If you run a 10 Round Load Development Ladder Test will your node typically be around the same powder charge if you reduce/increase your seating depth?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Velocity node question?

- Thread starter Devildog0311

- Start date

It has been my experience that seating depth will "move the ladder", but not to the magnitude of powder weight. I would really like to see this thread develop - it is a very interesting concept.

Does seating depth have an effect on velocity?

Does seating depth have an effect on velocity?

30 BR Depth Test

This was shot starting at .018 out of hard jam and moved in to .004 out of hard jam. The velocity increased slightly and then stopped increasing as I could feel the difference in depth when closing the bolt on the last 3 targets. The sample is small but the ES was good so this may help answer the question about velocity increase. I really don't like 3 shot groups as they tend to produce less than accurate results so take this for what it is worth.

This was shot starting at .018 out of hard jam and moved in to .004 out of hard jam. The velocity increased slightly and then stopped increasing as I could feel the difference in depth when closing the bolt on the last 3 targets. The sample is small but the ES was good so this may help answer the question about velocity increase. I really don't like 3 shot groups as they tend to produce less than accurate results so take this for what it is worth.

wvlongshot

Gold $$ Contributor

30 BR Depth Test

This was shot starting at .018 out of hard jam and moved in to .004 out of hard jam. The velocity increased slightly and then stopped increasing as I could feel the difference in depth when closing the bolt on the last 3 targets. The sample is small but the ES was good so this may help answer the question about velocity increase. I really don't like 3 shot groups as they tend to produce less than accurate results so take this for what it is worth.

View attachment 1245819

Are these targets available for sale?

XL105

Silver $$ Contributor

FREE Targets for Load Development, Training, and Fun Shooting « Daily Bulletin

Here's an early Christmas present to our readers -- a selection of FREE printable precision and fun targets. You can download these targets as PDF files and then print them out on 8.5x11 heavy paper. AccurateShooter.com offers a cool page with over <a href=https://www.accurateshooter.

Here are free targets on accurateshooter.

The downloadable PDF files are available free on brflags.comAre these targets available for sale?

Benchrest Shooting Resources » Graham Wind Flags

Graham Wind Flags Resources: Links to Other Resources:

D-4297

Gold $$ Contributor

In my testing , the velocity increases weren't enough to change the node data , as I seated the bullet towards more "jump" . I don't Jam anything so I have no idea on that . Only when I got to the 200.20x , and a heavier powder load , did I see noticeable velocity change , but not enough to go to a higher node . Halfway , maybe ?

RegionRat

Gold $$ Contributor

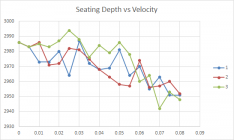

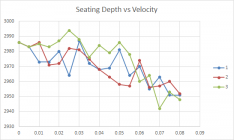

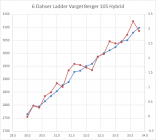

A typical 6 Dasher with a new bbl running a Berger 105 Hybrid with an identical charge weight showing velocity at the muzzle on the vertical axis and seating depth on the horizontal axis. Three strings of the same test. From touching to 80 thousandths jump went from 2986 to 2950.

For perspective, some folks consider 80 thousandths to be a lot of jump, and others don't.

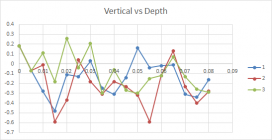

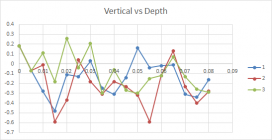

Here are the verticals at 600 yards for those same runs. The vertical dimension of the entire test spans -0.6 to +0.25 MOA or 0.85 MOA top to bottom for a seating depth spread from touch to 0.080" jump.

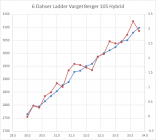

Here was the first string that was run for charge weight using an arbitrary jump of 0.015" just as an easy starting point. I took 31.9 grains of Varget and went with it for those tests above. The blue line is the velocity with the left scale, the red line is the vertical at 600 yards in MOA on the right scale. Positive compensation from about 31.5 to 32.5 grains, which explains my 31.9 above.

My conclusion is that if I start with seating depth of about 0.030" jump, I can let it wear for about 0.025" before I need to check it again. What I don't want to do, is start it at 0.015 jump, because it will then open up to about 1/2 MOA before it drops again.

I shoot sling, so anything under 0.4 MOA is good enough for low effort.

ETA: somebody asked to show the target for the ladder run, so hear is what that looks like. No attempt at wind, just hold the X and pull the trigger. Shot number 10 would be 31.8 grains for reference.

For perspective, some folks consider 80 thousandths to be a lot of jump, and others don't.

Here are the verticals at 600 yards for those same runs. The vertical dimension of the entire test spans -0.6 to +0.25 MOA or 0.85 MOA top to bottom for a seating depth spread from touch to 0.080" jump.

Here was the first string that was run for charge weight using an arbitrary jump of 0.015" just as an easy starting point. I took 31.9 grains of Varget and went with it for those tests above. The blue line is the velocity with the left scale, the red line is the vertical at 600 yards in MOA on the right scale. Positive compensation from about 31.5 to 32.5 grains, which explains my 31.9 above.

My conclusion is that if I start with seating depth of about 0.030" jump, I can let it wear for about 0.025" before I need to check it again. What I don't want to do, is start it at 0.015 jump, because it will then open up to about 1/2 MOA before it drops again.

I shoot sling, so anything under 0.4 MOA is good enough for low effort.

ETA: somebody asked to show the target for the ladder run, so hear is what that looks like. No attempt at wind, just hold the X and pull the trigger. Shot number 10 would be 31.8 grains for reference.

Last edited:

Excellent write up. Thank you for posting this.A typical 6 Dasher with a new bbl running a Berger 105 Hybrid with an identical charge weight showing velocity at the muzzle on the vertical axis and seating depth on the horizontal axis. Three strings of the same test. From touching to 80 thousandths jump went from 2986 to 2950.

For perspective, some folks consider 80 thousandths to be a lot of jump, and others don't.

View attachment 1246026

Here are the verticals at 600 yards for those same runs. The vertical dimension of the entire test spans -0.6 to +0.25 MOA or 0.85 MOA top to bottom for a seating depth spread from touch to 0.080" jump.

View attachment 1246027

Here was the first string that was run for charge weight using an arbitrary jump of 0.015" just as an easy starting point. I took 31.9 grains of Varget and went with it for those tests above. The blue line is the velocity with the left scale, the red line is the vertical at 600 yards in MOA on the right scale. Positive compensation from about 31.5 to 32.5 grains, which explains my 31.9 above.

View attachment 1246028

My conclusion is that if I start with seating depth of about 0.030" jump, I can let it wear for about 0.025" before I need to check it again. What I don't want to do, is start it at 0.015 jump, because it will then open up to about 1/2 MOA before it drops again.

I shoot sling, so anything under 0.4 MOA is good enough for low effort.

ETA: somebody asked to show the target for the ladder run, so hear is what that looks like. No attempt at wind, just hold the X and pull the trigger. Shot number 10 would be 31.8 grains for reference.

View attachment 1246029

I ran some tests with QuickLoad and found that changing the jump has a similar result as changing the load. Over a small change like +/- 1 % it was a similar amount.

I did this as I always felt that adjusting the jump did nothing more than changing the load a bit. I don't believe that different barrels "Like" one jump more than another. "like" is not a term engineers agree on!

I tune my new barrels (after breaking them in) by shooting 5 5shot groups in round robin fashion. I record Mv

and find the avg. Mv as well as Es. I don't have to shoot at a target as I am getting Mv data. Then I plot it in EXCEL and do a 4th order polynomial curve fit to find the real curve and pick the powder load for lowest Es. I use a barrel tuner so then I shoot groups with adjustments till I find the best group.

If you don't use a tuner, you may want to shot groups with the different loads and plot group sizes , do a curve and a 4th order polynomial on that data to find best load.

I did this as I always felt that adjusting the jump did nothing more than changing the load a bit. I don't believe that different barrels "Like" one jump more than another. "like" is not a term engineers agree on!

I tune my new barrels (after breaking them in) by shooting 5 5shot groups in round robin fashion. I record Mv

and find the avg. Mv as well as Es. I don't have to shoot at a target as I am getting Mv data. Then I plot it in EXCEL and do a 4th order polynomial curve fit to find the real curve and pick the powder load for lowest Es. I use a barrel tuner so then I shoot groups with adjustments till I find the best group.

If you don't use a tuner, you may want to shot groups with the different loads and plot group sizes , do a curve and a 4th order polynomial on that data to find best load.

Ccrider

Gold $$ Contributor

Dang. Just when I thought I was beginning to understand. I got to go back to schoolI ran some tests with QuickLoad and found that changing the jump has a similar result as changing the load. Over a small change like +/- 1 % it was a similar amount.

I did this as I always felt that adjusting the jump did nothing more than changing the load a bit. I don't believe that different barrels "Like" one jump more than another. "like" is not a term engineers agree on!

I tune my new barrels (after breaking them in) by shooting 5 5shot groups in round robin fashion. I record Mv

and find the avg. Mv as well as Es. I don't have to shoot at a target as I am getting Mv data. Then I plot it in EXCEL and do a 4th order polynomial curve fit to find the real curve and pick the powder load for lowest Es. I use a barrel tuner so then I shoot groups with adjustments till I find the best group.

If you don't use a tuner, you may want to shot groups with the different loads and plot group sizes , do a curve and a 4th order polynomial on that data to find best load.

jelenko

Gold $$ Contributor

4th order polynomial? of what?I ran some tests with QuickLoad and found that changing the jump has a similar result as changing the load. Over a small change like +/- 1 % it was a similar amount.

I did this as I always felt that adjusting the jump did nothing more than changing the load a bit. I don't believe that different barrels "Like" one jump more than another. "like" is not a term engineers agree on!

I tune my new barrels (after breaking them in) by shooting 5 5shot groups in round robin fashion. I record Mv

and find the avg. Mv as well as Es. I don't have to shoot at a target as I am getting Mv data. Then I plot it in EXCEL and do a 4th order polynomial curve fit to find the real curve and pick the powder load for lowest Es. I use a barrel tuner so then I shoot groups with adjustments till I find the best group.

If you don't use a tuner, you may want to shot groups with the different loads and plot group sizes , do a curve and a 4th order polynomial on that data to find best load.

JELENKO,

In EXCEL I plot a curve of Mv vs Load weight. This yields a curve of the transfer equation of Mv vs load. Then I drop over and look for trending and click other and I can convert the above transfer equation into a 4th (or 5th order polynomial equation of the actual equation of Mv vs load with much more accuracy.

In my case, the first plot showed the lowest ES was at 30.5 gr. By doing an exact equation ( to a 4th or 5th

order). The original plot only connects the discrete data points and the curve fitting part of EXCEL finds the best 4th order polynomial equation solution. This told me the actual node was 30.55gr and ES was slightly lower than the 30.5 data point.

This is important to me as My lab balance (on gram scale) is accurate to .015 gr where on grains it truncates to 0.020gr

In EXCEL I plot a curve of Mv vs Load weight. This yields a curve of the transfer equation of Mv vs load. Then I drop over and look for trending and click other and I can convert the above transfer equation into a 4th (or 5th order polynomial equation of the actual equation of Mv vs load with much more accuracy.

In my case, the first plot showed the lowest ES was at 30.5 gr. By doing an exact equation ( to a 4th or 5th

order). The original plot only connects the discrete data points and the curve fitting part of EXCEL finds the best 4th order polynomial equation solution. This told me the actual node was 30.55gr and ES was slightly lower than the 30.5 data point.

This is important to me as My lab balance (on gram scale) is accurate to .015 gr where on grains it truncates to 0.020gr

I also looked at the data from my quickload experiment of changes in Mv and Bt vs jump and load weight.

As I use the curves I generate from testing load vs Es, I found that a 0.3 gr change of load yields a barrel time change of 0.018ms (from 1.341ms.) and 0.05in change in jump yielded 0.018ms change (from 1.341ms.

As I am looking for the load with the lowest ES, I am actually looking for a barrel time which is proportional to longitudinal resonance frequency. This yields a resonance that forces the bullet to have minimum change in velocity over a very slight load change.

Or, if you don't use a tuner as I do, you would test for group size instead of ES.

As I use the curves I generate from testing load vs Es, I found that a 0.3 gr change of load yields a barrel time change of 0.018ms (from 1.341ms.) and 0.05in change in jump yielded 0.018ms change (from 1.341ms.

As I am looking for the load with the lowest ES, I am actually looking for a barrel time which is proportional to longitudinal resonance frequency. This yields a resonance that forces the bullet to have minimum change in velocity over a very slight load change.

Or, if you don't use a tuner as I do, you would test for group size instead of ES.

Mistakes abound where grams are mentioned as grains. g or gr ...don't get them mixed up !Can someone translate to farm boy speak?

Calculation of tractor fuel cost,based on say the number of corn rows planted in two different shaped fields.Can someone translate to farm boy speak?

What concerned me more was,I did understand it(sorta).... having not made it very far in school.

Similar threads

- Replies

- 32

- Views

- 7,248

- Replies

- 21

- Views

- 3,959

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.