A P&V barrel (pressure and velocity) has a threaded pressure port in it. The port into the chamber is .250” in diameter and the port is .175” behind the shoulder. So the brass will push against the sensor to give the pressure reading. I think this is the reason whey it can effect the accuracy a little.What are the differences between a P&V barrel and an accuracy one that have the most influence on accuracy?

Thank You

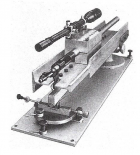

A straight up velocity test barrel or a test barrel in an accuracy rig eliminates this. Some accuracy test barrels are just 1.250” straight usually and sit in a rail gun type fixture.