You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6BR overpressure, at the bottom of tables

- Thread starter Hogu

- Start date

Hi All,

Currently reloading for 300M ISSF matches I have experienced a fairly weird overpressure occurence during a match

Rifle is a match rifle, LW 26' barrel with 1/8 twist rate

During these matches firing rate is roughly 75 rounds in an hour,

we share the rifle for 3 shooters and we clean the barrel as well as we can due to time constraints between matches.

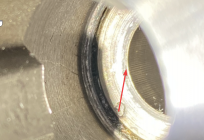

After the first 30 rounds had a small hard point at the end of the upper bolt stroke, nothing major but the brass started to show some ejector marks, but seldomly, the bolt operation remained smooth between these events. During the second match (roughly 100 rounds in the day) my fellow shooter had a stiff bolt, with evident signs of almost catastrophic overpressure, as you may see on the case shown below

View attachment 1548630View attachment 1548631

the bolt locking studs show a minimal damage not impairing the bolt action, gladly

View attachment 1548642

Our Load is:

Norma brass, once fired in another firearm

Sized using custom to our chamber dies, .267 bushing with 0,005' shoulder bump

TTL 39,40 mm using RCBS TRIMPRO 3 way cutter

Flashole deburred using K&M tool

No neck turning nor annealing

CCI BR4 Primers

VV N150 powder at 1,81 gram (27,9 gr)

Vihta load data starts at 1,85 g and ends at 2,05g for 105 gr Lapua bullets

107 gr Sierra MK seated 0,1 mm (0,005') off the lands, for COAL 60,5 m, CBTO 46,40 mm

I am at lost regarding the cause of said overpressure

-> Too light load causing secondary explosion effect ? might be weird as i am really slightly below the min load

-> Bullet jump too tight making the bullet contact the lands as the barrel heats up ?

many shooters put the bullet in the land in BR as well in ISSF rifles AFAIK

-> N150 acting due to cold weather ? (5°C during the match)

-> carbon ring ? the barrel is cleaned thoroughly after every session with Eds red and Robla Solo using a BR procedure

Well, we will shoot Manufactured ammo for the upcoming French national championship due to this unwanted halt in our reloading developpment

Many thanks to everyone of you who can help me out

Whatever caused this seems to be a mystery. But, it takes an extreme amount of pressure to bulge a case like this. Look carefully. Good luck.

Paul

FeMan

Gold $$ Contributor

Is the barrel fairly new? It sounds like it could be speed-up to me. Some barrels don't change much and some REALLY change as the bore wears in. I had a 284 barrel that did the same thing to my wife in a match. We had to take her load from 52.3 to 50.9 grains of H4350 to get back down to the same velocity and accuracy.

I had purchased 50 pieces of Norma brass for my 6BR and that brass was unbelievably soft. Even on proven loads (30.0 varget with 105 class bullet), I was getting ejector marks and loose primer pockets. I could only get 3 firings before I tossed that brass. After switching to Lapua, I have yet to lose any brass and I have loaded those pieces MANY times

Yes, overpressure.

Also, very unsupported case. Chamber needs to go all the way up to the rim.

Yup looks like the chamber is short.

@Hogu take a picture a case fully inserted in the chamber so we can see how much of the back of the case head is supported.

DHuffman

Silver $$ Contributor

I had purchased 50 pieces of Norma brass for my 6BR and that brass was unbelievably soft. Even on proven loads (30.0 varget with 105 class bullet), I was getting ejector marks and loose primer pockets. I could only get 3 firings before I tossed that brass. After switching to Lapua, I have yet to lose any brass and I have loaded those pieces MANY times

Did you work up to that load in the Norma brass or was that your Lapua load and you ran it in the Norma?

Semi-educated guess here... Tenon was potentially cut correctly, and then a generous chamfer was added... leaving that part of the case unsupported.

On the positive side, you've invented Belted 6BR

View attachment 1552597

I see more and more smiths doing this in the last few years. The giant chamfers that is. Keep playing with fire and eventually you will get burned. Apparently the term "unsupported case head" is some great mystery. Unsupported literally means just that "unsupported ". Lol. Carry on.

Paul

I started at 29.0 grains and was seeing slight shiny ejector marks even at 29.0 but moved up incrementally to 30.0.Did you work up to that load in the Norma brass or was that your Lapua load and you ran it in the Norma?

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.