You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Who has 277 Fury load data.

- Thread starter 46and2

- Start date

Thank you Frank for that clarification.B.S. !!!!!!!!!!!!!!!!!

That was a pretty offensive statement you made and not knowing any of the details.

The ringing of the chamber with the hybrid cases cannot be stopped running the pressures at 80k psi so far from what I understand.

The ring will show up at the junction where the steel case head meets the brass body of the case.

Run the round at 65k and it behaves like everything else. Run it at 80k and things are going to change. No way around it.

Even Sig has told us our BB material stands up better to the abuse of 80k psi vs standard 416R and we have made them a ton of barrels for R&D as well as we make them a lot of ammunition test barrels. Both accuracy and pressure and velocity.

On production guns they are adding coatings and metal treatments to help with the ringing of the chambers to prolong service life.

I just love it when people say things and they have no clue as to what is going on!

Later, Frank

Bartlein Barrels

BTW, I think you simply misunderstood what I said.

What issue(s) does that ringing present when if forms?

Difficulty chambering cartridges? More pressure? Damage to cases, shortening case life?

Last edited:

Thanks for responding. Not sure if I misunderstood it or not but it came across as it was bad material from us. That's how it looked.Thank you Frank for that clarification.

BTW, I think you simply misunderstood what I said.

What issue(s) does that ringing present when if forms?

Difficulty chambering cartridges? More pressure? Damage to cases, shortening case life?

What issues does it bring up the ring/groove that is made in the chamber.

I do know that even before the ring starts at 80k psi bolt lift is very hard. To the point that you have to beat it open.

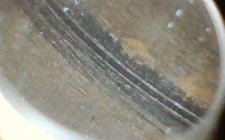

Around 500ish rounds the ring in the chamber from what I've seen is approx. .001" deep. Around 700ish rounds the ring/groove is around .002" deep. I've seen it and heard it from a three different places now. With measurements and pictures to back it up. This is in standard good quality 416R material. I do believe CM material reacts the same way. Extraction gets even more difficult as the ring/groove becomes more pronounced. I've been told by the same makers/ammo maker/testers that the 400modBB material stands up better but does not make it go away. That's why they are coating/metal treating the steel and chambers on the production guns to extend the barrel wear/life of the chamber to help prevent it from being a real problem.

The heat generated at 80k psi is much greater also. Also at 80k psi when you run the barrel a shorter length you can expect it to possibly cause accuracy issues. Same thing is seen with 338 Lapua. Even though the 338 Lapua isn't at 80k psi when you run the barrel length shorter (down to 20" finish vs a 24" or 26" or 27" etc...) there is so much pressure behind the heel of the bullet when it leaves the muzzle it causes the bullet to be tipping up more at the heel and it takes longer for the bullet to possibly recover which can effect the accuracy.

Thanks for the info and the dialogue. It's much appreciated.Thanks for responding. Not sure if I misunderstood it or not but it came across as it was bad material from us. That's how it looked.

What issues does it bring up the ring/groove that is made in the chamber.

I do know that even before the ring starts at 80k psi bolt lift is very hard. To the point that you have to beat it open.

Around 500ish rounds the ring in the chamber from what I've seen is approx. .001" deep. Around 700ish rounds the ring/groove is around .002" deep. I've seen it and heard it from a three different places now. With measurements and pictures to back it up. This is in standard good quality 416R material. I do believe CM material reacts the same way. Extraction gets even more difficult as the ring/groove becomes more pronounced. I've been told by the same makers/ammo maker/testers that the 400modBB material stands up better but does not make it go away. That's why they are coating/metal treating the steel and chambers on the production guns to extend the barrel wear/life of the chamber to help prevent it from being a real problem.

The heat generated at 80k psi is much greater also. Also at 80k psi when you run the barrel a shorter length you can expect it to possibly cause accuracy issues. Same thing is seen with 338 Lapua. Even though the 338 Lapua isn't at 80k psi when you run the barrel length shorter (down to 20" finish vs a 24" or 26" or 27" etc...) there is so much pressure behind the heel of the bullet when it leaves the muzzle it causes the bullet to be tipping up more at the heel and it takes longer for the bullet to possibly recover which can effect the accuracy.

Hmmm??? So, the "ring" is a groove.

Fascinating to me in trying to understand the physics of that and why that would occur; like what is it that's forming that groove? I can see how extraction can be a problem with a .001"+ deep ring groove where the case material flows into it and isn't able to spring back enough to get the clearance it needs for extraction.

No doubt I'm running my loads in these cases over that 65K out of 26" heavy barrel. But I'm pretty sure they're well short of 80K.

I think you're right on about that extra pressure on the heel of a bullet causing a little more tipping that'll cause a longer time for it to stabilize. I hadn't given that aspect any thought before.

Walt Krafft

Gold $$ Contributor

The ring is formed from the steel head not springing back like brass does. I played with it a little and decided for a competition gun the barrel life was just going to be too short to fool with it. The Remington actions used for testing have held up well except for the beating they take opening and extracting the rounds.

^^^^ what Walt said above! Walt can correct me if I'm wrong to what I type below.The ring is formed from the steel head not springing back like brass does. I played with it a little and decided for a competition gun the barrel life was just going to be too short to fool with it. The Remington actions used for testing have held up well except for the beating they take opening and extracting the rounds.

You have two dissimilar metals... brass case body and the steel case head. They will expand/react differently under pressure. I think that is the issue.

Yes I call it a ring. Call it a ridge, shoulder, lip etc...

Welcome!Thanks for the info and the dialogue. It's much appreciated.

I think you're right on about that extra pressure on the heel of a bullet causing a little more tipping that'll cause a longer time for it to stabilize. I hadn't given that aspect any thought before.

The pressure on the heel of the bullet leaving the muzzle in the shorter barrels has been proven. Again not just in this caliber but like 338 Lapua like I stated earlier. Again in the 338 Lapua shooting a 20" barrel length it's going to be harder to get that gun to shoot say sub .75moa. Most likely more in the range of .75 to 1moa but shoot a longer barrel like 24" or 27" and the same loads will shoot better or should I say more consistently smaller groups. Just the nature of the beast.

How short and where does it start to show it's ugly face or start to show possible issues. That I cannot answer exactly. Might be a case of... what is your accuracy requirement?

I know from going to a 16" barrel and getting a .8moa with no problem... but as they chopped off 1" off each time the accuracy deteriorated steadily. At 13" if I recall correctly.... it was tough to get it under 1.3moa or so.

Now how much better does a 20" or 24" shoot? That I can't tell you.

Leave your barrel a longer length from an accuracy point of view is going to do nothing but help.

Last edited:

The ring is formed from the steel head not springing back like brass does. I played with it a little and decided for a competition gun the barrel life was just going to be too short to fool with it. The Remington actions used for testing have held up well except for the beating they take opening and extracting the rounds.

I do fully understand the different metal properties (as someone who's worked with various aircraft sheetmetals), where brass and steel react to pressure differently.^^^^ what Walt said above! Walt can correct me if I'm wrong to what I type below.

You have two dissimilar metals... brass case body and the steel case head. They will expand/react differently under pressure. I think that is the issue.

Yes I call it a ring. Call it a ridge, shoulder, lip etc...

I was a bit surprised when I resized one of these cases after firing it that the steel web area had so easily been sized down to the same dimension before being fired (no noticeable difference from a standard brass case). I was expecting it so spring back more where I could measure it. Maybe it did and it's just that my caliper just doesn't have the resolution to see it???

I'm very curious about the physics as to how that junction produces a grooved ring on the steel surface of a steel barrel. (I just have in insatiable curiosity about how things work, all things . . . which propelled me into precision reloading

. . . and if it's a powder that doesn't completely burn in those short barrels, that can exacerbate that too. . . huh?Welcome!

The pressure on the heel of the bullet leaving the muzzle in the shorter barrels has been proven. Again not just in this caliber but like 338 Lapua like I stated earlier. Again in the 338 Lapua shooting a 20" barrel length it's going to be harder to get that gun to shoot say sub .75moa. Most likely more in the range of .75 to 1moa but shoot a longer barrel like 24" or 27" and the same loads will shoot better or should I say more consistently smaller groups. Just the nature of the beast.

How short and where does it start to show it's ugly face or start to show possible issues. That I cannot answer exactly. Might be a case of... what is your accuracy requirement?

I know from going to a 16" barrel and getting a .8moa with no problem... but as they chopped off 1" off each time the accuracy deteriorated steadily. At 13" if I recall correctly.... it was tough to get it under 1.3moa or so.

Now how much better does a 20" or 24" shoot? That I can't tell you.

Leave your barrel a longer length from an accuracy point of view is going to do nothing but help.

Last edited:

Walt Krafft

Gold $$ Contributor

Picture a ball peen hammer hitting a piece of steel. It leaves a dent. The steel head of the case is doing the same thing to the barrel at the higher pressures this cartridge is designed for. A little bit at a time until there is a groove that restricts extraction.I do fully understand the different metal properties (as someone who's worked with various aircraft sheetmetals), where brass and steel react to pressure differently.

I was a bit surprised when I resized one of these cases after firing it that the steel web area had so easily been sized down to the same dimension before being fired (no noticeable difference from a standard brass case). I was expecting it so spring back more where I could measure it. Maybe it did and it's just that my caliper just doesn't have the resolution to see it???

I'm very curious about the physics as to how that junction produces a grooved ring on the steel surface of a steel barrel. (I just have in insatiable curiosity about how things work, all things . . . which propelled me into precision reloading).

View attachment 1685900

. . . and if it's a powder that doesn't completely burn in those short barrels, that can exacerbate that too. . . huh?

A caliper is not the correct tool for measuring case head expansion.

If the powder is not completely burned, you probably will not get the high pressure.

So I found a couple of these cases in the dirt at the range and started looking into it. Looks like it's basically a 7-08 that runs a few fps faster. What's the point, is there really an advantage worth the extra cost/ complexity/risk? I mean I understand what Sig's motivation is but why not just rebarrel an AR10 to 7-08? Not trying to start an argument just curious.

Why not is because the military was/is after something new that meets their specifications. The military was after a new generation weapon system. It's like when the military went from the M1 Garand to the M14.So I found a couple of these cases in the dirt at the range and started looking into it. Looks like it's basically a 7-08 that runs a few fps faster. What's the point, is there really an advantage worth the extra cost/ complexity/risk? I mean I understand what Sig's motivation is but why not just rebarrel an AR10 to 7-08? Not trying to start an argument just curious.

jackieschmidt

Gold $$ Contributor

One thing to remember, a rifle in combat is not using reloaded cases that have experienced multiple firings.

Walt Krafft

Gold $$ Contributor

Cut the barrel off to 16 inches and you cant get the performance specified from a brass case.

So You really Have No Clue.So I found a couple of these cases in the dirt at the range and started looking into it. Looks like it's basically a 7-08 that runs a few fps faster. What's the point, is there really an advantage worth the extra cost/ complexity/risk? I mean I understand what Sig's motivation is but why not just rebarrel an AR10 to 7-08? Not trying to start an argument just curious.

And Your response verify that.

Not trying to start an argument.

It wasn't Sig's doing.So I found a couple of these cases in the dirt at the range and started looking into it. Looks like it's basically a 7-08 that runs a few fps faster. What's the point, is there really an advantage worth the extra cost/ complexity/risk? I mean I understand what Sig's motivation is but why not just rebarrel an AR10 to 7-08? Not trying to start an argument just curious.

It was some high ranking guy from what I've been told/started at the top idea. Don't quote me on that. I might not even be in the ballpark.

A spec was written.... 140ish grain bullet at 3000+fps and 6.8mm and on a standard short action length round. That was it as far as I know. Then it was turned over to private industry to come up with something. I believe due to the way things are changing on the battlefield with ballistic armor on people and vehicles. The need is seen for more penetration at say 300 yards or further and the 5.56 isn't cutting it.

When this came about... I said... Special Forces etc... are already using 6.5CM and 260 Rem. and as well AP match type bullets have been being made and tested in 6.5mm. I'm pretty sure a 6.5mm with a 130ish grain bullet at 2800fps or so will do what you need. Just my opinion.

A standard loaded 7mm-08 won't make the velocity spec given. So basically a new round needed to be developed.So I found a couple of these cases in the dirt at the range and started looking into it. Looks like it's basically a 7-08 that runs a few fps faster. What's the point, is there really an advantage worth the extra cost/ complexity/risk? I mean I understand what Sig's motivation is but why not just rebarrel an AR10 to 7-08? Not trying to start an argument just curious.

Though I summarized this in another thread, point out in this thread that it's not that "hammering" that's resulting in a ring. The ring is the result of the hot gases blowing out from the seam where the bass case body meets the steel base causing the same kind of etching on the chamber wall as we see when gasses blow by primers and etch bolt faces. Eventually, that etching gets deep enough where the brass will mold into that groove and not have enough springback to get out resulting in a cartridge stuck in the chamber.Picture a ball peen hammer hitting a piece of steel. It leaves a dent. The steel head of the case is doing the same thing to the barrel at the higher pressures this cartridge is designed for. A little bit at a time until there is a groove that restricts extraction.

A caliper is not the correct tool for measuring case head expansion.

If the powder is not completely burned, you probably will not get the high pressure.

Walt Krafft

Gold $$ Contributor

You are wrong. There is no gas leakage. There would be smoke on the cases and I have never seen that in thousands of rounds.Though I summarized this in another thread, point out in this thread that it's not that "hammering" that's resulting in a ring. The ring is the result of the hot gases blowing out from the seam where the bass case body meets the steel base causing the same kind of etching on the chamber wall as we see when gasses blow by primers and etch bolt faces. Eventually, that etching gets deep enough where the brass will mold into that groove and not have enough springback to get out resulting in a cartridge stuck in the chamber.

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.