People keep putting made up numbers on this website.Hmmm??? 250°C/480°F for how long?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flame Annealing - almost perfect

- Thread starter Straightshooter1

- Start date

Nice info.The one good place to use Tempilaq in teaching neck annealing was to demonstrate to the students how the heat propagates down the case body. (That is also a back-handed way of saying the internet lore of using the 750F on the necks is not a good method.)

By painting a stripe of 400F Tempilaq down the case body and then running it through the process, the trainees got to see how far down the body the 400F line would go.

Generally, even when using a relatively "slow" flame annealing time, the 400F goes roughly a body diameter below the body-shoulder junction, and less when regular rates were used.

If you noticed the "patina" created on Straighshooter1's brass photos, somewhere about the end of that patina is where the 400F level would be seen. This level is way above the level where the case body tends to fail due to stretching. YMMV

View attachment 1609198

Jim,We have member that I believe works with Capstone, he might shed some light on Lapua’s annealing process. Maybe @barefooter56 will weigh in.

A question for Straightshooter1~ what is the end result you are seeking ?

Is it sizing consistency or bullet seating consistency or both and how are you confirming the results ?

Thx for testing and sharing.

Jim

Annealing info is proprietary and cannot be given out. The only info is that LAPUA cases are produced with longevity in mind and they do not recommend re- annealing of their cartridge cases due to possibly ruining the cartridge case through over or under annealing.

Thought some of you might find this of interest:

I just happened to come across this YouTube video where the guy actual had some Vickers hardness testing done for his test. Like I found in my less precise hardness testing, he found substantial increase in hardness after sizing. But like he mentioned, how much the necks are worked (reduced then expanded again) will vary the amount of increase in hardness after the annealing process. He doesn't say what he's using for his annealing process, but given the short periods of time, I'd bet it's done with an induction annealer.

I just happened to come across this YouTube video where the guy actual had some Vickers hardness testing done for his test. Like I found in my less precise hardness testing, he found substantial increase in hardness after sizing. But like he mentioned, how much the necks are worked (reduced then expanded again) will vary the amount of increase in hardness after the annealing process. He doesn't say what he's using for his annealing process, but given the short periods of time, I'd bet it's done with an induction annealer.

Last edited:

RegionRat

Gold $$ Contributor

Here are two screen captures from his video.

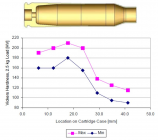

The first shows a survey of microhardness (HV) down the case. The takeaway is that his process doesn't go too far down the body or shoulder, and also that his neck sizing re-hardens the necks.

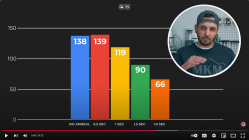

The second screen shot shows his process time. His annealer is running at a relatively high power (heat-rate) compared to some folks (that makes it time sensitive), and he mentions that the data point at HV = 90 is near the Draper Point, which is advice folks have heard around here somewhere.

It also shows that if you dwell there too long, you can drop the hardness well below the nominal target of HV=95, and further that when you cold work by sizing, the hardness recovers.

Merry Christmas and Happy New Year!!!

The first shows a survey of microhardness (HV) down the case. The takeaway is that his process doesn't go too far down the body or shoulder, and also that his neck sizing re-hardens the necks.

The second screen shot shows his process time. His annealer is running at a relatively high power (heat-rate) compared to some folks (that makes it time sensitive), and he mentions that the data point at HV = 90 is near the Draper Point, which is advice folks have heard around here somewhere.

It also shows that if you dwell there too long, you can drop the hardness well below the nominal target of HV=95, and further that when you cold work by sizing, the hardness recovers.

Merry Christmas and Happy New Year!!!

The plot looks like the length of the indent plotted and not the VHN? At least he gave the load on the indenter it's an ASTM requirement. What's max and min. mean.When he suspected the hardness value of a piece of virgin factory brass was HV = 95, he wasn't wrong.

It just took some time to get him up to speed.

For your background, here is a public domain version of a M855 case.

View attachment 1615622

Merry Christmas and Happy New Year!!!

You cannot perform microhardess with a 2.5 kg. load on the indenter with thin sheet metal. A 500 gram load is standard in the specs. for almost all materials and you might have to go lower based on the thickness and hardness of the metal. I wish I had an ASTM conversion chart in front of me so I don't say something stupid. Been retired for 11 years.

Based on the hardness numbers he must be over 1200F for a fraction of a second.Thought some of you might find this of interest:

I just happened to come across this YouTube video where the where the guy actual had some Vickers hardness testing done for his test. Like I found in my less precise hardness testing, he found substantial increase in hardness after sizing. But like he mentioned, how much the necks are worked (reduced then expanded again) will vary the amount of increase in hardness after the annealing process. He doesn't say what he's using for his annealing process, but given the short periods of time, I'd bet it's done with an induction annealer.

There's a couple other interesting tests that have been done that I feel can also clarify a lot of questions about temperature, hardness and what it might take to get what we want from our annealing processes. There's the Ryan Stevenson study from the University of Stathclyde in Scotland (attached is the PDF file report).

There's this detailed report on a salt bath test, which Rocketvapor has posted before, using various temperatures and the resulting hardness testing:

There's this detailed report on a salt bath test, which Rocketvapor has posted before, using various temperatures and the resulting hardness testing:

Annealing Temperatures For Reloading Brass Cartridge Cases

G. Chambers, Ballistic Recreations Introduction Although the metallurgy of brass has been extensively studied and understanding is quite advanced at the academic and industrial levels, technical kn…

ballisticrecreations.ca

Attachments

This thread is somewhat timely as I recently annealed fifty cases after 10 times sized and fired, now that I have a decent history with these cases I should be able to collect some quality data. My interest are mainly on target improvements or decline although I will take some notes as to sizing and seating.

I don’t wish to distract from @Straightshooter1 so I may start another thread or just hold onto my notes for reference, haven’t decided yet but here’s a sample of the cases.

I don’t wish to distract from @Straightshooter1 so I may start another thread or just hold onto my notes for reference, haven’t decided yet but here’s a sample of the cases.

Attachments

Pareto

Silver $$ Contributor

I'm just now getting to this thread, but it is fascinating to me because it seems like it is hard to over anneal and not be able to reharden just by resizing. However, I managed to anneal about 20 pieces of brass, half Lapua and half Norma that were so soft that a bullet couldn't be held firmly in place, even after 2 or 3 resizings. I now keep them around to test for glow when setting up my annealer's timing, cause otherwise they're garbage. Aside from that, I have no idea how i could have over annealed this brass so badly with just a few more seconds under the flame, at the most.

How much sizing the brass will harden the brass depends on how much movement is going in the sizing process. If the die is squeezing the neck down by .014 then expanding it back out by .003", seating a bullet and firing it again that expands them out that .014. That much movement back and forth will firm then up nicely.I'm just now getting to this thread, but it is fascinating to me because it seems like it is hard to over anneal and not be able to reharden just by resizing. However, I managed to anneal about 20 pieces of brass, half Lapua and half Norma that were so soft that a bullet couldn't be held firmly in place, even after 2 or 3 resizings. I now keep them around to test for glow when setting up my annealer's timing, cause otherwise they're garbage. Aside from that, I have no idea how i could have over annealed this brass so badly with just a few more seconds under the flame, at the most.

Pareto

Silver $$ Contributor

Actually no. Most of the time, my loads are fine. But with these loads, they often came apart as I loaded them so I took them out and recovered the bullets, primers, and powder.How much sizing the brass will harden the brass depends on how much movement is going in the sizing process. If the die is squeezing the neck down by .014 then expanding it back out by .003", seating a bullet and firing it again that expands them out that .014. That much movement back and forth will firm then up nicely.Though you can't get a bullet to be held firmly, you can still load them up and fire them by hand loading them into the chamber, huh???

Not to techy but I think it's very informitive. I like all his data. I did microhardness testing for 45 years and I am very familiar with the procedure. I wish I had a copy of all the ASTM conversion charts.Thought some of you might find this of interest:

I just happened to come across this YouTube video where the guy actual had some Vickers hardness testing done for his test. Like I found in my less precise hardness testing, he found substantial increase in hardness after sizing. But like he mentioned, how much the necks are worked (reduced then expanded again) will vary the amount of increase in hardness after the annealing process. He doesn't say what he's using for his annealing process, but given the short periods of time, I'd bet it's done with an induction annealer.

RegionRat

Gold $$ Contributor

https://www.buehler.com/assets/posters/Hardness-Conversion-ASTM_10-20-1.pdfI wish I had a copy of all the ASTM conversion charts.

Will this do, or do you need the full versions?

ETA: The full ASTM have copyright protections, and they want $$ for them.

As a former Branch Chairman, I am bound by contracts to play it straight.

Most public domain stuff doesn't go very low on the HV or Knoop scales.

Last edited:

Good enough. Data is given in several hardness scales sometimes making it difficult to relate to. I'm getting old, I forget what the chart looks like to convert filar length to Knoop or Vickers hardness. Again I question why he as 2.5 KG load on the vertical axis of his chart. Is this a typo? Anyone that did microhardness testing would properly label the chart. I never used more than a 500 gram load testing to military and aircraft specs. I don't think you can load more than 500 gr on most microhardness testers. 2.5 KG is a Brinnel tester spec.https://www.buehler.com/assets/posters/Hardness-Conversion-ASTM_10-20-1.pdf

Will this do, or do you need the full versions?

ETA: The full ASTM have copyright protections, and they want $$ for them.

As a former Branch Chairman, I am bound by contracts to play it straight.

Most public domain stuff doesn't go very low on the HV or Knoop scales.

Last edited:

Similar threads

- Replies

- 21

- Views

- 3,319

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.