I Use Sweets or, Barnes C-10 to, Remove the Copper, First ( Soak for 20 Min's to Half Hour MAX ). .While looking for copper, check for a carbon ring.

THEN,. BoreTech Eliminator to, Clean Up, the "Throat",.. and, a Little JB's ( One way ) on a Bronze Brush, wouldn't, Hurt, either. ( Clean Thoroughly to, Get the JB's,.. OUT ! )

A Glass Bedded, H-S Precision Stock, IS on, my Most Accurate Rifle ( So Doubt that, the "problem" is, the Stock ).

Hopefully It's been Leveled and Bedded correctly,.. WITHOUT,. "Stress" !

My H-S stock, has been "Bedded" from, One inch of, the Barrels "Shank Portion" to, the Tang and lightly Torqued, and I use, Blue Loctite, on Screws.

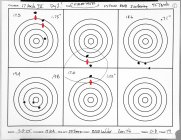

I'm thinking that with, a CLEAN Barrel it's just Now,.. Find the Correct Bullet for the Twist and Do some Seating / Powder "Tuning" ,.. Good Luck !!

Last edited: