Please explain, in detail, how the triangular case "vastly" decreases the needed case length and diameter, while still allowing enough capacity to drive your bullet at the desired velocity. Decreasing internal volume and maintaining a given velocity necessarily means higher pressures. What is the projected operating pressure for this "system"? Earlier, you mentioned (incorrectly) something about the triangular case being able to lower chamber pressure. So you're saying that your case will be smaller in diameter, shorter in length and operate at a lower pressure than a conventional case driving a 125 gr bullet at 2800 fps?

Have you discovered some new propellant?

How will your triangular case grip the round bullet?

How will your bolt lock, given any rotary motion is out of the question because of the triangular case, chamber and case head?

How big, fore and aft, will the grip that houses the magazine be?

Superlatives like "the ultimate" usually signal a high dreaming to engineering ratio.

What is your engineering/design education/background?

Dewey, I apologize if I’ve come across as flippant or a know-it-all. I’m far from an expert and I genuinely appreciate your and others’ feedback.

I went to WVU for 2 years back in 2014 studying engineering, I didn’t finish, and in November of 2020 I completed a certificate in manual machining, and worked in a job shop called DRP machine in West Valley City, Ut. Right now I’m working with a temp agency because this labor shortage has meant better wages than I was getting at Drp.

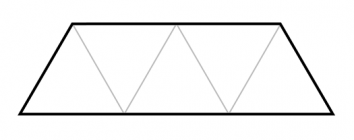

As for the triangular cases, maybe vastly was the wrong word. What I mean by that is that if you have an equilateral triangle with a circle inside that touches the three walls of that triangle then the area of that triangle which isn’t the circle accounts for maybe 30-40% of the internal space of the triangle, to extrapolate that to a 3 dimensional object assuming no taper on the internal case walls the bullet will fill the majority of the space with the largest diameter of its tapered exterior touching the case walls but still leaving a lot of space inside where the bullet doesn’t fit inside the corners of the triangle.

Having these bullets in a staggered configuration like a typical magazine would mean that the cases are taking up the extra space in the magazine that would’ve been just empty space.

I am planning on a .27 diameter projectile, so according to this calculator:

Find out what's the height, area, perimeter, circumcircle, and incircle radius of the regular triangle with this equilateral triangle calculator.

www.omnicalculator.com

For a triangle to have an incircle of .27 the height needs to be .81 that doesn’t account for the thickness of the casing, the walls of the magazine, or the walls of the mag well/grip. If I had to pick values for those I would say that at its thickest point the case would probably be in the ball park of .065” multiply that by 4 because there are 2 case walls on the sides of each case and 2 cases and an extra .005”ø per case for clearance for the bullets to be loaded into the cases and that should mean that the stack of cases are 1.08” wide. I’ll add on .100”x2 for the thickness of the walls of the magazine + .030” for clearance and the loaded magazine should come out to 1.31” the magazine well/grip will need to be pretty thin to accommodate the magazine and still be comfortable, but it really can’t be too thin if it’s expected to survive firing while holding it. The magazine well will probably be made of fiber reinforced nylon and have a wall thickness of .250” plus .025” clearance which would add up to 1.840” which is far too wide to really be comfortable to hold. (Maybe I should reconsider making this thing a traditional rifle.)

The length of the magazine well will need to accommodate the lenth of the case which will have a solid portion around .200” long before the pocket for the bullet and powder, and this bullet diagram (Which is the only one I could find right away) calls out an overall length of 1.49” which would make the case 1.690” +.200” more for the magazine walls+ .030” for clearance inside the magazine + .030” for clearance between the magwell and mag + an extra .500” for the thickness of the walls of the magwell, and suddenly this magazine well seems outside the range of what’s comfortable for the human hand being a roughly rectangular box 2.450” x 1.840”

Okay, I suppose this wouldn’t make sense as a pistol caliber carbine.

I apologize for implying that the triangular case would reduce chamber pressure, what I meant was that having a tandem charge to kick the bullet out into the bore before the main charge lighting would effectively give the gas a greater volume to expand into which could allow for the main charge to use highly energetic pistol powders to really get the bullet moving without jacking up the chamber pressure too much.

For this design I was thinking about using a falling block actuated by a cam path cut into the bolt carrier, and the bullet would have the three flat side of the casing crimped against it. I’m not entirely sure how to calculate the internal volume of the case minus the volume of the bullet. That may or may not be large enough to contain a suitable powder charge.

Edit:Spelling

Edit: I meant no disrespect in liking your posts, those are good questions, and I was working on getting answers to them.