Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Velocity Extreme Spread and Standard Deviation

- Thread starter chkunz

- Start date

I am not sure if the ES or SD numbers are affected by it. But I know in longrange the groups are affected by it. I was also told by the shortrange shooters that the groups are affected by it also. I have no experience with the shortrange game, but I have a lot at distance.

The firing pin has to hit the primer before it can be set off. There is no way a bullet can be out the barrel before the primer is set off. Matt

The firing pin has to hit the primer before it can be set off. There is no way a bullet can be out the barrel before the primer is set off. Matt

I am not sure if the ES or SD numbers are affected by it. But I know in longrange the groups are affected by it. I was also told by the shortrange shooters that the groups are affected by it also. I have no experience with the shortrange game, but I have a lot at distance.

The firing pin has to hit the primer before it can be set off. There is no way a bullet can be out the barrel before the primer is set off. Matt

I think you misunderstood what I was saying, or I did a bad job of explaining it. I left it to reason that given both rifles {short action Model 700's}, same everything with the exception that one has a Speedlock firing pin and Wolf spring...break the sear at exactly the same time. From that point, of which the sear is broken the bullet is out of the muzzle and unaffected by any further movement in the gun BEFORE the primer gets hit in the rifle without the Speedlock kit. Milliseconds. But a lot can happen in a millisecond when we are talking these kinds of speeds. I have always heard this, don't know if it is true, never tried to prove it, but it is measurable. Now, given that if it is true you are saying go the opposite way and slow things down even more...it seems like less time for movement in the rifle could enhance accuracy, but you say no, add time and it's more accurate. I believe repeatable primer ignition could enhance accuracy too, no argument here...but how do you prove it or know that is the cause or lack of????? I'll agree, it all sounds good.

Dusty Stevens

Shiner

The only way to prove it is to do the pepsi challenge. That solid hard hit of mass is what primers need- kinetic energy. Ive never seen a speedlock or light pin make a gun shoot a smaller group- hell ive never seen one shoot the same size its always bigger. You could always start a poll on here and see for yourself. Or you can ask any successful br shooter, long range br shooter, or competition gunsmith- i bet theyve all fixed broken guns by removing speedlocks.

Recently a friend had been trying all sorts of things to get his ES down. Nothing seemed to do the trick until he tried another primer. So often I see shooters flogging the same old combination of components to death. I tend to tell them to stop trying harder, that instead they should try something different.

Boyd,Recently a friend had been trying all sorts of things to get his ES down. Nothing seemed to do the trick until he tried another primer. So often I see shooters flogging the same old combination of components to death. I tend to tell them to stop trying harder, that instead they should try something different.

What is your "go to" small rifle magnum primer for 6BR/Dasher?

CharlieNC

Gold $$ Contributor

Discussion often revolves around how many data points is necessary to obtain a meaningful answer, and this is a major point so as not to be misled making false conclusions. There is not a fixed answer for this, but following Donovan's example I will put together an excel file to share where you can enter your sets of chrono data and it will tell you if there is a statistical difference in variability (or not).Just 20 ? That is not enough. Larry

The more input the better the stats. LarryDiscussion often revolves around how many data points is necessary to obtain a meaningful answer, and this is a major point so as not to be misled making false conclusions. There is not a fixed answer for this, but following Donovan's example I will put together an excel file to share where you can enter your sets of chrono data and it will tell you if there is a statistical difference in variability (or not).

Don't shoot either of those. I am mostly a PPC guy, and we don't worry much about ES. I have a large variety of primers and have been able to work up loads with most of them. My friend is working with a .308 and had been working with federal primers. The switch that I mentioned was to Wolf , which, going forward may not be available for political reasons. I am a great advocate of experimenting. Often people seem to think that they can research stuff and skip the trial and error. I tend to work differently, preferring to do my own work.Boyd,

What is your "go to" small rifle magnum primer for 6BR/Dasher?

CharlieNC

Gold $$ Contributor

True, but you reach the point of diminishing return where more tests is a waste of money. I learned to live this in industry 45 years ago.The more input the better the stats. Larry

None of mine is wasted we have Ben testing our and others tuners . While testing we always record the speed . We try different bullet and powdes and primers. After 4 years and 30,000 rebounds . We have earned alot. Capacity of cases is what makes for low Es&SD . LarryTrue, but you reach the point of diminishing return where more tests is a waste of money. I learned to live this in industry 45 years ago.

dmoran

Donovan Moran

Charlie -

Sure wish barrel heat, fouling, wear, and ambient variance wouldn't effect the data out comes of our test sessions, like they do.

Then add in the expense to components and the time and expense to prepare creditable ammo and to conduct tests, further hinders how many liable rounds should be fired for sample size.

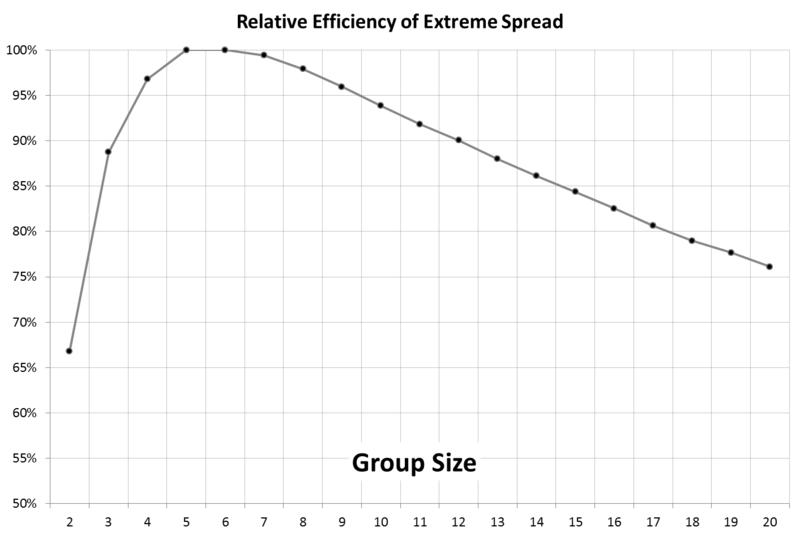

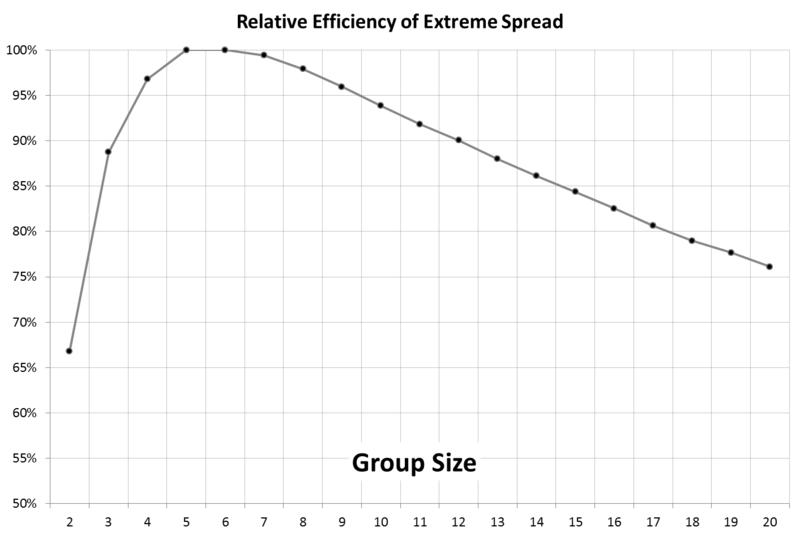

Do to the above mentioned hindrances, expenses, and labor, it is always my goal to efficiently use the least number of shots as possible to group size and ladder size. That has always been a reason why I base most my discovery on ES, since typically I'm using relatively small samples for statistical aspects. With vertical dispersion spreads (ES) on the targets, at target distance, being the most important data point I myself look at and judge by. Below is a "Relative Efficiency of Extreme Spread" by group size, ballistipedia chart.

Sure wish barrel heat, fouling, wear, and ambient variance wouldn't effect the data out comes of our test sessions, like they do.

Then add in the expense to components and the time and expense to prepare creditable ammo and to conduct tests, further hinders how many liable rounds should be fired for sample size.

Do to the above mentioned hindrances, expenses, and labor, it is always my goal to efficiently use the least number of shots as possible to group size and ladder size. That has always been a reason why I base most my discovery on ES, since typically I'm using relatively small samples for statistical aspects. With vertical dispersion spreads (ES) on the targets, at target distance, being the most important data point I myself look at and judge by. Below is a "Relative Efficiency of Extreme Spread" by group size, ballistipedia chart.

Last edited:

CharlieNC

Gold $$ Contributor

Donovan I had skimmed that article some time back regarding group sizes. In the case of comparing chrono data for the purpose of determining whether an improvement has been made, the statistics are very straightforward based on standard deviations; this is a much more robust statistic than ES. Of course ES is the measure of group size for many competitions, but on the other hand scoring as in F class is pretty much a graphical representation of the SD. I will email you the chrono calc program when I finish to get your input regarding what else to add before posting.

This is interesting to me. I'm not a metallurgist either; however, I did attend a number of metallurgy classes during my formal education as an engineer. Of course, one of the metals we studied was brass. Now, many years later, I find myself enjoying the shooting sports including hand loading, so I find myself once again studying brass since I anneal all my cases.Not a metallurgist, so I may not be explaining this correctly, but...brass will harden just from sitting. Unlike most metals brass gets harder just over time. There is probably some "molecular level" change or better explainable reason for it, but I never got quite that far into it other than to know that it seems like time alone will make brass hard. I am not sure why it is referred to as "air" hardening, other than it is just sitting in air??? I believe if I remember right that air hardened brass to a point can be annealed back to being as soft as the alloy can be or will allow. There is also a point over time that it cannot be recovered by annealing.

........ snip..............

I'm aware that there are some alloys of copper known as "precipitation hardening alloys" used mainly where particular electrical or thermodynamic properties are important. These alloys often contain metals other than zinc such as chromium, beryllium, nickel, silicon, and zirconium. While some aluminum alloys are precipitation hardened at ambient temperatures, as far as I know copper alloys are normally precipitation hardened at elevated temperatures of several hundred degrees. This is often called "age" hardening since it happens over a relatively long period of time, but not at room temperature.

But the point is moot since the brass we use is a simple copper/zinc alloy in the proportions of 70%/30%; commonly called "cartridge brass" for obvious reasons. It is not one of the precipitation hardening alloys.

Once again I must emphasize that although my formal training in metallurgy was more than most college students receive, it did not qualify me to be called a metallurgist. However, as far as I know, our cartridge brass will not become harder with age.

If I am wrong, and cartridge brass indeed becomes harder with age, I would appreciate someone pointing me to a scientific study. Surely if this were true, someone has studied this phenomenon and reported on it along with the mechanism causing it. Copper alloys have been around since the end of the stone age and I would guess have received more study than any other metal. If ordinary 70/30 brass got harder over a period of years by just sitting on the shelf, I would have thought this would have become common knowledge.

Apparently there is some anecdotal evidence that old cartridges can develop cracks. I suspect these cracked cartridge cases are the result of what is called "stress corrosion cracking". It can occur in several metals, brass being one of them, if they are simultaneously subjected to stress and chemical attack. This is not the same thing as "age" hardening, but I can see how someone might mistakenly think that cartridge case neck cracks could be caused by hardening of the brass.

As far as the term "air hardening", I am only familiar with that term as it applies to certain steels which can be hardened by cooling in air. In other words, unlike some steel alloys which are quenched in oil or water, "air hardening" steels are cooled from above their transformation temperature by simply allowing them to cool down in ordinary ambient air. But the hardening of steel is completely different from the way brass is hardened.

1shot

Gold $$ Contributor

Back in 2007 I think I jumped on the Tubb band wagon when the 6XC was new, along with T-2000 and several other of his ideas. I had a Rem. 700 re-barreled and chambered in 6XC. Right out of the gate using Tubbs loads it shot 1/4 moa @100 yds. with 4 different primers and the same load. I was really stoked! So, i go to his catalog thinking if his stuff is this good, let see what else he has. Yep, I bought on of those springs and pins. My groups instantly went to patterns with the same loads. After a talk with my rifle smith he told me the Rem. didn't spend over 2 mil. dollars in develop of their fire control system for nothing. Take that pin out and pawn it to someone else. It was magic I tell ya, patterns back to groups.Maybe not scientific by some standards but the proof is in the target.

Lloyd

Lloyd

I don't know what to think about firing pins. I tend to leave good enough alone, but John Pierce and Greg Tannel seem to know what they are doing and they sell a whiz bang firing pin setup. Granted, I'm not sure they are going to help my groups over a properly functioning factory setup. I think Gre-Tan's description of how a factory spring rides in the bolt body vs. the benefit of his setup has some merit to it.

This is interesting to me. I'm not a metallurgist either; however, I did attend a number of metallurgy classes during my formal education as an engineer. Of course, one of the metals we studied was brass. Now, many years later, I find myself enjoying the shooting sports including hand loading, so I find myself once again studying brass since I anneal all my cases.

I'm aware that there are some alloys of copper known as "precipitation hardening alloys" used mainly where particular electrical or thermodynamic properties are important. These alloys often contain metals other than zinc such as chromium, beryllium, nickel, silicon, and zirconium. While some aluminum alloys are precipitation hardened at ambient temperatures, as far as I know copper alloys are normally precipitation hardened at elevated temperatures of several hundred degrees. This is often called "age" hardening since it happens over a relatively long period of time, but not at room temperature.

But the point is moot since the brass we use is a simple copper/zinc alloy in the proportions of 70%/30%; commonly called "cartridge brass" for obvious reasons. It is not one of the precipitation hardening alloys.

Once again I must emphasize that although my formal training in metallurgy was more than most college students receive, it did not qualify me to be called a metallurgist. However, as far as I know, our cartridge brass will not become harder with age.

If I am wrong, and cartridge brass indeed becomes harder with age, I would appreciate someone pointing me to a scientific study. Surely if this were true, someone has studied this phenomenon and reported on it along with the mechanism causing it. Copper alloys have been around since the end of the stone age and I would guess have received more study than any other metal. If ordinary 70/30 brass got harder over a period of years by just sitting on the shelf, I would have thought this would have become common knowledge.

Apparently there is some anecdotal evidence that old cartridges can develop cracks. I suspect these cracked cartridge cases are the result of what is called "stress corrosion cracking". It can occur in several metals, brass being one of them, if they are simultaneously subjected to stress and chemical attack. This is not the same thing as "age" hardening, but I can see how someone might mistakenly think that cartridge case neck cracks could be caused by hardening of the brass.

As far as the term "air hardening", I am only familiar with that term as it applies to certain steels which can be hardened by cooling in air. In other words, unlike some steel alloys which are quenched in oil or water, "air hardening" steels are cooled from above their transformation temperature by simply allowing them to cool down in ordinary ambient air. But the hardening of steel is completely different from the way brass is hardened.

I get what you are saying and no argument here...but how do you explain brass cases that sit and get hard and then need to be annealed. I had a guy give me a whole load of empty, once fired lake City 58 308 brass. They pulled so hard over the expander ball that headspace length at the shoulder datum line increased. The cases actually pulled longer they were so hard. I was unable to use them as they were. I called the guy and he said, "I never did anything with those cases...all they did was sit in the bag since I got them 30 some odd years ago." Annealing made those cases so they were able to be reloaded and they shot great. Okay, they didn't "air harden" or any other name you want to hang on it...so what happened to cause this??? Something sure did, if I don't have the right name or am not calling it the correct thing, help me out please. I for sure do have the cure...annealing.

I get what you are saying and no argument here...but how do you explain brass cases that sit and get hard and then need to be annealed. ....... snip...........

Well, I'm not sure it is I who needs to explain this phenomenon since I say it doesn't happen and I can find no scientific evidence that it does happen. It is you making the claim, not I.

If cartridge brass hardened with age; i.e. simply sitting on the shelf at ambient temperatures, this property of the metal should be well known, especially since brass is hardly a new invention.

There is plenty of data on problems such as dezincification. The loss of zinc from brass in a saltwater environment (resulting in a spongy, low strength component) has caused boats to sink when a brass fitting was used below the waterline in place of the more appropriate bronze fitting. And there is lots of data related to stress corrosion cracking as well. But I can find nothing about "age" hardening of cartridge brass.

The fact that you had some old cases which were difficult to size and they became easier to size after you annealed them is certainly not the same thing as proving that they got harder just sitting around. I'm assuming you did not test the hardness of the old brass you encountered. It should be noted that plenty of people report on this forum and others that they have reloaded very old brass which reacted normally. Why did their brass not get hard over time if it is a natural property of the metal?

I believe Elvis is dead, but there are some (many actually) who would disagree.

Okay, what happens or the fact that there is a result can be called or attributed to anything you desire to call it...that is on you. But the fact is that if brass cases sit long enough the necks will split and if the necks don't then the cases might be saved by annealing, but they will still require to be "softened". If they are then they can be used again.

Sounds like a duck, walks like a duck...quacks like a duck, so lets call it a weasel!!!!

Sounds like a duck, walks like a duck...quacks like a duck, so lets call it a weasel!!!!

Just for fun, http://www.accurateshooter.com/technical-articles/x-ray-spectrometry-of-cartridge-brass/

Not all cases are made from 70/30 cartridge brass.

Not all cases are made from 70/30 cartridge brass.

Similar threads

- Replies

- 18

- Views

- 4,451

- Replies

- 17

- Views

- 1,085

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.