Hello, I have posted a few topics pertaining to the 17 fireball. Please bare with me.

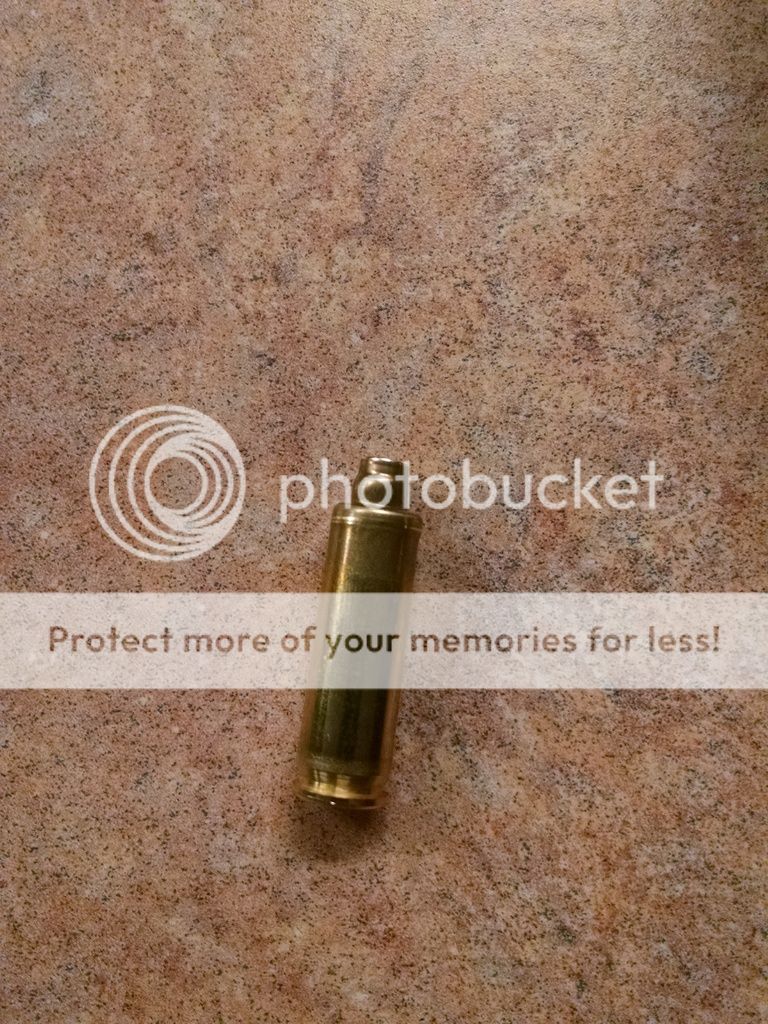

I have brand new lapua 221 fire ball brass I'm forming into 17 fireball.

What I purchased to execute the task at hand is as listed.

Redding 17 fireball deluxe 3 die set # 84204

Redding 17 fireball forming die #1 - #90504

Redding 17 fireball form & trim die #2 - #83504

And redding brand imperial sizing wax..I have used it for years and personally think its the best.

After I run my brass through the dies the end of the case neck seems kind of mushroomed/ or has a slight donut on it if you will, and the end of the case neck is not square anymore. It's longer on one side then the others..that is to say ..if I were to measure the case length with my dial caliper I could get a few different readings by rotating the case( I hope you understand what I'm saying)

It looks like I need to turn case necks, and trim cases to even out the neck and square up the end of the case.

Is this normal? Am I doing something wrong?

Also I got to thinking..mybe I should just finish forming all my cases, the use the cream of wheat case forming method be fore I do anything, like neck turning, or trimming the case square. Ass this is 221 fireball brass formed into 17 fireball the case length is already slightly less then it should be.

Can anyone please direct me towards what I should do..or is this all normal

The k you

I have brand new lapua 221 fire ball brass I'm forming into 17 fireball.

What I purchased to execute the task at hand is as listed.

Redding 17 fireball deluxe 3 die set # 84204

Redding 17 fireball forming die #1 - #90504

Redding 17 fireball form & trim die #2 - #83504

And redding brand imperial sizing wax..I have used it for years and personally think its the best.

After I run my brass through the dies the end of the case neck seems kind of mushroomed/ or has a slight donut on it if you will, and the end of the case neck is not square anymore. It's longer on one side then the others..that is to say ..if I were to measure the case length with my dial caliper I could get a few different readings by rotating the case( I hope you understand what I'm saying)

It looks like I need to turn case necks, and trim cases to even out the neck and square up the end of the case.

Is this normal? Am I doing something wrong?

Also I got to thinking..mybe I should just finish forming all my cases, the use the cream of wheat case forming method be fore I do anything, like neck turning, or trimming the case square. Ass this is 221 fireball brass formed into 17 fireball the case length is already slightly less then it should be.

Can anyone please direct me towards what I should do..or is this all normal

The k you