that the sizing brings the hardness to that 15 reading I get on virgin Lapua brass.

Just thought I'd share this to show what the AMP machine is doing in comparison to what I've been doing with my flame annealing process.

I guess 17 is not necessarily "bad", especially if it's consistent. My old flame annealing approach where I'd just drop the case out of the flame when the flame started to turn orange would essentially get me the same results (17 after the sizing process). To get my necks to the 15 hardness reading I have to anneal them to where I get a 13 reading and the sizing bring them back up to my target of 15.

Apparently, if one is using a AMP machine, one will have to customize a code to anneal the cases more than the code that's produced so that the sizing brings the hardness to that 15 reading I get on virgin Lapua brass.

Just thought I'd share this to show what the AMP machine is doing in comparison to what I've been doing with my flame annealing process.

Last edited: