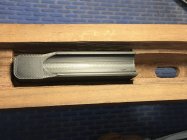

Don't normal do much tr work but this one needed rebedding . So the owner decided he wanted a full Ali block put in for this old girl . Will epoxy the block in maybe tomorrow nite hopefully and should be ready to shoot by the weekend . The old beddeding was cracked in to many places so it go a birthday

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do it yourself Stock making thread

- Thread starter joshb

- Start date

I received a stock I ordered from a guy 9 months ago, the first one was a train wreck I sent back and now I have to finish some details on the second one that didn’t get done right. I have no idea what I’m doing, but by golly I’m going to give it a try.

Attachments

LVLAaron

Gold $$ Contributor

As someone who has done far too many M40 clones based on stocks from ebay... I feel your pain.I received a stock I ordered from a guy 9 months ago, the first one was a train wreck I sent back and now I have to finish some details on the second one that didn’t get done right. I have no idea what I’m doing, but by golly I’m going to give it a try.

pdhntr

Silver $$ Contributor

I always leave that particular area of a stock about a 1/4" proud, from the grip to a couple inches forward of the trigger guard. After inletting the guard, and checking the final fit of the whole works I will remove the extra wood.I’ll be milling the pillar a wee bit to fix this little blunder.

I found I can measure all I want, but sometimes things happen, and the little bit of extra wood just in that area is nice to have on occasion, and can be removed quickly for a perfect fit.

Jim

hoz53

Gold $$ Contributor

i never put a bedding block in any of my stocks but i think i outta try it. i would glue it in and also fasten it from the outside of the slock somehow. would probably make the block to.Don't normal do much tr work but this one needed rebedding . So the owner decided he wanted a full Ali block put in for this old girl . Will epoxy the block in maybe tomorrow nite hopefully and should be ready to shoot by the weekend . The old beddeding was cracked in to many places so it go a birthday

What ya got in mind taking off or reshaping??It’s time to get the files going !

Reshaping just a tad bit.What ya got in mind taking off or reshaping??

I started with a rasp then went to 100 grit followed by 150 just to get close. I think it’s better already.

It would help if I knew what I was doing .

Attachments

Last edited:

joshb

Gold $$ Contributor

It looks like you do. Using the tape is A1 professional! It’s not rocket science!Reshaping just a tad bit.

I started with a rasp then went to 100 grit followed by 150 just to get close. I think it’s better already.

It would help if I knew what I was doing .

joshb

Gold $$ Contributor

Good advice! That’s how I do it. I’m working on one now. I left an extra 1/2 inch on the bottom. I screwed up the action inlet and had to lower it 1/4 inch to get past the gouge.I always leave that particular area of a stock about a 1/4" proud, from the grip to a couple inches forward of the trigger guard. After inletting the guard, and checking the final fit of the whole works I will remove the extra wood.

I found I can measure all I want, but sometimes things happen, and the little bit of extra wood just in that area is nice to have on occasion, and can be removed quickly for a perfect fit.

Jim

Still had a quarter inch on the bottom, thankfully!

joshb

Gold $$ Contributor

If it were I’d be in big trouble !! Thankfully I know this really good stock finisher that can hide my screw ups.It’s not rocket science!

I was able to get the weight bolt out today but not the sleeve, that was supposed to be behind a removable butt plate. The sleeve is being stubborn.

Attachments

Maybe bed the low spot under/behind the rear screw hole ?You could cut/chisel/route a notch in the curve and glue a 1/4” slab of maple on the bottom to cover it up and recut for the guard.

If you cut your pillar, you might then have to cut your trigger.

View attachment 1669421

joshb

Gold $$ Contributor

That might work, too. I hate to admit it, but I’ve scabbed pieces on to cover “issues”. One of my worst was changing a Remington clone stock into a Kodiak stock. I’ll look for a pic.Maybe bed the low spot under/behind the rear screw hole ?

Found it. Even the dog had her doubts! Extra wood behind the action and the trigger guard. Oh…and the bolt notch.

Last edited:

Use a little heat to get the sleeve out, I’m sure it’s got some epoxy on it- all else fails saw the butt off where you want it- up to the sleeve-

On the trigger guard, make sure the trigger doesn’t hit the bottom of the guard, before milling it off- or YOU will be adding a piece to build it back up-

On the trigger guard, make sure the trigger doesn’t hit the bottom of the guard, before milling it off- or YOU will be adding a piece to build it back up-

Similar threads

- Replies

- 2

- Views

- 578

- Replies

- 2

- Views

- 529

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.