You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shoulder Bump Issues

- Thread starter copperking81

- Start date

Perhaps more pressure than you think. Norma is on the soft side and not annealing doesn't help. Six times reloaded is asking a lot if the chamber to die match-up is not optimum.Loads are on the higher end of tolerances but not out of line or showing signs of too much pressure.

Sandstorm

Gold $$ Contributor

Send your 2 or 3 time fired brass in and have a custom die made. Also get new brass.

This is your issue. Your brass is expanding further than your die will size it back.

Been there before. just my 2c Sir.

Tell your Machinist your issue at the .200 line and he will know.

This is your issue. Your brass is expanding further than your die will size it back.

Been there before. just my 2c Sir.

Tell your Machinist your issue at the .200 line and he will know.

You could get a small base die or get a cheap Lee die and cut the top off so it doesn't size the shoulder then grind the bottom until you get the size reduction you need.

who makes the smallest 300 wsm die (base size)

pretty simple who makes the smallest dia base of the current production sizing dies. my current die , a redding, is not quite small enough to get a true bolt free drop. a very minor closing is required and works but i would like to get smaller without getting shorter thanksforum.accurateshooter.com

That's a good thread, thanks for sharing! I might give the Wilson a try. Sounds like that fixed a similar problem he had.

Any possibility you are pushing/pulling a mandrel through the necks after you measure your sized brass and the mandrel is pulling the neck & shoulders back up?

Hank

Hank

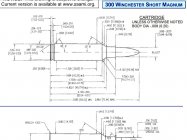

SAAMI drawing has the maximum loaded cartridge at .555" . The barrels chamber may be on the tight side?When I measure at the 200 line (a new concept / term to me... thanks), I get the following...

- Fired brass, shoulder bumped .002 (chambers very tight) = .553

- Fired brass, shoulder bumped .020 (chambers fine) = .551

- New unfired brass (chambers fine) = .549

Get a single stage press that uses a standard shell holder. When sizing, at top of the stroke, the shell holder should make full contact with the bottom of the Fl die.

Your current setup should not allow .020" room for adjustment.

A standard die set up will provied around .005" shoulded set back.

Last edited:

What got my attention was the aftermarket barrel. It may not be cut to SAMMI spec which commercial dies are set up to size for.

Check the chamber with SAMMI go / no go gauges. On the surface, this sounds like the die is not compatible with the rifle chamber.

I agree, you need to get the root cause of this issue. I would consult an experienced rifle smith and have the chamber inspected.

Check the chamber with SAMMI go / no go gauges. On the surface, this sounds like the die is not compatible with the rifle chamber.

I agree, you need to get the root cause of this issue. I would consult an experienced rifle smith and have the chamber inspected.

Wow! That's a great way to work around having a die that's fatter than your chamber. I currently have a 7mm rem mag that does this with the Hornady die that I use for it. I was considering buying a small base die, but that sounds much cheaper and easier.or get a cheap Lee die and cut the top off so it doesn't size the shoulder then grind the bottom until you get the size reduction you need.

For those without metalworking tools, maybe not so much...

Has any corrections/equipment been made/changed?Your current setup should not allow .020" room for adjustment.

Has any corrections/equipment been made/changed?

Not yet. I sent the die back to Redding to analyze and I'm waiting to hear back. That's where I'm at.

Measure expansion at the .200" line. Try a lighter charge.I have a 300 WSM that after shoulder bumping fired brass back .002 inches with a FL sizing die, is still a pain to chamber. In fact, the resistance doesn't start to feel normal until I take it down .020 inches shoulder bump (fired = 1.730. Sized to comfortable chambering = 1.710). I'm measuring with a Sincliar bump gauge and digital calipers. Rifle is a Model 70 with a Bartlein barrel. Loads are on the higher end of tolerances but not out of line or showing signs of too much pressure. Die is a FL Redding.

Thoughts on why that might be? The gun will chamber with the minimal bump but it takes some effort. My biggest concern is I don't want to gal the lugs or damage the gun.

Redding got back to me. Along with the die, I sent them three sample sets of brass... 1) two fired unsized cases, 2) two fired and sized cases shoulder bumped back by .002 and would not chamber and 3) two fired and sized cases with the minimum shoulder bump required to chamber (bumped by .020). I took these measurements with two different calipers using a Sinclair bump gauge insert.

Redding measured the cases with an optical comparator and got different measurements than I did...

Redding measured the cases with an optical comparator and got different measurements than I did...

- The sized cases where I measured the shoulder bump as .002 had actually had grown in length after sizing. Apparently that can happen if the die isn't seated far enough. I wouldn't have known because my measurements showed .002 inch bump and to the naked eye, the die looked pretty close to seated.

- The sized cases where I measured the shoulder bump as .020 were only bumped back by ~.007.

Buy once cry once...save yourself more headaches and get a SAC comparator.

Are malformed comparators a regular problem? I'm not opposed to spending the money on quality comparators. I assumed the Sinclair branded were likely pretty good.

6BRA

Gold $$ Contributor

These will fit your case shoulders very well. JMO The will in turn center the brass on your caliper effortlessly.Are malformed comparators a regular problem? I'm not opposed to spending the money on quality comparators. I assumed the Sinclair branded were likely pretty good.

Similar threads

- Replies

- 91

- Views

- 8,646

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.