You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why 6mm ARC not 244 Valkyrie?

- Thread starter RustyPin

- Start date

Milspec for the 6MM ARC case was 52,000 PSI, at least that's what was released to the press. The original 5.56 NATO was 52,000 PSI.Mil spec for 5.56 is 55k isn't it? I thought the ARC was held to 52k because the increase in case size reduced bolt strength. If that's the case why should any comparison artificially handicap any cartridge that doesn't share this weakness?

It'sxwhat peaked my interest as at that pressure longevity should be easily obtained.

Thrust is figured by area of the case X the PSI, Any case with a diameter of the Grendel .442 will create more thrust on the bolt lugs. At 52000 psi the Grendel/ARC will create 8132lbs of thrust, the bolts strength has a safety ratio of 1.9. The 5.56 has a safety ratio of 3.9 when loaded to 62000psi. That is why we see many more failures of Grendel bolts than we do 5.56 bolts in AR15s. IF you use a 6mm ARC in a bolt gun, AK, Galil, Bren that is designed for the 7.62x39 then there is no problem with bolt thrust even at a higher pressure.Milspec for the 6MM ARC case was 52,000 PSI, at least that's what was released to the press. The original 5.56 NATO was 52,000 PSI.

It'sxwhat peaked my interest as at that pressure longevity should be easily obtained.

I don't feel Hornady is looking to do any harm to the 224 Valkyrie. IMHO For us reloader's the Arc cartridge does bury a rebated .244-Valkyrie / .24 Nosler due to brass life & external ballistics.

If you do not reload then the brass life may be a non issue.

Let's just say, I personally feel they got the ARC right. Then to be fair about my opinion I favor the 6mm ARC in a mini action, bolt action rifle. Relatively few of us who are appreciating the ARC in this roll. Perhaps Howa may change this going forward. For me a re-barreled 7.62 x 39 CZ527, to 6mm ARC is where the ARC really shines with a wide range of bullets to be reloaded.

Unfortunately we have been largly, left to fire forming 6.5 Grendel brass & 220 russian brass due to poor availability of the 6mm ARC brass.

If you do not reload then the brass life may be a non issue.

Let's just say, I personally feel they got the ARC right. Then to be fair about my opinion I favor the 6mm ARC in a mini action, bolt action rifle. Relatively few of us who are appreciating the ARC in this roll. Perhaps Howa may change this going forward. For me a re-barreled 7.62 x 39 CZ527, to 6mm ARC is where the ARC really shines with a wide range of bullets to be reloaded.

Unfortunately we have been largly, left to fire forming 6.5 Grendel brass & 220 russian brass due to poor availability of the 6mm ARC brass.

Despite the ARC outperforming the 24 Nosler just a tad, the SPC boltface is stronger in the AR Platform. Just how much can the ARC case outperform the Valk-Nosler Case in 6mm? Why didn't Hornady just come out with a "244-Valkyrie"? I have read the Brass was not holding up well, is Hornady out to bury the .224 Valkyrie? How good is the 24 Nosler to 1000 Yards?

I have both 2 6mm ARCs 18" Proof SS barrels and 24" 224 Valkyrie, All in AR 15 platform.

The Valkyrie was hard to get to shoot accurate in my AR, but I finally got it pretty good, after a barrel twist change.

The 6 ARC was horrible with the factory assembled upper...ordered a Proof Research SS barrel and assembled it myself...took them both to the range firing the same ammo 108 eldm, the factory upper 5 shots 2.5" about typical...then the Proof first 5 shot group was .5" (with the same ammo)..so I ordered another Proof barrel, and trashed the factory barrel and this new barrel has a slight edge over the first Proof barrel with the same ammo.

So my preference is the 6mm ARC for what I use it for, they are actually pretty close in performance in trajectory, with the long barrel the Valkyrie has a slight advantage but the Valkyrie has a heavy 24" barrel and the 6mm ARC a handy medium 18" barrel running 108 eldm at 2667 Ave small S/D some would be as low as 2.0 with thrown charges on the Dillon...and very accurate, especially for sn AR ...I have fire 58 gr to 115 DTAC in the ARC...even tried 6.5 Staball, but Leverevolution is the powder ...so far.The ARC advantage is heavy bullets same for the Valkyrie...for light varmint bullets just use the 223. The Valkyrie would have less performance in an 18" barrel then comparing it to the 18" ARC they would obtain similar velocities 88 gr to 108 gr ...the 108 with more energy, choices might come down to just accuracy.

And my notes on the Valkyrie have a lot of ,"not accurate" beside a load and much larger S/D in velocity. I changed the Valkyrie barrel, as my 6.5 twist was more accurate than 7 twist by alot, centered the bolt carrier another improvement then its small groups were on the lower velocity side but it had some nice groups...finally, but the lower velocity to get accuracy had no advantage over the 2 well shooting 6mm ARCs that were easy to shoot accurately on the top velocities for an AR and a lighter 18" barrel instead of a 24" So I set the Valkyrie aside and enjoyed the ARCs. But the Valkyrie has its place with the 80 to 95 gr bullets in the AR platform...and the last time out it put 5 95 gr MK into .458" & .470" with RL17 and "more jump" to the rifling. Surprise...It is what it is...

The Valkyrie was hard to get to shoot accurate in my AR, but I finally got it pretty good, after a barrel twist change.

The 6 ARC was horrible with the factory assembled upper...ordered a Proof Research SS barrel and assembled it myself...took them both to the range firing the same ammo 108 eldm, the factory upper 5 shots 2.5" about typical...then the Proof first 5 shot group was .5" (with the same ammo)..so I ordered another Proof barrel, and trashed the factory barrel and this new barrel has a slight edge over the first Proof barrel with the same ammo.

So my preference is the 6mm ARC for what I use it for, they are actually pretty close in performance in trajectory, with the long barrel the Valkyrie has a slight advantage but the Valkyrie has a heavy 24" barrel and the 6mm ARC a handy medium 18" barrel running 108 eldm at 2667 Ave small S/D some would be as low as 2.0 with thrown charges on the Dillon...and very accurate, especially for sn AR ...I have fire 58 gr to 115 DTAC in the ARC...even tried 6.5 Staball, but Leverevolution is the powder ...so far.The ARC advantage is heavy bullets same for the Valkyrie...for light varmint bullets just use the 223. The Valkyrie would have less performance in an 18" barrel then comparing it to the 18" ARC they would obtain similar velocities 88 gr to 108 gr ...the 108 with more energy, choices might come down to just accuracy.

And my notes on the Valkyrie have a lot of ,"not accurate" beside a load and much larger S/D in velocity. I changed the Valkyrie barrel, as my 6.5 twist was more accurate than 7 twist by alot, centered the bolt carrier another improvement then its small groups were on the lower velocity side but it had some nice groups...finally, but the lower velocity to get accuracy had no advantage over the 2 well shooting 6mm ARCs that were easy to shoot accurately on the top velocities for an AR and a lighter 18" barrel instead of a 24" So I set the Valkyrie aside and enjoyed the ARCs. But the Valkyrie has its place with the 80 to 95 gr bullets in the AR platform...and the last time out it put 5 95 gr MK into .458" & .470" with RL17 and "more jump" to the rifling. Surprise...It is what it is...

Not to be too pedantic, but the phrase is “for all intents and purposes.”Thanks for all the replies, but, just to be clear the only reason the the .224 Valk is really in the discussion is for it brass to be converted into 6mm, hence the 24 Nosler reference. Both are short SPC type cases that have been cut down in order to use the longer 6mm pills. Both Cartridges in question are .244".

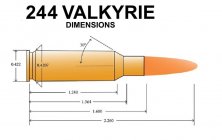

For all intensive purposes the 24 Nosler case is the same as the .224 Valk if it was necked up to .244. So yes, it does leave room for the longer Bullets, just not quite as much room as the ARC. The base of the neck on the ARC = 1.25 vs the 24 Nosler's 1.3 or .0472 difference to be exact. ARC listed case capacity is 36 gr H20 vs 34.5 for .224 Valk, or closer to 35.5 for a necked up .244 Valk case. So in realistic Terms for comparisons sake they are nearly identical with the ARC maybe getting a 1 gr advantage and the .047 height advantage. Also the .224 Valk case is rated for 3000 psi more than the ARC.

Please feel free to correct any negligent capacity differences..

Edit: I have no personal experience dealing with the 224 Valk, even the beginning post assumed it was Hornady who introduced the Valk, instead it was Federal. I somehow was lead to believe it was a Hornady Cartridge, my apologies.

I don't know if it's for All purposes, but I'd like to own one. The 244 Valkyrie that is.Not to be too pedantic, but the phrase is “for all intents and purposes.”

LVLAaron

Gold $$ Contributor

Numbers and measurements aside...

The Valkyrie was the hotness for about a month on the youtubes. It seemed like no one shot a group less than an inch. I still haven't seen anyone bragging on a really accurate Valkyrie.

6 Arc on the other hand... a tried and true cartridge design...

The Valkyrie was the hotness for about a month on the youtubes. It seemed like no one shot a group less than an inch. I still haven't seen anyone bragging on a really accurate Valkyrie.

6 Arc on the other hand... a tried and true cartridge design...

Last edited:

Not to get all hot and bothered but you should watch the video plastered in the link above. If it's good enough for Frank than it's good enough period. (There is no denying the weak Grendel Bolt in the AR's.)Numbers and measurements aside...

The Valkyrie was the hotness for about a month on the youtubes. It seemed like no one shot a group less than an inch. I still haven't seen anyone bragging on a really accurate Valkyrie.

6 Arc on the other hand... a tried and true cartridge design...

LVLAaron

Gold $$ Contributor

Not to get all hot and bothered but you should watch the video plastered in the link above. If it's good enough for Frank than it's good enough period. (There is no denying the weak Grendel Bolt in the AR's.)

Agree the bolt is weak. I can't stand that guy, so I'll pass on the video.

White Eagle

Silver $$ Contributor

if you want a 6mm get one

I have a Valkyrie and have had no issues with it

sounds like a lot are saying "well I heard this or that", without any personal experience

some like 6mm's some like 224's

I have a Valkyrie and have had no issues with it

sounds like a lot are saying "well I heard this or that", without any personal experience

some like 6mm's some like 224's

I have broken several 6.5 Grendel bolts due to the weakened state of the bolts to accommodate the wide shell. I'd have gone rebated rim. I do shoot the rebated rim in my .22 Nosler A/R and have had zero issues with brass, nor have any of my friends had problems of any kind. We shoot Nosler brass and Dogtown brass (also made by Nosler). No issues. That brass is some beefy stuff. When you get a handful of guys complaining about short brass life when there is a new cartridge out - the cartridge gets a bad rap. Now that it has been out a while - and many are shooting it - you don't hear of those "problems" so much.We can guess. Rebated rims in semi-auto rifles are generally not done because of poor reliability.

And if you've been monitoring the 22 Nosler and Valkyrie, you'll observe they widely are reported to have brass issues. 22 Nosler in particular.

Rebated rims are fine in a bolt/pump gun that won't be fed from a box magazine or aren't even a repeater.

Ever wonder why rebated rims are seemingly never used in any military round?

If I may ask - when did you break your Grendel bolts, and who had made them? At one time, breaking bolts in 6.5 Grendel was a significant item of note. Until it wasn't. Today, nobody seems to be breaking a current production Grendel bolt - despite some pretty strong loads it seems some folks run. My suspicion, with little more than conjecture, is that the metallurgy and practices have gotten better, and broken bolts are mostly a thing of the past - almost unheard of to see a broken-bolt thread these days with Grendel. But I could be wrong, so I'm curious when yours broke.I have broken several 6.5 Grendel bolts due to the weakened state of the bolts to accommodate the wide shell. I'd have gone rebated rim. I do shoot the rebated rim in my .22 Nosler A/R and have had zero issues with brass, nor have any of my friends had problems of any kind. We shoot Nosler brass and Dogtown brass (also made by Nosler). No issues. That brass is some beefy stuff. When you get a handful of guys complaining about short brass life when there is a new cartridge out - the cartridge gets a bad rap. Now that it has been out a while - and many are shooting it - you don't hear of those "problems" so much.

As to 6mm ARC. I think 6mm PPC is a fantastic target round. Personally, I prefer 6.5 Grendel because it does stuff when it hits stuff. Bill Alexander designed 6.5 Grendel, because 6mm PPC (which is 6mm ARC - for all practical purposes), doesn't hit stuff hard enough to kill stuff as well as Grendel does - at the ranges a mortal is likely to shoot. Obviously there will be many postings of great kills, which is awesome. but the point is 6.5 Grendel shoots a heavier bullet to do more stuff, and so with that, is more forgiving for that imperfectly placed shot, than a target bullet is. To me, 6.5 Grendel is an excellent 300 yard hunting round, that's a pretty darned good 800 yard gong-range round, that can do 1000 yards OK enough. Whereas 6mm ARC is a good 800-1000 yard gong range round, that's a decent'ish 300 yard hunting round. 6mm ARC is arguably a better military round, in that hits matter more than lethality, and if shooting at bad guys at 1000 yards, a 6mm ARC has slightly better odds of connecting, than a 6.5 Grendel. While 6.5 Grendel is the better 300 yard round, IMHO; but a hit is an incapacitation is a hit, in Military settings, moreso than I need a drop dead kill, in hunting application. Me - I'm more interested in a good hit capability as well as killing stuff I shoot at, and ringing gongs I connect with, than I am in a slightly higher fast shoot 1000 yard hit capability.

While many people celebrate 6mm ARC as an ideal round, I personally don't. I consider 6.5 Grendel the better choice as the ideally optimized round for the AR15 platform. That's me - by all means, please enjoy what you enjoy without bother from some blowhard on the InterWebs, of course.

I have broken at least three 6.5 Grendel bolts. It is always one or two of the "teets" crack at the base, where they join the face of the bolt - and adjacent to the extractor. The first two were Alexander Arms bolts, the third I cannot recall - but was a different manufacture - a nice hardened bolt, Magnetic inspection for flaws, etc. as are most good bolts. I'll admit I ran those bolts hard with high pressure - but those bolts would not have broken had so much material not been removed from the bolt to make way for that wide case. While I was running them at the top of the powder spectrum as prescribed by the manuals - I wasn't exceeding those published numbers and there were no pressure signs on the brass. If you look at many of the manuals that first published Grendel load data - and compare them to current data, the latter tends to show slightly less max on the loads. So - I'm of the mind that there wasn't so much of a dramatic improvement in metallurgy in the past 5-10 years - it was because everyone recognized the limitations of the cartridge and loaded down. Right or wrong - that is my thought. I sense you might think I was putting down the Grendel in some way because of that. Quite the contrary. I personally wouldn't make comparisons between the 6PPC and the Grendel for hunting though. There simply is no comparison - and these cartridges were designed for entirely different purposes. I love my PPC's - but I'd never take them to go shoot anything I need a Grendel to do. I shoot 120's in my Grendel and 65's in my PPC. My points were meant to take aim at whether having no meat on the business end of the bolt was better or worse than the pros and cons of a rebated base piece of brass. I'll take premature brass failure over sudden bolt failure. No doubt, folks who run their Grendel well below max loads will not likely encounter the ills I did. If you run them at the top - and you shoot them a lot - you will likely have one fail at some point. A lot of folks say the military didn't choose the Grendel due to the patented name, etc. - but the Grendel is not a military-tough cartridge, plain and simple. The bolt is the weak point of the rifle. That said, I love mine. My favorite "heavy" A/R is a Grendel that easily shoots 1/3" MOA with Scenars and shoots the Barnes TSX's almost as well. I just take care to not run to the top anymore - or even close.If I may ask - when did you break your Grendel bolts, and who had made them? At one time, breaking bolts in 6.5 Grendel was a significant item of note. Until it wasn't. Today, nobody seems to be breaking a current production Grendel bolt - despite some pretty strong loads it seems some folks run. My suspicion, with little more than conjecture, is that the metallurgy and practices have gotten better, and broken bolts are mostly a thing of the past - almost unheard of to see a broken-bolt thread these days with Grendel. But I could be wrong, so I'm curious when yours broke.

As to 6mm ARC. I think 6mm PPC is a fantastic target round. Personally, I prefer 6.5 Grendel because it does stuff when it hits stuff. Bill Alexander designed 6.5 Grendel, because 6mm PPC (which is 6mm ARC - for all practical purposes), doesn't hit stuff hard enough to kill stuff as well as Grendel does - at the ranges a mortal is likely to shoot. Obviously there will be many postings of great kills, which is awesome. but the point is 6.5 Grendel shoots a heavier bullet to do more stuff, and so with that, is more forgiving for that imperfectly placed shot, than a target bullet is. To me, 6.5 Grendel is an excellent 300 yard hunting round, that's a pretty darned good 800 yard gong-range round, that can do 1000 yards OK enough. Whereas 6mm ARC is a good 800-1000 yard gong range round, that's a decent'ish 300 yard hunting round. 6mm ARC is arguably a better military round, in that hits matter more than lethality, and if shooting at bad guys at 1000 yards, a 6mm ARC has slightly better odds of connecting, than a 6.5 Grendel. While 6.5 Grendel is the better 300 yard round, IMHO; but a hit is an incapacitation is a hit, in Military settings, moreso than I need a drop dead kill, in hunting application. Me - I'm more interested in a good hit capability as well as killing stuff I shoot at, and ringing gongs I connect with, than I am in a slightly higher fast shoot 1000 yard hit capability.

While many people celebrate 6mm ARC as an ideal round, I personally don't. I consider 6.5 Grendel the better choice as the ideally optimized round for the AR15 platform. That's me - by all means, please enjoy what you enjoy without bother from some blowhard on the InterWebs, of course.

Fast14riot

Gold $$ Contributor

Aside from the accuracy issues with the 224 Valkyrie, as a long time 6.8spc shooter (in competition, too) I have found that there is a huge difference in brass. Hornady 6.8 brass was one of the worst for being soft, loosing primer pockets, etc. However, the S&B produced Hornady stamped brass (yes, Sellier& Bellot produced 6.8spc ammo for Hornady), as well as S&B stamped brass is excellent. Add in the mix between LRP and SRP, cheap brass like Federal and it became a pain to get good brass.

Most guys who are having brass problems are doing so because they are loading them on the very hot spectrum. These can't be "over loaded" like a PPC or Dasher. I and a lot of friends run 22 Noslers (which had the worst "rap", and we get just as many loadings out of them as with a .223 in an A/R. There may have been some early brass problems due to brass production, but we have not encountered them in any way. We use Nosler and Dogtown brass (also made by Nosler). I much prefer the rebated rims - as I like knowing there is a little more meat on the bolt. Have wasted a number of bolts on the Grendel cartridge - and I expect I'd do the same on the other rounds which require "extreme" bolt face removal to get the brass to fit. The rebated rims aren't used in military rounds because the gun is built around the cartridge. A lot of guys talk trash on these rounds - and have never owned them.We can guess. Rebated rims in semi-auto rifles are generally not done because of poor reliability.

And if you've been monitoring the 22 Nosler and Valkyrie, you'll observe they widely are reported to have brass issues. 22 Nosler in particular.

Rebated rims are fine in a bolt/pump gun that won't be fed from a box magazine or aren't even a repeater.

Ever wonder why rebated rims are seemingly never used in any military round?

I built myself a 308 gas gun using the Aero M5 receiver set, so I’m gtg now on everything I’d want to do with a bit more power in the AR world. The Toolcraft bolt has lots of meat on it and the dual ejector model has the reduced firing pin ala JP high pressure bolt. It’s a great BCG for this kind of rifle. Perfect function.

Similar threads

- Replies

- 2

- Views

- 3,940

- Replies

- 58

- Views

- 14,815

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.