I generally weigh the fully-prepped but empty cases prior to loading, then determine water volume after firing. Determining water volume after case prep, but prior to firing will only give the water volume of a re-sized case. What you're after is to determine the water volume of a fired case, meaning a case that has fully expanded to fit the chamber, which can also referred to as the pressure cell volume because it is the the effective volume in which the powder combustion takes place.

In order to determine water volume, it is unnecessary to use additives such as alcohol or detergent. In fact, such additives increase the likelihood of forming bubbles inside the case that will increase variance within the measurements. I deprime the cases first, then re-insert the primer backwards to minimize any getting water into any additional space past the flash hole, which can introduce additional weight/volume variance. Tare the balance to the empty case. Fill the case almost to the top of the neck with an eyedropper, or simply by dunking the case in a bowl of tap water and drying off the outside carefully with a paper towel. Place a fingertip over the case mouth and shake it downward several times to move any bubbles inside to the top. Using the eyedropper or a drop of water on the fingertip, fill the case to the top using a lamp of some sort to backlight the meniscus. The back lighting makes it very easy to visually determine when the case is full with the meniscus completely flat. Re-weigh the case to determine the water weight. Use a value for the density of water of 1.000 g per cubic centimeter/milliliter, or 15.4324 gr per cubic centimeter/milliliter. Frankly, the units don't really matter. You can find whatever conversion factor you need online, so whatever units your balance is set to will work just fine. I posted a more detailed version of the method I use here at A.S. some time a ago:

Readers here will see many, many posts regarding determination of case volume. There seem to be about as many different methods as there are posts on the topic, such as using detergent or alcohol mixed with the water, how the primer pockets are sealed, how "full" the case should be filled...

forum.accurateshooter.com

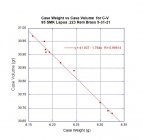

Once you have determined the water volume of some cases, you can then investigate several interesting questions. For example, does the internal volume you measured correlate with velocity? In other words, as case weight increases, does velocity also increase for a given charge weight? It should. However, sources of limiting error become critical in such analyses. If you plot case weight versus case volume, you should observe a very nice linear correlation. I do this regularly with all my brass preps and routinely observe this to be true. Case weight of fired cases

does have a strong linear relationship to case volume. Nonetheless, various sources of error in case volume determination and volume of the extractor grooves/primer pockets means that not all of the data points within your case weight versus case volume scatter plots will fall directly on the best fit curve of the data. There will always be some outliers. In general, the better your technique in determining water volume, the more closely the data points will be to the linear curve fit. But it is important to re-iterate that there will always be some outliers. Below is a graph for 10 cases I did just a few days ago. You can see from the "R" value (0.99) of the linear curve that the data show a strong linear correlation between case weight and case volume. But there are clearly some outliers that do not fall directly on the best fit linear curve. Those anomalies need to be taken into account when using such data to interpret real-world results, such as velocity. It is always interesting to try to determine whether outliers from the mean velocity might be caused by case volume variance. For example, might that one velocity reading that was noticeably higher than the others in the string happen because of a case that had markedly lower volume (higher weight) than the others? It is certainly worth the attempt to establish such correlations, but just be aware because of the outliers that it may not always be possible to make such conclusions in every instance due to the outliers/sources of error. However, it is still a good learning experience, IMO.

Because of the limitations (sources of error) inherent in determination of case water volume, I generally do not try to squeeze too much out of the resulting data. Picking it over with a fine tooth comb may not be the best investment of your time. Because I am 100% convinced in the general correlation of case weight to case volume, I will typically sort a Lot# (batch) of cases into three or four distinct weight groups. Even with the presence of a few outliers, there is a very high likelihood that the case volume variance among the individual weight sort groups will be smaller than the case volume variance of unsorted brass. In other words, the case volume variance of weight-sorted cases is almost always tighter than if I do nothing at all. That is really all I am interested in accomplishing...just tightening up case volume a bit within the sorted brass weight groups. I do not claim there can't still be a few outliers, or that all of the sorted cases will somehow exhibit perfect weight to volume correlation. That isn't so. But they will usually be better than if I did nothing. That is what I really mean by not trying to interpret the case volume/weight data to too fine a level. All you're really trying to do is improve the consistency of case volume within the sorted groups, not to make it perfect, or make conclusions about individual cases that may or may not be true depending on how close to the best straight line curve fit they fall. For such an exercise, weighing cases is a good way to go. It is fast and very simple to do, and the sorted case volumes will jot only

never be worse than the unsorted batch of brass as a whole, they will usually be

more consistent. So you get a small but measurable benefit for relatively little work.