xr650rRider

Silver $$ Contributor

Am I the only one wondering why the barrel was unscrewed?

Don't have the answer but 90% that want to run a suppressor want a short barrel. How short can you handle with action in place?

Am I the only one wondering why the barrel was unscrewed?

Hello, my name is Judd and I got that tshirt.I've also seen where someone installed too long of a screw to hold the rail or front scope ring on. The screw chews up the threads on the barrel tennon and if not noticed and repaired before unscrewing the barrel galling is bound to happen with a steel or stainless action.

I have very nearly gotten caught by this on an A bolt. The action broke loose just fine then started to stick. I stopped, put the barreled action muzzle down in the bench vise, and plugged the chamber with a piece of rag. I put about an ounce of 75-90 gear oil in the receiver ring. I heated it with a heat gun until it was too hot to hold, then went for a coffee. When I got back, I dumped out the excess oil (messy!) Then put the thing back in the barrel vise. I was using an out side wrench (which, I felt, may have added to the problem, initially) and I took care not to tighten that wrench onto the receiver too much. I just started wiggling the receiver back and forth with the wrench, until it finally spun right off.So what’s the procedure for removing the barrel on an A bolt that may or may not be galled? My experience with galled parts is that applying heat makes it worse ? Cut the tenon off, bore it out and pick out the threads then chase the receiver threads?

FYI this is why I always put a dab of anti seize on all my barrels

I think a lot of issues people have with problem solving on things like this is that they are in a hurry, and dont stop and take the time to think about devising a plan “B” before they paint themselves in a corner that can get out of.I took a Browning A Bolt to a semi local PRS rifle building firm near me and talked with them. He told me about the problems associated with Brownings and said he wouldnt do it. I asked him if he would recommend someone and he sent me to a gentleman. An older gentleman who has years of experience. I talked to him in the phone and we set up an appointment for me to bring my rifle by. We were talking when I dropped my rifle off, I told him of my visit to the PRS builders , he sort of laughed. When he finished my rifle I went to pick it up, and again we got to talking, he says " I dont know why those boys didnt want to mess with the Brownings". The way he talked Brownings are no more trouble than anything else and they take a re barrel very well with very good results. If I had work to be done today, I would make the drive to Utica MS. The one he did for me shoots very well.

Ya', my plan B is, I'm already in my late 60s, a gunsmith school grad with over 30yrs of 'bench' experience. I already work with many other 'problems' most don't want. I have more than I can do in a timely manner now, why bother with what could be a real problem that won't pay any extra, and possibly delay other decent paying work, just to please someone with hardon for A Bolts/X Bolts that most likely will not be a repeat client/customer?I think a lot of issues people have with problem solving on things like this is that they are in a hurry, and dont stop and take the time to think about devising a plan “B” before they paint themselves in a corner that can get out of.

My comment wasn’t directed at Brownings exclusively, but could apply. There are many things a person does that may have hurdle to cross in the process. Being able to come up with a solution is the point.Ya', my plan B is, I'm already in my late 60s, a gunsmith school grad with over 30yrs of 'bench' experience. I already work with many other 'problems' most don't want. I have more than I can do in a timely manner now, why bother with what could be a real problem that won't pay any extra, and possibly delay other decent paying work, just to please someone with hardon for A Bolts/X Bolts that most likely will not be a repeat client/customer?

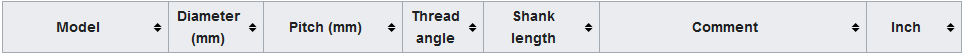

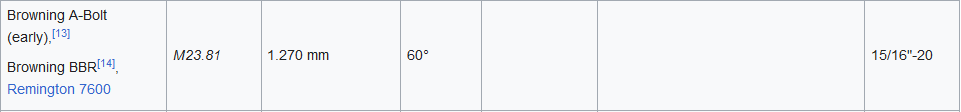

Jackie, Stan Ware had a little niche' market rebarreling the A-Bolts. Some had the threads beat up from the factory but most weren't. A bigger issue was tweaking the actions when removing the barrels conventionally. The factory barrel would be cut off about 1" ahead of the receiver, the reciever would go into a 5 gallon bucket of diesel fuel for a day or so and then he'd bore the old stub out. Most of the time, the threaded stub would just screw out by hand as the wall thickness was reduced during the boring process.With all of this talk of interference thread fits in Stainless Steel Actions, my first thought is how the heck does Browning get the things together.

We have all had that “uh o” moment when we are fitting a new barrel and it suddenly, about 2/3 the way on, has a “catch“. You are thinking, “Oh Sh-t.“, hoping it will come off.

Al, do you think one with really messed up threads could be brought back to life the way I did that Bat.?Jackie, Stan Ware had a little niche' market rebarreling the A-Bolts. Some had the threads beat up from the factory but most weren't. A bigger issue was tweaking the actions when removing the barrels conventionally. The factory barrel would be cut off about 1" ahead of the receiver, the reciever would go into a 5 gallon bucket of diesel fuel for a day or so and then he'd bore the old stub out. Most of the time, the the threaded stub would just screw out by hand as the wall thickness was reduced during the boring process.

Geez....I must have cut off a dozen Browning barrels for him on his horizontal band saw. "Do something to make my life easier instead of harder, Nyhus. Cut these (blank-blank) A-Bolt barrels off for me. If you scratch the action, I'll charge your azz after I fix your screw up."

Jackie Im nowhere near the machinist you are but i dont see why not. We pretty much do the same thing with remington 700s when we true them with oversized threads. I like the idea of soaking the cut off barrel in diesel and boring it out in reverse. I used that trick on a hydraulic cylinder cap that was seized and the barrel was damaged. only the first few threads were damaged and a simple chase with a thread tool cleaned them upAl, do you think one with really messed up threads could be brought back to life the way I did that Bat.?

Very possibly.Al, do you think one with really messed up threads could be brought back to life the way I did that Bat.?