Doug Beach

Silver $$ Contributor

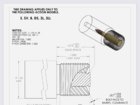

Just utilizing this drawing, with a .223 chamber, I come up with .194” of unsupported case. LC cases seem to have about .185” of solid case head, and Lapua somewhat less.

I know that I don’t have to cut it exactly this way, and I would, of course, not assume the headspace measurement is correct. This isn’t my question.

My question: assuming the chamber is cut according to the drawing, is this amount of unsupported case safe, or unsafe. My bet is on unsafe. What say you?

https://share.icloud.com/photos/0pUKTHN18lDLsEjGMTRWh2FcA

I know that I don’t have to cut it exactly this way, and I would, of course, not assume the headspace measurement is correct. This isn’t my question.

My question: assuming the chamber is cut according to the drawing, is this amount of unsupported case safe, or unsafe. My bet is on unsafe. What say you?

https://share.icloud.com/photos/0pUKTHN18lDLsEjGMTRWh2FcA