"I’m guessing you need to look at your machine. "The stylus on the interapid is 2.75” and it reads in .0005 graduations….I can easily break that down into .0001 or finer with the gap that is between the marks.

If you are preboring to the shoulder, I don’t see how the little bit of reamer deflection in the throat will cause the body to have runout…the throat is the only part cutting the lands and that’s the most flexible part of the reamer….I’m not buying it.

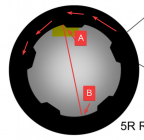

The reamer wants to go to the middle. The only way it doesn’t if we do something to cause not to.

If you are getting runout or out of round chambers, I’m guessing you need to look at your machine and/or setup.

Head stock bearings in particular.

Alan