It seems that many of the well-meaning posts above have ignored the fact that the OP’s load had a very high ES in both velocity and pressure. A simple over-charge would not exhibit this, so assuming that all three cartridges indeed had the same charge then simply “looking at a different reloading manual” will be of no help. With no meaningful explanation for his issue, the OP is wise to eschew further use of that particular powder.

.

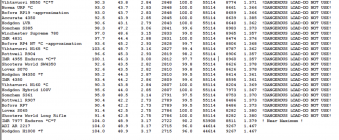

There is no meaningful ES here that I can see, that is ES values in the usual form which see (say) the highest MV for the charge weight from the 2nd shot and the lowest from the 4th or 5th which if vastly different would suggest powder incompatibility / unsuitability, ignition problems etc.

Rather as I read it, pressures / MVs rose sequentially during the session and based on the MVs by considerable amounts ending up at a dangerous level. That in itself doesn't implicate or suggest anything about powder suitability. If a powder / load is unstable it will produce random MV changes throughout even a short string.

Substantial and sequential increases in pressure as suggested here can only arise from three causes:

1. Each powder charge weight was (from whatever cause) rising unknown to the handloader who believed they were consistent.

2. Something in the firearm changed progressively between shots and increased pressures substantially shot to shot as the session progressed. eg

very severe coppering.

3. Charge compression was such that COALs were increasing alongside charges due to an excessively compressed powder column pushing them back out. Much as I love the Mauser M1893/95/96 cock on closing actions, one downside is that they need substantial effort to close the bolt and any extra resistance to final closure from an over-length cartridge jam-seating the bullet is easier to miss than on a cock on opening type. Working against that are most Swedish Mauser chamber dimensions whose throats are so long that it is usually difficult to produce a COAL that jam seats bullets.

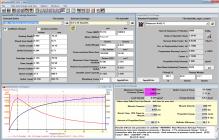

The only directly powder relevant factor that is involved is that if 1. to 3. are increasing pressures, the burn behaviours of all smokeless powders are such that since 'pressure feeds on pressure', pressures start to rise exponentially after a particular maximum safe pressure level has been passed. (As opposed to tables in handloading manuals Like Sierra's and Hornady's which use MV related columns, and internal ballistic programs such as QuickLOAD where both forms show linear pressure / MV increases throughout the entire charge weight range.)

Some powders are more affected than others by this effect, but that doesn't make them 'unsuitable' for the application in themselves, only if they are inherently unsuitable for it in the first place and with any charge weight. Nammo Vihtavuori Oy is a very careful, responsible company even by energetics company standards, and if it quotes N165 loads for 6.5X55mm and 140gn bullets, as it does, I for one take it as read that this powder is suitable for the cartridge and bullet weight.

Most experienced handloaders in this day and age of widespread chronograph use have experienced the common phenomenon of per grain or tenth grain equivalent MV increases becoming greater as charges rise, sometimes quite substantially between two modestly different charge weights. This may a result of passing a critical pressure threshold, which sees leaking or blown primers as likely results from the next charge weight increment even if very small. (This is sometimes seen though for more benign reasons due to the powder 'coming on tune' as it works more efficiently within higher pressure ranges and a higher charge burn percentage is now being achieved.) If the former (passing critical pressure levels) reason, the result is that any further charge increases produce increasingly large and excessive pressure rises quickly rising to dangerous levels.

Progressively severe barrel coppering can have a similar effect for cartridges that have been carefully and extremely consistently loaded by experienced and expert handloaders. The European F-Class Championships used to be held annually at Bisley UK in early November. As the very end of the UK's top-line fixtures season, a remarkable number of 308 Win FTR rifles had barrels which were at the 'It'll get through one last event' wear stage. Many didn't! In a fixture with six matches, four 2+15 and two 2+ 20, the symptoms were easily read. First the owners desperately scrubbing barrels out with copper removers between each stage, but in individual 15 round matches the scorer would see shots progressively score lower and on occasions the shooter started to struggle to open the bolt in the last few shots. Most people would recognise the safety implications of carrying on at this point and retired before pressures got completely out of hand. This had nothing to do with 'powder suitability' or some such factor except in that the starting point was an already high-pressure load.

The only other reasons I can conceive are the out of the box causes that cause so many handloaded ammunition problems. A different faster burning powder left in a powder measure from a previous session (but that would produce the dangerous pressures on the first charge if cartridges are shot in the order they were loaded, or if that doesn't apply should only affect one shot in the string.) Wrong grade poured back into the bottle or used and so on. But they all fail as reasons if pressures / MVs rose sequentially.