The advantage of alcohol is that it has very little surface tension and it lays very flat on top. Probably less chance of getting air bubbles trapped in the case. I would fill the cases maybe 3/4 full and tap them to see if air bubbles are released. Quit weighing since both my varmint rifles easily shoot under 0.400" with just about any load.I tested Norma 6XC brass today. Since this is my first attempt I could use some feedback. This was my process:

trimmed brass

chamfered necks

neck sized

wet tumbled

primed with cleaned & tumbled primers with anvils removed ( I was advised by an engineer to insert

( primers upside down to have a more uniform volume)

weighed each brass

filled with drops of water

weighed brass again

calculated weight of water ( I’ve read that alcohol is a better medium, not sure )

After all the effort, what do I do with the results other than sort the brass?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First try @ volume testing

- Thread starter Topwater

- Start date

RegionRat

Gold $$ Contributor

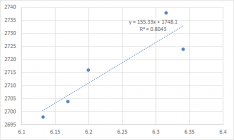

Ned's data from post #19When you load those sorted cases up, I'd suggest starting with comparing velocities for a few cases from the very largest and smallest volumes within the total range. That will give you the best chance of detecting a difference in velocity caused by case volume variance, if there is going to be one. Just a few days ago, I fired a charge weight test using the same .223 Rem brass prep I used to illustrate the linear relationship between case weight and case volume in Post #17 above. I typically do not sort cases by weight during load development, only for matches after a final load has been obtained. I figure the variance during testing is acceptable. if I can get the velocity and precision working acceptably without sorting them, those parameters will only improve when I sort the brass for a match, or at worst, stay the same. For that reason, the cases used in this charge weight test were not weight-sorted, although I did determine the weight of each de-primed case afterward.

In any event, what I again observed from this charge weight testing experiment is that at any given charge weight, velocity outliers (high/low) were typically associated with the very heaviest or very lightest cases. Variance in velocity was harder to clearly associate with cases having weights somewhere closer to the middle of the overall weight range. This is more anecdotal information supporting my belief that extreme variance in case weight/volume can readily be detected in terms of the magnitude in its effect on velocity. The effect of minor case weight/volume variance on velocity become "lost in the noise", so to speak. In other words, minor case weight/volume variance is not the limiting (largest) source of error in velocity and can be masked by the other factor(s) that are limiting sources of error. Here is a small example from a single charge weight of that testing to illustrate the point:

Case weight (g) Velocity (fps)

6.1691 2704

6.3409 2724

6.3150 2738

6.1993 2716

6.1315 2698

Note that the two cases in the 6.3+g range yielded the highest velocities, whereas the lightest case (6.1315 g) yielded the lowest velocity. In contrast, the velocity of the 6.3150 g case was slightly higher than the 6.3409 g case. The caveat to these types of exercises is obviously the very small sample number. Nonetheless, I have previously determined velocity using slightly larger numbers (10 each) of cases from the heaviest (>6.3 g) and lightest (<6.15g) cases within the Lot#, and the velocity variance trend was always the same. On average, the heaviest cases gave velocities that were ~25-35 fps faster than the lightest cases. I have also observed this trend often enough with smaller sample groups that I believe it to be a relatively safe assumption. Obviously, the relative volume of the cartridge used will be a factor. It is not too difficult to see the effect of case volume variance with the relatively small .223 Rem cartridge. In my hands, as the cartridge capacity increases, the effects seem to become less obvious.

With this particular .223 Rem load, I can usually obtain ES values (5-shot groups) of around 15-20 fps. What I believe this indicates is that the case weight/volume variance has to be large enough to cause readily detectable and statistically significant velocity changes over other inherent factor(s) that also generate velocity variance such as primers, charge weight variance, neck tension, bullet weight, etc. In other words, starting with the most extreme variance in case weight/volume (i.e. the smallest and largest volume cases within the sort) will give you the best chance of detecting an effect on velocity, if it actually can be detected. If you do such a test and obtain a statistically significant difference, that also implies that sorting cases by weight or volume might be beneficial even within a narrower case weight/volume range where it is much more difficult to detect above the background noise (i.e. other factors that cause velocity variance). In such a case, it can be argued that if the velocity variance due to case volume variance is small enough to be masked by other factors also causing velocity variance, it can be ignored. However, sources of error are often additive. So it can also be argued that sorting cases by a weight/volume increment that is small enough it is difficult to detect is effectively the same as removing that source of error. I favor the second interpretation. Removing a slightly smaller source of velocity error when other larger sources of error are also present is unlikely to provide instant gratification or readily observable differences in terms of velocity ES/SD values, but it will never make your results worse.

This is exactly what I was trying to point out in my earlier post. Sorting cases by weight/volume into three or four distinct sort groups can really do two things for you. The first and foremost is to remove the extreme velocity outliers caused by case weight/volume variance. The second and less obvious or noticeable result is to minimize a smaller source of error that, even if hard to detect over other sources of error, is nonetheless present. The first of these benefits is usually easy to detect, the second requires a little faith. As you noted in your post above, determining case water volume in a precise and accurate manner can be extremely labor-intensive and tedious if you are working with large numbers of cases. In contrast, weighing cases as a surrogate for volume determination is relatively simple and does not require huge amounts of time. Thus the practical benefit of one approach over the other can often be weighed in terms of the intended use. Does your shooting typically require large numbers of cases? Or can you get by with a much smaller total number cases? In the first example, sorting cases by weight is probably the better approach. This is what I do for F-Class matches, and I don't concern myself with keeping the weight-sorted cases separate after firing them. This makes brass prep easier as I do it in large batches. However, it also means I have to weight sort the cases after each prep. I don't find that to be too much trouble. In the second example, it shouldn't be too painful to sort a few cases by volume, which is the more accurate/precise method, and then keep the weight groups separate during subsequent brass preps so you don't have to go through the volume sorting process more than once.

When we measure outboard cylinder head volumes we use RV antifreeze. Alcohol can evaporate really quickly. I will add that I don't measure brass volume because I need help in way too many other areas.

I like others think case volume measurement is as important as the other tuning processes in reloading. There are many variables inside the case and after the barrel to see a defined change on target from equal vol.

What we can refine with case selection and what goes inside is all about achieving a consistent pressure pulse to push the bullet.

Even pressures shot to shot is one ultimate gain for a reloader.

Controlling and tuning shot pressure regardless of load component variables will see a result on target and is mechanically possible but would take some fun out of shooting.

LC

What we can refine with case selection and what goes inside is all about achieving a consistent pressure pulse to push the bullet.

Even pressures shot to shot is one ultimate gain for a reloader.

Controlling and tuning shot pressure regardless of load component variables will see a result on target and is mechanically possible but would take some fun out of shooting.

LC

Last edited:

Isopropyl alcohol evaporates slow enough it shouldn't be a problem for cases. I can see RV antifreeze being good for larger engine heads. Methanol evaporates faster.When we measure outboard cylinder head volumes we use RV antifreeze. Alcohol can evaporate really quickly. I will add that I don't measure brass volume because I need help in way too many other areas.

I look at it this way. We all know that ES often does not directly correspond to group size, but I think ES can be a sign of the consistency of our loading process. If our cases have similar enough capacity, and they are sized similarly enough, and our powder charges are consistent enough, we ought to have a low ES.

When I do my short range initial testing for 1000 yd BR I use a LabRadar. When I am close to the loads the barrel likes the ES is usually single digits. When I started seating my primers with the K&M Gauge--where I can measure an exact crush for each primer and pocket, my ES for my good loads dropped from low teens to single digits.

So for me, if I am already getting single digit ES, then my loading methods are valid. All I do is weight sort cases, mainly looking for outliers. I understand that weight sorting is only a rough correlation to volume, but if I am already getting single digit ES in a 6 BRA, then I think that method is valid and my focus should be on fine tuning the load at 1000 yds the day before the match.

When I do my short range initial testing for 1000 yd BR I use a LabRadar. When I am close to the loads the barrel likes the ES is usually single digits. When I started seating my primers with the K&M Gauge--where I can measure an exact crush for each primer and pocket, my ES for my good loads dropped from low teens to single digits.

So for me, if I am already getting single digit ES, then my loading methods are valid. All I do is weight sort cases, mainly looking for outliers. I understand that weight sorting is only a rough correlation to volume, but if I am already getting single digit ES in a 6 BRA, then I think that method is valid and my focus should be on fine tuning the load at 1000 yds the day before the match.

I weigh sort my brass and bullets matching the heaviest weight cases with the heaviest bullets and start shooting my string in order from the heaviest to lightest case and bullets.

Shooting the higher velocity cases with the heavier bullets and the lower velocity cases and lighter weight bullets might help maintain improved vertical displacement when shooting groups verses unbatched case/bullet sorting For Longrange.

Shooting the higher velocity cases with the heavier bullets and the lower velocity cases and lighter weight bullets might help maintain improved vertical displacement when shooting groups verses unbatched case/bullet sorting For Longrange.

I'm in process of testing this as well.

This type of testing is hard to really do, because there are so many variables in it. You need cases to be the EXACT same size to get valid data that doesn't add more questions than answered. (Neck length, neck ID, etc.) Throw in the frustration of the shortage and cost of reloading components, and this has become a long term project. Maybe if I win the lottery, I can finish this lifetime?

I originally just measured resized volume, and still got variances in velocity. Single digit, but variances nonetheless. But I did notice that the fired shoulder of brass varies by 0.0005. I assume this is due to brass thickness and tested this out after testing this out with 7 rounds. (I was using a labradar with the piet trigger, and it missed some shots. I'll be moving forward with doing this with both labradar and magnetospeed.)

My test was with the same load, primers from the same lot, the same powder from the same jug, with just different volumes/shoulder bump at +/- 0.0005

1 - 50.52

2 - 50.70

3 - 50.28

4 - 50.88

5 - 50.72

6 - 50.74

7 - 51.10

Velocity

2840

2821

2835

2860

2846

2832

2949

I am currently sorting brass by fired shoulder, and measuring the fired volume (fv), and sorted brass by resized shoulder. I'll be making notes on each piece of brass, labeling them with a number to easily identify and find them.

At this point, I am looking at extreme controls after the data I found, I have sorted primer/bullets to match by weight/OAL/ogive length, which in turn makes me pretty mad no one makes a seating die based on ogive yet. (Specifically for hybrid target bullets.) This will be done with 5 rounds first to see if there is any correlation, and 10 rounds on top of that with random primers/bullets of various measurements.

I'd love to test this out at the range, with a single case/set up, as mentioned by gme. I don't have the resources to do so, but I'd love to share this so more eyes/hands can follow through.

This type of testing is hard to really do, because there are so many variables in it. You need cases to be the EXACT same size to get valid data that doesn't add more questions than answered. (Neck length, neck ID, etc.) Throw in the frustration of the shortage and cost of reloading components, and this has become a long term project. Maybe if I win the lottery, I can finish this lifetime?

I originally just measured resized volume, and still got variances in velocity. Single digit, but variances nonetheless. But I did notice that the fired shoulder of brass varies by 0.0005. I assume this is due to brass thickness and tested this out after testing this out with 7 rounds. (I was using a labradar with the piet trigger, and it missed some shots. I'll be moving forward with doing this with both labradar and magnetospeed.)

My test was with the same load, primers from the same lot, the same powder from the same jug, with just different volumes/shoulder bump at +/- 0.0005

1 - 50.52

2 - 50.70

3 - 50.28

4 - 50.88

5 - 50.72

6 - 50.74

7 - 51.10

Velocity

2840

2821

2835

2860

2846

2832

2949

I am currently sorting brass by fired shoulder, and measuring the fired volume (fv), and sorted brass by resized shoulder. I'll be making notes on each piece of brass, labeling them with a number to easily identify and find them.

At this point, I am looking at extreme controls after the data I found, I have sorted primer/bullets to match by weight/OAL/ogive length, which in turn makes me pretty mad no one makes a seating die based on ogive yet. (Specifically for hybrid target bullets.) This will be done with 5 rounds first to see if there is any correlation, and 10 rounds on top of that with random primers/bullets of various measurements.

I'd love to test this out at the range, with a single case/set up, as mentioned by gme. I don't have the resources to do so, but I'd love to share this so more eyes/hands can follow through.

RegionRat

Gold $$ Contributor

Just a few random thoughts while I am stuck waiting... skip to the last paragraph for the punch line...Honestly speaking, this is out of plain curiousity. For my current barrel, I have two loads that shoot 1/3 MOA at 100-300 yards, that I've tested multiple days. I'm fine where I am at, I'm just curious as to what makes these things accurate and precise

Many of us on the forum have been reloading at home for decades. Many times folks start out and get lucky, other times they struggle up front. Far too many give up too soon.

I was the first type, or at least I think I was... My very first attempts at rifle hand loads though a factory Rem 700 30-06 were so much better than factory ammo that I was fat dumb and happy for a while.

That was northwest Indiana in the 60's and 70's where there was no highpower hunting season for the most part. We only had shotgun and archery for deer, so highpower was only for occasional woodchucks or predator controls.

I thought in terms of farm work that my 3/4 MOA was pretty good considering most shots were under 300 yards. We didn't have rangefinders. We counted fence posts or corn rows..... What did I know? I shot with peep sights and holdover after doing load testing with a K-Mart scope. I wasn't exposed to HP competition or benchrest at that time and place. I was vaguely aware of what accuracy could be through reading magazines at the barbershop since I couldn't afford them and nobody around had the interest.

Fast forward to being recruited at 19 years old into an advanced defense company and I found out that what I thought was great was just so-so in other circles. It was then I learned that those early results would be temporary and sometimes hard to repeat without serious effort. (I'm mostly describing brass prep at this point.)

I learned what state of the art really meant and that my early success at 3/4 MOA was good, but the next batch of brass wasn't the same result.

It took me into the early 80's to sort out for myself what was important and what wasn't, but I also had world class experts as mentors so I probably got there much faster by their advice. Keep in mind by now I was building and running labs and doing advanced weapons systems development for a living. However, Uncle Sam may load by the millions, but he he has zero interest in reloading....

Things at work taught me a lot, but at home I was subject to my own pocketbook. At that time we had Bower's Wholesale in downtown LA and the Sierra Bullet factory was local and also very kind to young competitors.

While picking silhouette as the cheapest way to stay tuned up for elk seasons, I learned that keeping things under control at 600 yards wasn't going to be as easy as I first thought. I could get bullets cheap, and had easy access to powder and primers without much effort, but match quality brass was the same for all of us, difficult.

One could get mil-surp and commercial easy enough, but we are discussing state of the art match accuracy as it relates to today's brass. Uncle Sam was giving me as much used brass as I wanted but boy was it work to turn it into acceptable. Occasionally we could get virgin LC or "special" commercial brass, but it still wouldn't make you happy. It took tons of sorting and prep work.

We are far better off in terms of being able to purchase batches with tight quality controls than we have ever been. In today's world, we can go no-turn and no-sort and in most cases be competitive (depending on your context). That said...

The whole point of that story is the previous generation had typically been forced to learn the answers to the question of what matters in brass prep and what doesn't. That was by necessity.

I learned the hard way by getting burned. Some batches of brass were really bad, and others were really good. That experience taught me to test the question at hand, which is "when does the weight of a piece of brass from a batch create a flyer on the target or cause me to re-tune?"

For now, I don't sort, turn, or do any extraordinary prep for <600 because I sample screen fresh batches of brass. That is mostly Lapua to be specific and the reason is their QC is good enough for Midrange or Service Rifle. That hasn't been true of many other brands, in the past or even now. I can see the difference at 1000 so I admit to some more screens for those.

So I would suggest two things, one is to spend some time early in your life learning to sort/screen your components to learn what their typical stats are running. Learn to save the ones that are "off the tails of the curve" and store them till you can run tests. That may not come from one batch, but keep watching cause sooner or later there will be an escape.

By getting your own experience you will learn what that brand is typically giving you, and when it becomes a reject. The exact value isn't the same for every caliber or context. That doesn't mean you can't ask around within your area of interest, but that is trying to say that what works for F-Class may not work for Benchrest, the value for a 338 is different than the value for a 223, etc.

You will be far better off doing the work yourself over time than just taking my word for it. The motivation will come as a matter of time. Sooner or later, material shortages, tooling changes, brand substitutions, etc., will burn you on the target and you will want to know what just hit you... YMMV

@Topwater, Welcome to the rabbit hole! After jumping way down myself, I realized that by using quality brass and then weight sorting them in the beginning, I could skip the remainder of the tedious steps. However, I still needed to experience the rabbit hole on my own in order to let my mind find peace. Good luck in your adventures!

Similar threads

- Replies

- 22

- Views

- 6,084

- Replies

- 14

- Views

- 1,898

- Replies

- 81

- Views

- 9,284

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.